What’s the Difference Between Coating and Waterproof Membrane?

In the world of construction and waterproofing, choosing the right waterproofing method is critical to a project’s long-term durability. Two of the most commonly used systems are liquid waterproof coatings and waterproof membranes. While both aim to protect surfaces from water intrusion, they differ significantly in application, performance, and ideal use cases.

In this article, we’ll break down the key differences and guide you on how to select the best solution for your construction or waterproofing project.

Definition: What Are Waterproof Coatings vs. Membranes?

- Waterproof Coating is a liquid-applied material that cures to form a seamless and elastic waterproof barrier. Common examples include polyurethane, acrylic, or epoxy-based coatings.

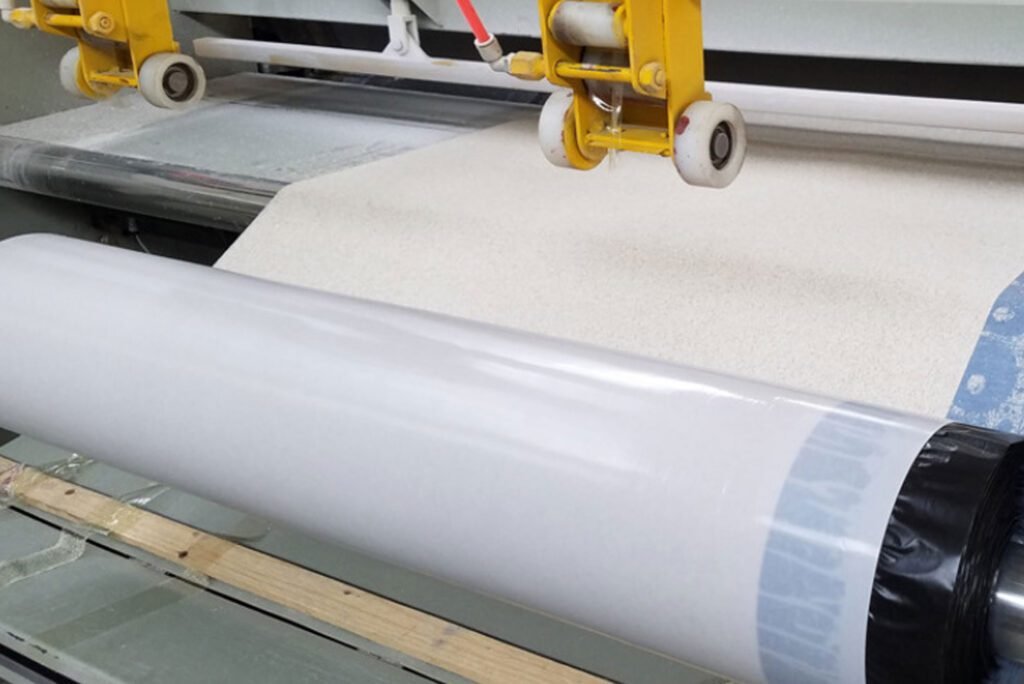

- Waterproof Membrane refers to pre-formed sheets (like PVC, TPO, or self-adhesive bitumen) that are laid or torch-applied onto surfaces to create a waterproof layer.

Key takeaway: Coatings are applied as a liquid; membranes are pre-manufactured sheets.

Application Method: Spray, Roll or Torch?

- Coatings are applied using a roller, brush, or spray equipment directly onto concrete, metal, or roofing substrates. They conform easily to complex shapes and details.

- Membranes, depending on the type, require mechanical fastening, adhesive, or torching. Installation requires more planning and surface preparation.

Tip: Coatings are faster for irregular surfaces; membranes offer uniform thickness and strength.

Thickness & Durability

- Liquid Coatings typically form a thinner layer (0.5–2 mm), but certain polyurethane types can build up thickness.

- Membranes are usually 1.2 mm–4 mm thick and offer consistent protection across the surface.

Consideration: For areas prone to mechanical wear or foot traffic, membranes are more impact-resistant; for flexible sealing around joints or corners, coatings excel.

Common Applications

Use Coatings for:

- Roofs with complex geometries

- Concrete decks and balconies

- Waterproofing under tiles

- Maintenance and repairs

Use Membranes for:

- Large flat roofs

- Foundation and basement walls

- Tunnel and bridge structures

- Wet areas like bathrooms and kitchens

Which Is Better for Your Project?

There’s no one-size-fits-all answer. The right choice depends on:

- Substrate condition

- Project scale

- Expected water exposure

- Required durability

- Installation equipment and time

For small-scale or irregular areas, YURU Waterproof Coatings (such as polyurethane liquid membranes) offer excellent flexibility and ease of use. For large-scale industrial or below-grade applications, YURU Waterproof Membranes provide superior tensile strength and puncture resistance.

Why Choose YURU Waterproof as Your Supplier?

YURU Waterproof is a trusted manufacturer of high-performance waterproofing materials, specializing in both liquid-applied coatings and sheet membranes. We offer:

- Custom OEM / ODM services.

- Over 20 years of export experience.

- ISO, CE, and EPR certified products.

- Professional support for construction projects.

Whether you need coatings, membranes, or expert advice on which is right for your project, our team is here to support you with fast delivery, global logistics, and technical training.

Conclusion

Understanding the difference between waterproof coatings and membranes is key to successful waterproofing. Each has its advantages depending on the application scenario. If you’re still unsure which solution best fits your needs, reach out to YURU Waterproof — your professional partner in durable, high-performance waterproofing systems.

YURU Product solutions

Waterproof Coating

- One-component oil-based polyurethane waterproof coating

- One-component water-based polyurethane waterproof coating

- Two-component polyurethane waterproof coating

- Two-component 6.0Mpa polyurethane waterproof coating

- Transparent Waterproof Glue

- Nano Invisible Waterproof Agent

- Silicone Waterproof Coating

- Acrylic Waterproof Coating For Metal Roof

- JS Polymer Waterproof Coating

- High Elastic Liquid Rubber Waterproof Coating

- Cement-based Penetrating Crystallization Waterproof Coating