Bridge and Tunnel Polyurea Grouting Material

Introduction

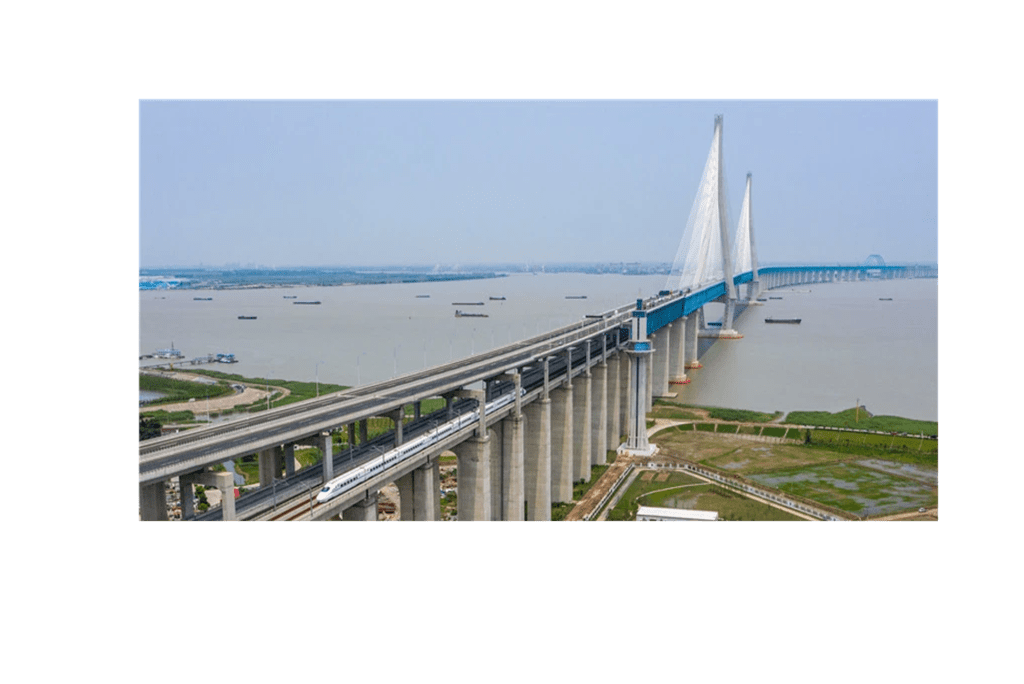

Bridges and tunnels are essential components of modern infrastructure, but they’re constantly exposed to environmental stress: temperature fluctuations, heavy loads, water ingress, and ground movement. Over time, joints, seams, and cracks begin to fail—resulting in dangerous leaks or long-term structural damage.

This is where bridge and tunnel polyurea grouting material comes in. Unlike rigid sealants, polyurea grout provides flexibility, waterproofing, and strong adhesion—even in wet environments. It’s ideal for large-scale civil engineering repair and waterproofing.

What Is Polyurea Grouting Material?

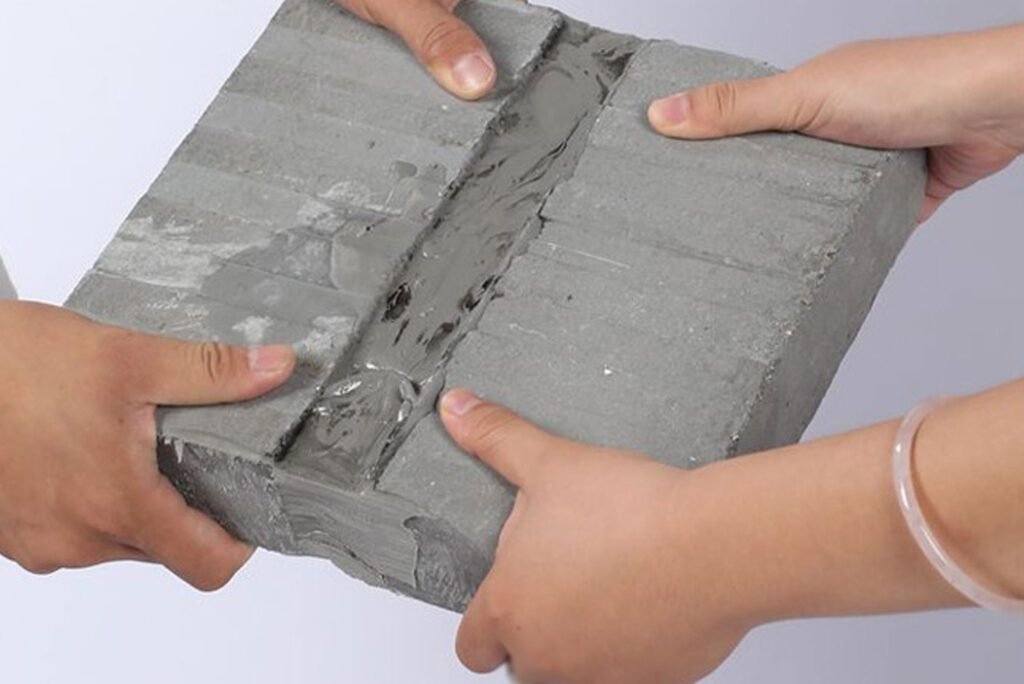

Polyurea grouting is injection material made from isocyanate and amine resins. Once injected, it reacts within minutes to form a durable, elastic, and waterproof seal inside cracks or joints.

