Seamless Polyurethane Waterproofing Coatings for Concrete Structures

Introduction

In modern construction, concrete durability and waterproofing performance are crucial for long-term building integrity. Traditional waterproofing systems, such as membranes or asphalt-based coatings, often suffer from weak adhesion, cracks, or joint failures over time.

To solve these challenges, engineers and contractors are turning to seamless polyurethane waterproofing coatings—an advanced solution that forms a continuous, joint-free barrier across concrete surfaces.

With outstanding elasticity, adhesion, and environmental resistance, this system ensures watertight protection even under extreme stress, making it ideal for both new construction and renovation projects.

This article explores what seamless polyurethane waterproofing is, how it works, its applications, technical performance, and why YURU Waterproof has become a leading supplier for global contractors and engineering projects.

What Is Seamless Polyurethane Waterproofing Coating?

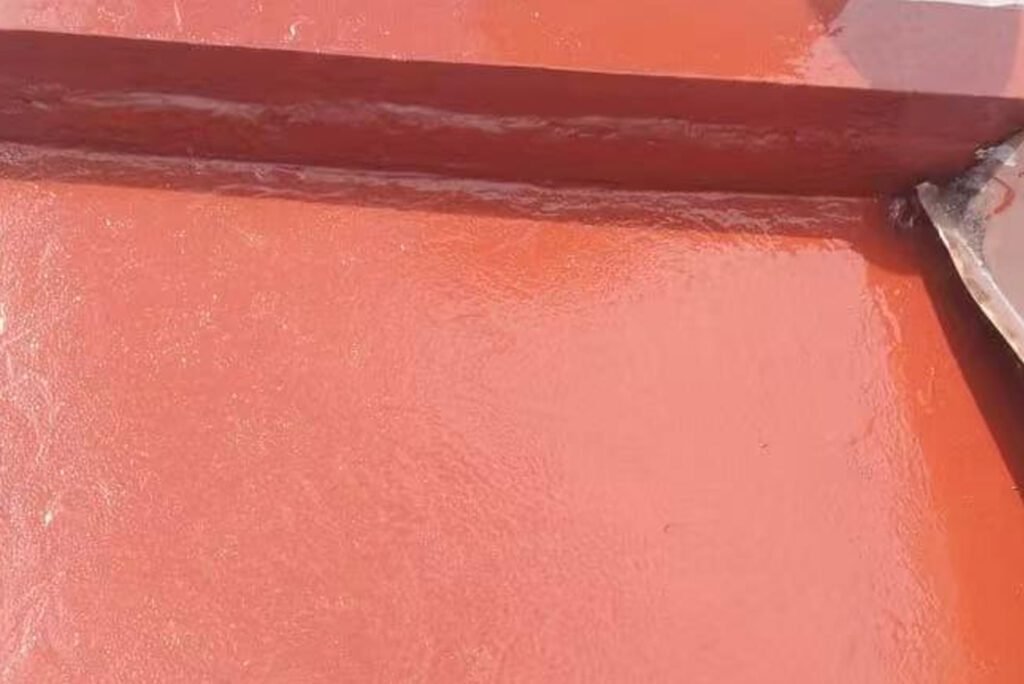

Polyurethane waterproofing is a liquid-applied membrane composed primarily of high-performance polyurethane resins. Once applied, it undergoes a chemical curing process that transforms the liquid coating into a seamless, elastic, and durable film tightly bonded to the substrate.

Unlike sheet-based waterproofing materials, polyurethane coatings eliminate joints and overlaps, which are the most common sources of leakage.

Key technical characteristics include:

- Chemical curing creates a fully bonded, joint-free membrane.

- High elasticity (elongation > 300%) to withstand building movements.

- Excellent adhesion to concrete, metal, and various substrates.

- Long-lasting flexibility and UV resistance.

- Compatibility with green building standards (low-VOC formulations).

This technology provides a new generation of waterproof protection designed specifically for concrete structures that demand high strength and reliability.

Why Concrete Structures Need Seamless Waterproofing Systems?

Concrete is a strong and versatile building material—but inherently porous and micro-cracked. These characteristics make it susceptible to:

- Water infiltration through capillaries and cracks

- Structural degradation from freeze-thaw cycles

- Rebar corrosion due to moisture penetration

- Chemical attack from salts and acidic solutions

Traditional waterproofing systems, such as bitumen membranes or cementitious coatings, often fail at joints or overlaps, leading to leakage over time.

Seamless polyurethane waterproofing coatings overcome these limitations by forming a continuous, flexible, and watertight membrane directly bonded to the concrete surface.

This provides several advantages:

- Zero joint failures or seam gaps.

- Adapts to thermal and structural movements.

- Long-term resistance to hydrostatic pressure.

- Enhanced protection for structural concrete integrity.

By integrating this technology, construction professionals can extend building lifespan, minimize maintenance, and ensure long-term structural safety.

