Best Polyurethane Waterproof Coating for Roof Waterproofing Contractors

Introduction

Modern construction projects demand long-lasting and efficient waterproofing systems — especially for concrete and flat roofs, which are constantly exposed to rain, UV rays, and temperature changes. Among the various waterproofing materials available today, polyurethane waterproof coating has become the preferred choice for professional roof waterproofing contractors.

Its seamless application, superior elasticity, and high adhesion make it one of the most dependable solutions in the roofing industry. This article explores the advantages, technical features, application process, and YURU Waterproof’s polyurethane coating systems, designed specifically for roofing contractors and large-scale construction projects.

The Importance of Polyurethane Coatings in Roof Waterproofing

Concrete roofs, while durable, are naturally porous. Over time, small cracks and surface imperfections allow water to penetrate, causing corrosion, leaks, and even structural damage. For roof waterproofing contractors, preventing these issues requires materials that combine flexibility, chemical resistance, and strong substrate bonding.

Polyurethane waterproof coatings meet all these requirements. As a liquid-applied waterproofing membrane, they create a monolithic (seamless) layer that fully adheres to the substrate, forming a durable, watertight shield against moisture and weather exposure.

Why Contractors Prefer Polyurethane Systems:

- Simple, joint-free installation compared to traditional membranes.

- Strong adhesion to concrete, metal, and asphalt surfaces.

- Excellent crack-bridging ability to accommodate structural movement.

- High UV and thermal resistance for exposed roofs.

- Proven long-term durability and easy maintenance.

These benefits make polyurethane coatings ideal for contractors working on commercial buildings, industrial roofs, and infrastructure projects where reliability is essential.

Core Performance Advantages of Polyurethane Waterproof Coatings

Polyurethane coatings are engineered with advanced polymer chemistry that delivers a unique balance between strength and flexibility. Below are their key technical advantages:

1. Seamless Membrane Protection

Unlike roll-based materials with joints, polyurethane forms a continuous, joint-free film that eliminates leakage paths.

2. High Elasticity and Crack-Bridging Ability

Elongation rates of up to 300% allow the coating to stretch with structural movements, preventing cracking under stress.

3. UV and Weather Resistance

High-quality PU coatings resist degradation under intense UV radiation, temperature variations, and heavy rainfall — perfect for exposed roof applications.

4. Excellent Adhesion and Chemical Resistance

They adhere tightly to a variety of substrates and resist alkalis, mild acids, and atmospheric pollutants.

5. Eco-Friendly Options

Water-based and low-VOC formulations reduce environmental impact and comply with modern green building standards.

6. Long-Term Cost Efficiency

Although initial material costs may be higher, polyurethane coatings significantly lower lifecycle costs due to extended service life (15–25 years) and minimal maintenance.

These characteristics explain why polyurethane coatings are considered the new standard in professional roofing waterproofing systems.

Installation Process and Technical Guidelines

For roof waterproofing contractors, understanding the correct installation process is essential for achieving consistent, high-performance results.

Here’s a professional guide based on YURU Waterproof’s recommended practices:

Surface Preparation:

Clean and dry the substrate thoroughly. Remove dust, oil, and loose materials. Repair any cracks or voids.

Priming:(It depends on the situation)

Apply a polyurethane-compatible primer to enhance bonding strength. Allow it to dry before applying the main coating.

