Advantages of Epoxy Floor Paint in Industrial Projects

Introduction

Industrial flooring plays a critical role in ensuring efficiency, safety, and long-term performance in large-scale projects such as warehouses, factories, logistics centers, and heavy-duty production facilities. Choosing the right floor coating directly impacts operational reliability, maintenance costs, and the overall image of a project.

Epoxy floor paint has become one of the most widely adopted solutions in industrial flooring due to its durability, chemical resistance, safety features, and aesthetic appeal. For contractors, wholesalers, and project managers, epoxy floor paint offers reliable advantages that extend far beyond simple surface protection.

In this article, we will explore the key benefits of epoxy floor paint in industrial projects, real-world application scenarios, and how YURU Waterproof supports partners with customized solutions and stable delivery.

High Durability for Heavy-Duty Industrial Needs

Industrial flooring must withstand constant stress from heavy machinery, forklifts, high traffic, and long-term load-bearing. Traditional cement floors often develop cracks, dust, or wear quickly under such conditions.

Epoxy floor paint offers exceptional hardness and wear resistance. Once cured, it creates a seamless and tough surface that can withstand years of mechanical pressure. This makes it an ideal choice for:

- Manufacturing plants with continuous machine operations.

- Warehouses storing heavy pallets and goods.

- Logistics hubs with 24/7 forklift traffic.

By reducing repair frequency and extending service life, epoxy coatings significantly lower long-term maintenance costs for contractors and project owners.

Chemical Resistance for Safer Industrial Environments

Many industrial projects deal with chemicals, solvents, oils, or cleaning agents that can easily damage untreated concrete floors. Once these substances penetrate the surface, they may cause erosion, contamination, or costly structural damage.

Epoxy floor paint provides excellent resistance to chemical spills, acids, alkalis, and oils. This feature ensures:

- Reduced risk of chemical damage.

- Easier cleanup of spills.

- Safer and cleaner working conditions.

For industries such as pharmaceuticals, automotive manufacturing, or chemical processing, chemical resistance is not only a convenience but a regulatory requirement. Epoxy coatings help meet these safety and compliance standards.

Dust-Free and Anti-Slip Features for Safety

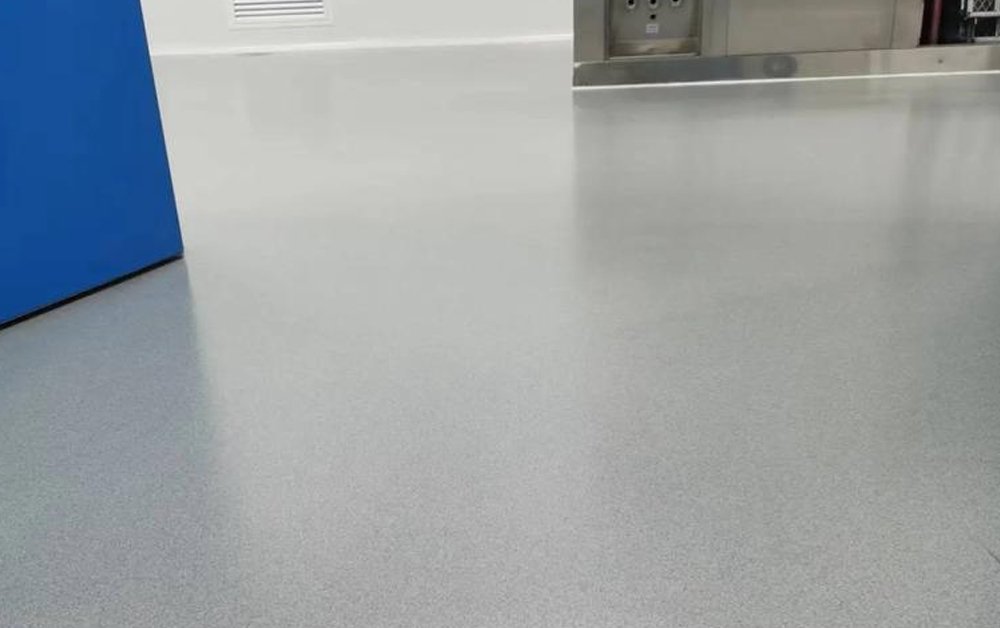

Safety is always a top concern in industrial projects. Dust accumulation on concrete floors can cause contamination in sensitive industries, while slippery surfaces may lead to accidents.

Epoxy floor paint creates a dust-free and easy-to-clean surface. Additionally, contractors can choose anti-slip finishes to improve traction in areas with high foot traffic or liquid exposure. This ensures:

- Reduced risk of workplace accidents.

- Higher employee safety and productivity.

- Compliance with occupational safety standards.

In industries such as food processing or logistics, where clean and safe surfaces are crucial, epoxy flooring offers a practical and reliable solution.

Fast Installation and Project Efficiency

For contractors and project managers, minimizing downtime is essential. Every additional day of floor installation may result in production delays and financial losses.

Epoxy floor paint offers a relatively fast curing process, especially compared to traditional flooring systems. This reduces project timelines and allows contractors to deliver projects more efficiently. For clients, shorter downtime means reduced operational disruptions and earlier resumption of business activities.

This makes epoxy coatings highly valuable in renovation projects or in facilities that cannot afford extended closures.

