What Are the Best Uses for Leak-Proof Paint?

Introduction

Water damage is one of the most common and costly issues in construction, affecting rooftops, basements, walls, and industrial structures. Traditional waterproofing methods often fail due to cracking, poor adhesion, premature aging, and environmental exposure, leading to frequent repairs and increased maintenance costs.

Leak-proof paint has emerged as an innovative solution, offering seamless, highly durable, and easy-to-apply waterproof protection for a wide range of construction projects. From commercial buildings and infrastructure to residential properties, leak-proof paint ensures long-lasting protection against water infiltration, weather damage, and chemical corrosion.

In this article, we’ll explore:

✔ Why traditional waterproofing solutions fail

✔ How leak-proof paint solves common waterproofing challenges

✔ The best applications for leak-proof paint in construction

✔ Common waterproofing issues and expert-recommended solutions

✔ Real-world case studies using YURU Waterproof products

By the end of this article, you’ll understand how leak-proof paint can enhance waterproofing efficiency, extend building lifespan, and reduce long-term maintenance costs.

Why Do Traditional Waterproofing Solutions Fail?

Despite the availability of waterproofing materials, many construction projects continue to experience leaks, water damage, and premature degradation. Below are the primary reasons why traditional solutions fail:

1. Frequent Water Leakage

Water infiltration is a major issue in areas constantly exposed to rain, humidity, and hydrostatic pressure, such as rooftops, basements, and exterior walls. Traditional waterproofing layers develop cracks and weak points, allowing water to seep through.

- Rooftops: Cracking due to thermal expansion and contraction.

- Basements: High water pressure forces leaks through porous surfaces.

- Exterior Walls: Rain and humidity cause seepage, leading to paint deterioration and mold growth.

2. Short Lifespan and Rapid Aging

Many waterproofing materials degrade within 3 to 7 years, requiring frequent reapplications and increasing long-term maintenance costs.

| Waterproofing Material | Average Lifespan | Common Issues |

| Asphalt-Based Coatings | 3-5 years | Cracking, UV degradation |

| Cementitious Coatings | 5-7 years | Brittle, prone to shrinkage |

| Bitumen Sheets | 5-7 years | Weak bonding, leak formation |

| Leak-Proof Paint | 10+ years | Highly flexible, UV & weather-resistant |

3. Difficult and Time-Consuming Application

- Requires a completely dry surface, making rainy or humid conditions unsuitable.

- Multi-layer application needed, extending project timelines.

- Requires specialized labor, increasing installation costs.

4. High Long-Term Costs

Although some traditional waterproofing materials may have a lower upfront cost, their short lifespan and frequent maintenance requirements make them more expensive in the long run.

| Solution Type | Initial Cost | Maintenance Cost Over 10 Years | Overall Cost Efficiency |

| Low-Quality Waterproofing | Low | High (frequent repairs) | Poor |

| Mid-Range Waterproofing | Moderate | Medium (some maintenance) | Average |

| Leak-Proof Paint | High | Low (minimal repairs) | Excellent |

How Leak-Proof Paint Solves Waterproofing Challenges?

Leak-proof paint provides a next-generation waterproofing solution designed to eliminate the weaknesses of traditional methods. It offers:

1. Superior Waterproofing Protection

- Forms a seamless, crack-free barrier.

- Seals microcracks and prevents leaks.