YURU Waterproof’s polyurea grout products are formulated to handle dynamic movement and harsh environmental conditions often encountered in tunnels and bridge decks.

Key Features of Polyurea Grouting for Bridge and Tunnel Projects

High Elasticity and Crack Movement Tolerance

Bridges and tunnels shift—expansion joints stretch, concrete segments settle. Polyurea grout can elongate over 500% and return to its original shape, ensuring lasting performance even under structural motion.

Fast Curing in Wet Environments

Our polyurea grout cures in damp, wet, or actively leaking cracks. This makes it especially suitable for underground tunnels, subways, and bridge undersides.

Excellent Bonding on Damp Concrete

Unlike traditional materials, polyurea grout adheres strongly to moist or water-affected surfaces. No need to wait for concrete to dry—a major advantage in time-sensitive repairs.

Common Application Areas in Bridge and Tunnel Structures

Expansion Joints and Segmental Tunnel Linings

- Seal and reinforce bridge expansion joints.

- Inject into tunnel ring segments (precast concrete).

- Repair settlement or shrinkage cracks in concrete linings.

Leaking Pipe Penetrations and Drainage Channels

- Seal pipe entries, utility conduits, and weep holes.

- Waterproof drainage lines under bridges.

- Reinforce areas vulnerable to hydrostatic pressure.

YURU Waterproof offers project-specific formulations for all these use cases, ensuring long-term leak prevention and structural safety.

How Polyurea Grout Compares to Traditional Grouting Materials?

| Property | Polyurea Grout | PU/Epoxy Grout |

| Elasticity | Very High | Low to Moderate |

| Bond Strength (wet) | Excellent | Limited |

| Application Conditions | Works on damp surfaces | Requires dry surfaces |

| Environmental Impact | Low-VOC, solvent-free | Some solvents, odor |

YURU’s polyurea solutions are not only better-performing—they’re safer and more efficient to apply.

Installation Process: Efficient and Professional Application

A standard application includes the following steps:

- Surface prep – Clean the crack, remove debris or weak concrete.

- Drill injection holes – For deep cracks or sealed joints.

- Install injection packers – Ensure sealed and controlled flow.

- Use injection pump – Inject materials.

- Wait for curing – Wait for curing before trimming or sealing surface.

YURU Waterproof offers technical manuals, remote guidance, and video training for safe and effective grout installation.

Why Choose YURU Waterproof as Your Grouting Material Supplier?

At YURU Waterproof, we understand the critical demands of bridge and tunnel maintenance. That’s why we provide:

- Customizable formulations based on environmental and structural conditions.

- Bulk and small-volume supply options for different project scales.

- OEM/private label services for international partners.

- Full export documentation, including MSDS, and test reports.

- Fast lead times and global logistics support.

Our polyurea products have been trusted in metro tunnels, expressways, and international infrastructure projects across Asia, the Middle East, and Europe.

FAQs – Bridge and Tunnel Polyurea Grout

1. What is the service life of polyurea grouting?

Typically 15–25 years depending on environmental conditions and application quality.

2. Is it suitable for high-pressure injection?

Absolutely. Our material withstands pressure ≥1.5 MPa and is ideal for deep injection.

3. Do you offer site-specific customization?

Yes, we tailor viscosity, reaction time, and bonding strength based on your needs.

4. Can I order OEM packaging or branded containers?

Yes. YURU Waterproof supports full OEM and ODM partnerships globally.

5. Is training available for installation teams?

We provide detailed manuals, training videos, and remote tech support for international clients.

Conclusion

When it comes to infrastructure maintenance, quality and speed matter. Bridge and tunnel polyurea grouting material from YURU Waterproof is the smart choice for structural crack sealing, waterproofing, and long-term performance.

Whether you’re sealing a metro tunnel, bridge joint, or underground culvert—our products deliver strength, flexibility, and durability under pressure.

Contact YURU Waterproof today to request a quote, technical specs, or sample kit. We’re your trusted partner for advanced grouting and waterproofing solutions.

Visit us at: https://yuruwaterproof.com

YURU Product solutions

Waterproof Coating

- One-component oil-based polyurethane waterproof coating

- One-component water-based polyurethane waterproof coating

- Two-component polyurethane waterproof coating

- Two-component 6.0Mpa polyurethane waterproof coating

- Transparent Waterproof Glue

- Nano Invisible Waterproof Agent

- Silicone Waterproof Coating

- Acrylic Waterproof Coating For Metal Roof

- JS Polymer Waterproof Coating

- High Elastic Liquid Rubber Waterproof Coating

- Cement-based Penetrating Crystallization Waterproof Coating