Aesthetic Appeal and Professional Image

Industrial flooring is not only about durability but also about creating a professional, modern, and appealing environment.

Epoxy floor paint comes in a wide range of colors, finishes, and effects, allowing contractors and project owners to align floor designs with brand identity or functional zoning. For example:

- Different colors for production areas, walkways, and safety zones.

- Glossy finishes to enhance brightness in warehouses.

- Decorative finishes for commercial showrooms.

By improving the overall appearance of the facility, epoxy coatings contribute to brand image and property value.

Real-World Applications and Long-Term Value

Epoxy floor paint has already been widely applied in diverse industrial settings such as:

Heavy-duty manufacturing plants

- Warehousing and logistics centers

- Food and pharmaceutical production areas

- Commercial showrooms and public facilities

In each of these environments, epoxy coatings have demonstrated cost efficiency, safety benefits, and operational reliability.

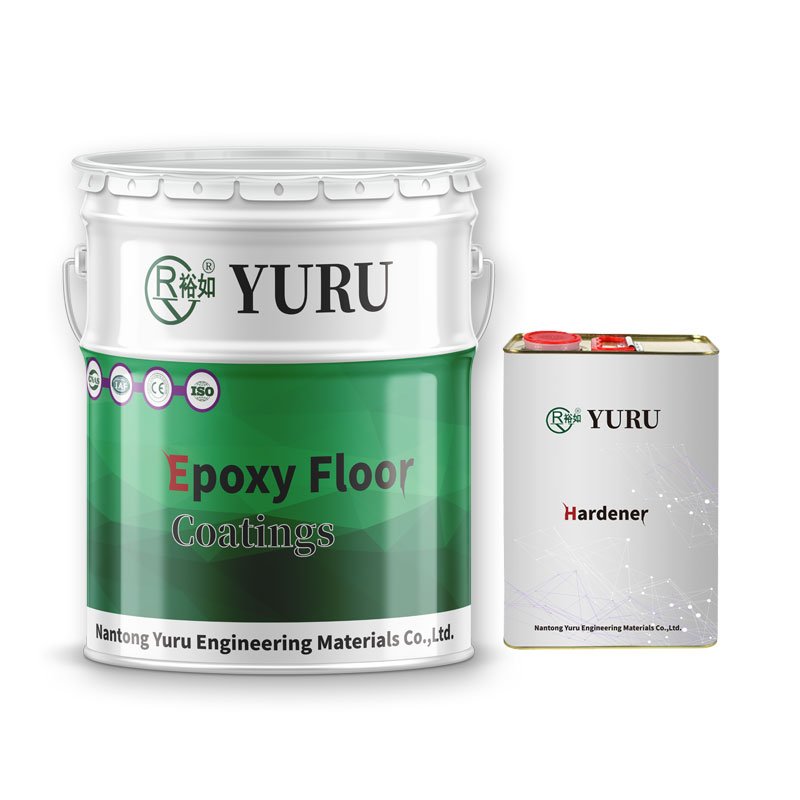

At YURU Waterproof, we support global partners by delivering epoxy floor paint solutions tailored to their project requirements. Our expertise lies not only in product performance but also in stable supply, flexible customization, and strong after-sales support — ensuring that wholesalers, contractors, and project managers can rely on long-term value.

Conclusion

Epoxy floor paint has become the preferred choice for industrial flooring projects worldwide, thanks to its durability, chemical resistance, safety features, and design versatility. For customers — including wholesalers, contractors, and large project owners — epoxy flooring represents a cost-effective and long-lasting solution that supports both functionality and aesthetics.

With a strong track record in delivering customized epoxy and waterproofing materials, YURU Waterproof continues to empower partners with reliable products, stable delivery, and engineering support.

FAQs

1: Why is epoxy floor paint better than traditional concrete floors?

Epoxy offers greater durability, resistance to chemicals, and dust-free surfaces, reducing long-term maintenance costs compared to untreated concrete.

2: How long does epoxy floor paint last in industrial projects?

With proper application and maintenance, epoxy coatings can last 10–15 years, even under heavy-duty conditions.

3: Can epoxy floor paint be customized for different industrial needs?

Yes. At YURU Waterproof, epoxy coatings can be tailored in terms of color, finish, and performance features (e.g., anti-slip, chemical resistance).

4: How fast can epoxy floor paint be installed?

Installation time depends on project size, but epoxy coatings generally cure faster than traditional flooring systems, minimizing downtime.

5: Is epoxy floor paint suitable for food or pharmaceutical industries?

Yes. Its seamless, non-porous, and easy-to-clean surface meets hygiene standards, making it ideal for sensitive production environments.

YURU Product solutions

Waterproof Coating

- One-component oil-based polyurethane waterproof coating

- One-component water-based polyurethane waterproof coating

- Two-component polyurethane waterproof coating

- Two-component 6.0Mpa polyurethane waterproof coating

- Transparent Waterproof Glue

- Nano Invisible Waterproof Agent

- Silicone Waterproof Coating

- Acrylic Waterproof Coating For Metal Roof

- JS Polymer Waterproof Coating

- High Elastic Liquid Rubber Waterproof Coating

- Cement-based Penetrating Crystallization Waterproof Coating