What is Chemical Injection Waterproofing?

What is Chemical Injection Waterproofing?

Chemical injection waterproofing technology is an efficient and long-lasting waterproofing solution that is widely used in construction projects. Whether it is a basement, tunnel or pool, this technology can effectively solve the leakage problem.

This article will introduce the basic principles, application scenarios, core advantages, common problems and solutions of chemical injection waterproofing in detail, and provide you with practical suggestions for choosing the right material.

The Basic Principles of Chemical Injection Waterproofing

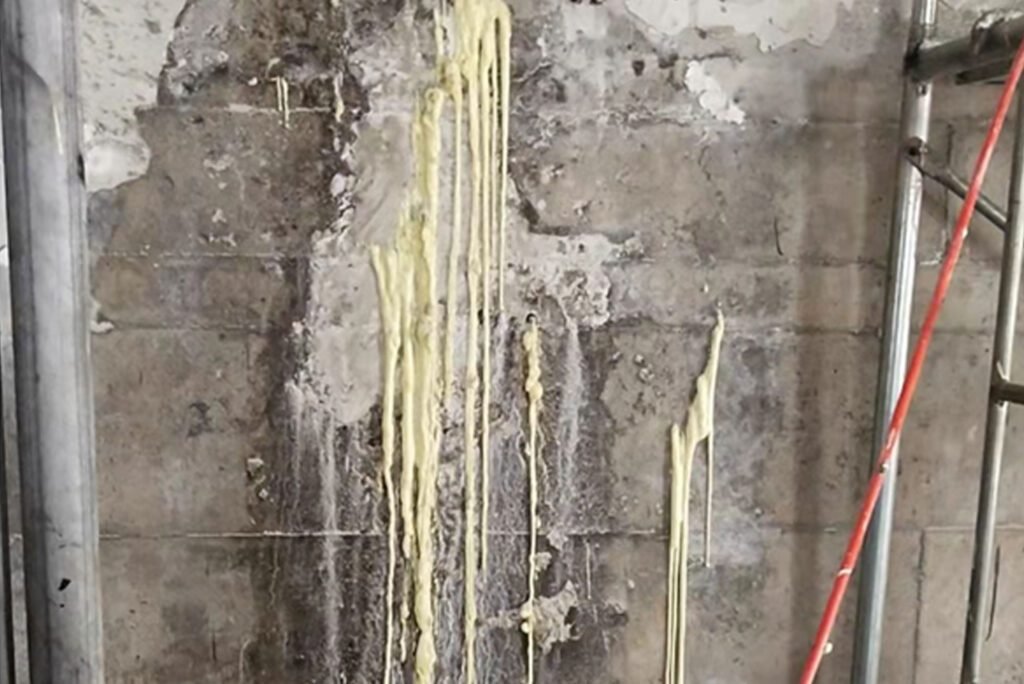

Chemical injection waterproofing involves injecting specialized chemical grouts into cracks or pores in concrete using high-pressure equipment. After curing, the slurry forms a strong waterproof layer, thereby preventing water from penetrating.

This technology is particularly suitable for repairing leakage problems in complex structures, such as basement walls, tunnel linings, and pool bottoms.

YURU Waterproof’s chemical grouting material has the characteristics of high permeability and fast curing, and can penetrate deep into fine cracks to ensure a long-lasting and reliable waterproofing effect.

Applications of Chemical Injection Waterproofing in Construction Projects

Chemical injection waterproofing plays a vital role in various construction scenarios:

Basement Waterproofing: Resolves leaks caused by high groundwater levels, protecting structural integrity.

Tunnel Engineering: Repairs cracks in tunnel linings, prevents groundwater infiltration, and ensures tunnel safety.

Water Tanks and Reservoirs: Ensure the tightness of water storage structures to prevent water waste.

Building Exterior Waterproofing: Addresses leaks due to aging or construction defects, extending the building’s lifespan.

YURU Waterproof offers customized injection materials tailored to different scenarios, meeting diverse customer needs.

Core Advantages of Chemical Injection Waterproofing

Efficiency: Chemical grouts penetrate and cure quickly, forming a waterproof layer in a short time.

Durability: Cured materials exhibit excellent compressive and anti-seepage properties, ensuring long-term performance.

Versatility: Suitable for various substrates, including concrete and masonry.

Eco-Friendliness: YURU Waterproof’s materials comply with environmental standards, posing no harm to the environment or human health.

Cost-Effectiveness: Compared to traditional methods, chemical injection waterproofing offers lower overall costs.

Common Issues and Solutions in Chemical Injection Waterproofing

Issue: Uneven Grout Penetration

Solution: Adjust injection pressure to ensure even distribution.

Issue: Curing Time Too Long or Too Short

Solution: Select grout materials based on ambient temperature and humidity.

Issue: Leakage Persists After Injection

Solution: Check if cracks are fully filled and perform secondary injection if necessary.

Issue: Poor Adhesion Between Material and Substrate

Solution: Clean the substrate surface to remove dust and impurities.

YURU Waterproof provides professional technical support to help customers overcome construction challenges.

How to Choose the Right Chemical Injection Waterproofing Materials

Select Materials Based on Project Requirements

For example, basement waterproofing requires highly permeable materials, while tunnel engineering demands high compressive strength.

Consider Environmental Factors

Temperature, humidity, and water quality can affect material performance.

Choose a Reliable Supplier

YURU Waterproof offers high-quality customized grout materials with detailed technical guidance.

Test Material Performance

Conduct small-scale tests before full-scale application to ensure suitability.

Prioritize After-Sales Service

Opt for brands that provide technical support and after-sales services for a hassle-free experience.

Conclusion

Chemical injection waterproofing is an indispensable solution in modern construction projects. By understanding its principles, applications, and advantages, you can select the most suitable waterproofing materials for your project.

YURU Waterproof is committed to providing high-quality customized grout materials and professional technical support, helping you tackle waterproofing challenges with ease.

If you’re looking for a reliable chemical injection waterproofing solution, contact YURU Waterproof today for top-notch service!

YURU Product solutions

Waterproof Coating

- One-component oil-based polyurethane waterproof coating

- One-component water-based polyurethane waterproof coating

- Two-component polyurethane waterproof coating

- Two-component 6.0Mpa polyurethane waterproof coating

- Transparent Waterproof Glue

- Nano Invisible Waterproof Agent

- Silicone Waterproof Coating

- Acrylic Waterproof Coating For Metal Roof

- JS Polymer Waterproof Coating

- High Elastic Liquid Rubber Waterproof Coating

- Cement-based Penetrating Crystallization Waterproof Coating