Key Performance Advantages of Seamless Polyurethane Waterproofing

Polyurethane coatings stand out in modern engineering due to their combination of flexibility, toughness, and chemical stability. Below are the main benefits that make it superior to other systems:

High Elasticity & Crack Bridging

Can stretch over 300% without cracking, ideal for dynamic structures such as bridges, parking decks, and basements.

Seamless and Fully Bonded System

Eliminates weak points caused by laps, welds, or seams. Once cured, it becomes an integral part of the concrete surface.

Exceptional Adhesion Strength

Bonds tightly to concrete, metal, stone, and other substrates, even on complex geometries or vertical surfaces.

Excellent Weather and UV Resistance

Suitable for outdoor exposure, maintaining integrity under sunlight, rain, or temperature changes.

Chemical and Corrosion Resistance

Performs reliably in industrial environments exposed to oils, acids, or salts.

Low VOC and Eco-Friendly Formulations

YURU’s polyurethane coatings are formulated with low or zero solvents, making them compliant with green building certifications.

These features make it one of the most advanced and sustainable waterproofing technologies for concrete structures today.

Typical Applications of Seamless Polyurethane Waterproofing Coatings

Because of its high adaptability and excellent adhesion, seamless polyurethane waterproofing is used in a wide range of construction and infrastructure projects, including:

Roofs and Terraces

Provides a durable, flexible membrane that resists water ponding and UV exposure, ideal for both flat and sloped roofs.

Basements and Foundations

Withstands constant hydrostatic pressure, protecting concrete from long-term water seepage and corrosion.

Concrete Floors and Parking Decks

Enhances durability and abrasion resistance while serving as a waterproof underlayer for epoxy or PU flooring systems.

Tunnels, Bridges, and Metro Systems

Ensures waterproof integrity in high-moisture and vibration-prone environments.

Water Tanks and Reservoirs

Safe for contact with potable water due to its non-toxic, solvent-free formulation.

Green Roofs and Landscaping

Combines waterproofing and root barrier functions, ensuring sustainable design compatibility.

Each application highlights the versatility and technical superiority of polyurethane waterproofing in protecting modern infrastructure.

Application Process and Technical Guidelines

Proper application is essential for achieving long-term waterproofing performance. Below is the standard procedure recommended by YURU Waterproof technical experts:

1. Surface Preparation

- Remove dust, oil, and loose materials.

- Repair cracks and voids with YURU polyurethane crack filler.

2. Waterproofing Layer

- Apply in 2–3 coats using roller, brush, or airless spray.

- Total dry film thickness: 1.5–2.0 mm (based on project requirements).

3. Detail Reinforcement

Strengthen corners, pipe junctions, and edges using reinforcing fabric embedded into the wet coating.

4. Curing & Inspection

Allow curing for 24–48 hours at 25°C before conducting a water ponding or flood test.

5. Optional Topcoat

For exposed applications, apply a UV-resistant polyurethane topcoat for additional protection.

By following these steps, contractors can achieve maximum waterproof integrity, surface uniformity, and system longevity.

FAQs

- What makes seamless polyurethane waterproofing different from traditional coatings?

It forms a continuous membrane with no seams or overlaps, eliminating the most common leakage points found in traditional materials.

- Can polyurethane waterproofing be applied on damp concrete?

Yes. YURU’s water-based polyurethane systems allow application on slightly damp substrates, improving construction flexibility.

- How long does polyurethane waterproofing last?

With proper installation, it lasts over 20 years, maintaining elasticity and adhesion even under UV and thermal stress.

- Is it environmentally safe?

Yes. YURU formulations are low-VOC, solvent-free, and compliant with global environmental standards such as ISO and RoHS.

- Does YURU Waterproof offer project-specific customization?

Absolutely. We provide OEM and bulk production services customized to local climates and project requirements.

Conclusion

Seamless polyurethane waterproofing coatings represent the future of concrete protection — offering unmatched durability, elasticity, and environmental safety.

For contractors, wholesalers, and engineering project managers, choosing YURU Waterproof means:

- Reliable product quality.

- Proven technical expertise.

- Sustainable and cost-effective waterproofing solutions.

Build stronger. Build greener. Build smarter — with YURU Waterproof.

YURU Product solutions

Waterproof Coating

- One-component oil-based polyurethane waterproof coating

- One-component water-based polyurethane waterproof coating

- Two-component polyurethane waterproof coating

- Two-component 6.0Mpa polyurethane waterproof coating

- Transparent Waterproof Glue

- Nano Invisible Waterproof Agent

- Silicone Waterproof Coating

- Acrylic Waterproof Coating For Metal Roof

- JS Polymer Waterproof Coating

- High Elastic Liquid Rubber Waterproof Coating

- Cement-based Penetrating Crystallization Waterproof Coating