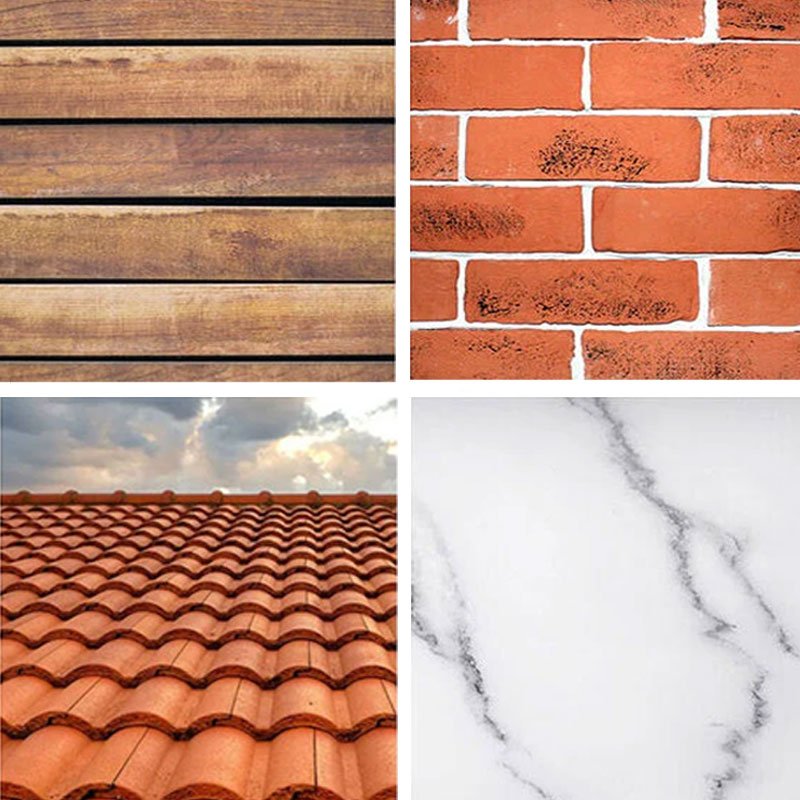

- Strong adhesion to multiple surfaces (concrete, metal, wood, etc.).

2. Long Lifespan & High Weather Resistance

- UV-resistant, prevents premature aging.

- Resists acid rain, pollution, and extreme temperatures.

- Lasts over 10 years without degradation.

3. Fast & Easy Application

- Can be applied on damp surfaces, eliminating the need for drying.

- Suitable for brush, roller, or spray application.

- Reducing project completion time.

4. Cost-Effective Maintenance

- Requires minimal reapplication, reducing long-term costs.

- Stronger adhesion = fewer repairs needed

Leak-Proof Paint Solutions for Different Construction Scenarios

Choosing the right leak-proof paint depends on the specific challenges of each construction site. Below are the best leak-proof paint solutions for different applications:

1. Roof Waterproofing – Preventing Cracks and Ponding Issues

Roofs are constantly exposed to rain, UV radiation, and temperature fluctuations, which can cause cracks and water accumulation, leading to leaks and structural damage.

Recommended Solution: High-Elastic Polyurethane Leak-Proof Paint

✔ Forms a seamless waterproof layer, preventing rainwater infiltration

✔ High elasticity accommodates thermal expansion and contraction

✔ UV-resistant to prevent degradation and aging

| Roof Issue | Common Cause | Leak-Proof Paint Solution |

| Cracking | Thermal expansion/contraction | High-flexibility polyurethane paint |

| Ponding Water | Poor drainage/sloped design | Waterproof coating with self-leveling properties |

| UV Damage | Prolonged sun exposure | UV-resistant, weatherproof paint |

2. Basement & Tunnel Waterproofing – Handling Underground Water Pressure

Basements and tunnels face constant exposure to groundwater and hydrostatic pressure, which can lead to leaks, dampness, and structural deterioration.

Recommended Solution: Penetrating or High-Polymer Leak-Proof Paint

✔ Deeply penetrates concrete surfaces, forming a waterproof barrier

✔ Resistant to high water pressure, preventing seepage

✔ Bonds strongly with concrete, ensuring long-term durability

| Underground Challenge | Effect on Structure | Leak-Proof Paint Solution |

| Hydrostatic Pressure | Forces water through cracks | High-polymer waterproof paint with pressure resistance |

| Capillary Action | Moisture rises through porous surfaces | Penetrating leak-proof paint to block moisture |

| Mold & Mildew Growth | High humidity in enclosed spaces | Anti-microbial waterproof coating |

3. Exterior Wall Waterproofing – Protection Against Rain and Humidity

Exterior walls are continuously exposed to rain, wind, and temperature changes, leading to water infiltration, mold growth, and paint deterioration.

Recommended Solution: Weather-Resistant Transparent Leak-Proof Paint

✔ Forms an invisible protective layer without altering the building’s appearance

✔ Highly breathable – prevents trapped moisture while blocking external water

✔ UV and pollution-resistant for long-term durability

4. Bathroom & Kitchen Waterproofing – Preventing Moisture and Mold Growth

Bathrooms and kitchens are high-moisture environments, making them prone to water leaks, mold, and tile damage.

Recommended Solution: Anti-Mold and Anti-Bacterial Leak-Proof Paint

✔ Waterproof and moisture-resistant, preventing seepage into walls

✔ Contains anti-microbial agents to prevent mold and mildew growth

✔ Strong adhesion to tiled surfaces, improving longevity

5. Bridge & Water Infrastructure Waterproofing – Extreme Condition Protection

Bridges, dams, and water-related structures face extreme weather conditions, constant water exposure, and chemical corrosion, requiring high-performance waterproofing.

Recommended Solution: Corrosion-Resistant & UV-Protected Leak-Proof Paint

✔ Provides exceptional resistance to harsh weather, water, and chemicals

✔ Prevents rust and degradation in metal and concrete structures

✔ UV-resistant for long-lasting durability in exposed areas

| Infrastructure Issue | Environmental Stress | Leak-Proof Paint Solution |

| Concrete Degradation | Constant water & salt exposure | Corrosion-resistant waterproof paint |

| Rust Formation | Moisture and oxidation | Anti-rust, weatherproof paint |

| UV & Temperature Fluctuations | High sun exposure | UV-resistant waterproof coating |

Real-World Applications – YURU Waterproof Leak-Proof Paint in Action

1. High-Rise Building Exterior Wall Waterproofing

Problem: Rain penetration was causing paint peeling and structural dampness.

- Solution: Transparent leak-proof paint, ensuring aesthetic preservation and long-term protection.

- Result: Zero leakage for 15+ years, reducing maintenance costs.

2. Underground Parking Garage Leakage Repair

Problem: Groundwater seepage led to cracks and moisture accumulation.

- Solution: Deep-penetrating waterproof paint + crack injection materials.

- Result: Completely sealed cracks, preventing further leaks.

3. Commercial Rooftop Waterproofing Upgrade

Problem: Cracked roof caused water accumulation and mold issues.

- Solution: High-elasticity polyurethane leak-proof paint.

- Result: 10+ years durability, ensuring zero water infiltration.

4. Metro Tunnel Waterproofing Project

Problem: Constant exposure to underground water pressure.

- Solution: Water pressure-resistant leak-proof paint.

- Result: 100% reduction in water seepage, reducing tunnel maintenance.

5. Wastewater Treatment Plant Protection

Problem: Severe chemical corrosion from industrial wastewater.

- Solution: Acid & alkali-resistant epoxy waterproof paint.

- Result: 5x longer lifespan compared to traditional coatings.

Conclusion

Effective waterproofing is essential in construction projects to prevent structural damage. Traditional waterproofing methods often fail due to cracking, poor adhesion, rapid aging, and chemical degradation.

However, leak-proof paint provides an advanced solution that overcomes these challenges with superior flexibility, high weather resistance, and long-lasting protection.

YURU leak-proof paint offers a cost-effective, durable, and efficient alternative to traditional waterproofing solutions.

- Superior waterproofing for diverse applications.

- UV, chemical, and weather resistance for long-lasting performance.

- Easy application & minimal maintenance requirements.

- Proven effectiveness in large-scale construction projects.

For professional waterproofing solutions, contact YURU Waterproof today and ensure long-lasting protection for your construction projects.