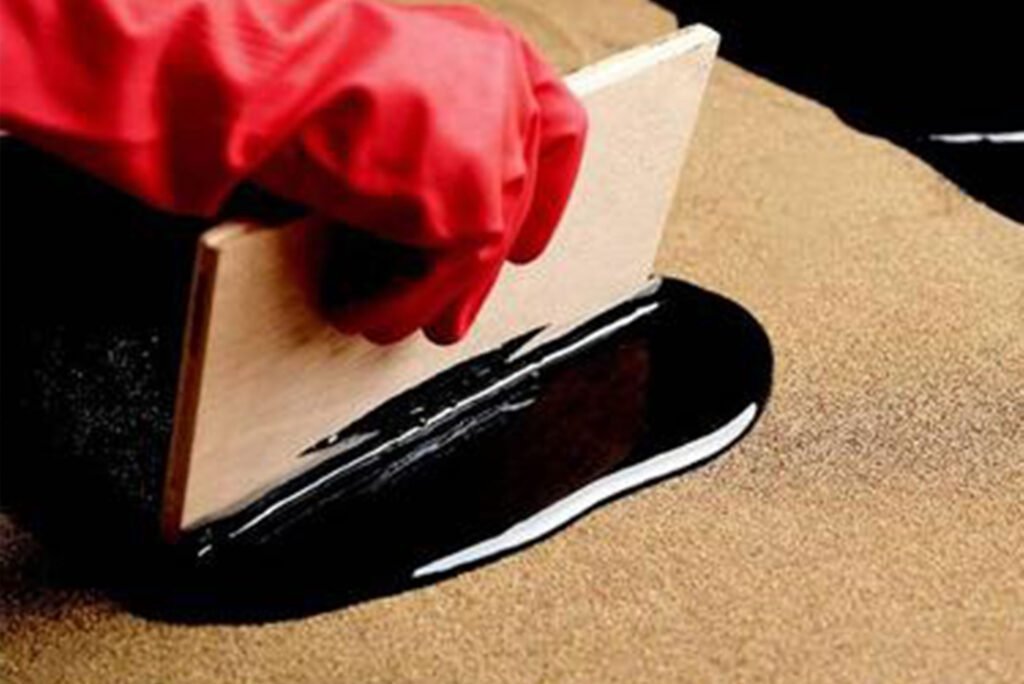

Main Coating Application:

Apply the polyurethane coating in multiple layers using a roller, brush, or airless spray machine. Maintain the specified film thickness (typically 1.5–2.0 mm dry film).

Reinforcement at Critical Areas:

Apply additional coating or reinforcing fabric at corners, pipe penetrations, and joints.

Curing and Protection:

Allow sufficient curing time (24–48 hours). For exposed roofs, use a UV-resistant topcoat to enhance color stability.

Quality Testing:

Conduct adhesion and ponding tests before final acceptance.

This simple yet effective process makes polyurethane coatings easy to apply, time-efficient, and suitable for both small-scale and large roofing projects.

Types of Polyurethane Coatings and Application Scenarios

Polyurethane waterproof coatings come in several formulations, each designed for specific roof types, climates, and performance requirements.

1. Single-Component Solvent-Based Polyurethane Coating

- Excellent for outdoor applications and complex roof structures.

- Creates a dense, durable waterproof film.

- Resistant to UV exposure and extreme weather conditions.

2. Single-Component Water-Based Polyurethane Coating

- Eco-friendly, low-VOC, and odorless.

- Suitable for indoor roofs and green building projects.

- Fast-drying and easy to clean after application.

3. Two-Component Polyurethane Coating (A+B System)

- Chemical curing reaction creates a high-strength, high-adhesion waterproof membrane.

- Offers excellent resistance to hydrostatic pressure.

- Recommended for large commercial and industrial roofs.

4. High-Standard Polyurethane Coating for Railway and Bridge Decks

- Designed for high-load structures and vibration-prone environments.

- Outstanding fatigue resistance and durability.

- Ideal for railway infrastructure and heavy-duty roof systems.

Each product type serves distinct engineering needs — from residential rooftops to complex industrial and transportation projects — making polyurethane coatings a versatile choice for professional contractors.

Polyurethane VS Traditional Waterproofing Materials

| Property | Polyurethane Coating | SBS Bitumen Membrane | Cementitious Coating | Acrylic Coating |

|---|---|---|---|---|

| Seams | Seamless, monolithic | Many overlap joints | Minimal joints | Seamless |

| Elasticity | Excellent | Moderate | Poor | Moderate |

| UV Resistance | High | Medium | Low | Good |

| Durability | 15–25 years | 5–8 years | 3–5 years | 6–8 years |

| Installation | Liquid-applied | Heat torch required | Manual brush | Roller |

| Maintenance | Easy recoat | Difficult | Frequent | Occasional |

| Environmental Safety | Low VOC options | Contains bitumen | Safe | Safe |

This comparison highlights that polyurethane coatings deliver the best combination of long service life, flexibility, and environmental safety — critical factors for professional roofing contractors seeking durable and efficient solutions.

YURU Waterproof Polyurethane Product Systems

YURU Waterproof offers a comprehensive range of polyurethane waterproof coatings engineered for diverse roofing applications. Each product undergoes strict quality testing and complies with international standards such as ISO, CE, and others.

YURU Product Line:

1. Single-Component Oil-Based PU Coating

- Designed for outdoor roofs and complex details.

- Excellent adhesion and weather resistance.

- Easy to apply and maintain.

2. Single-Component Water-Based PU Coating

- Eco-friendly and low odor.

- Quick drying and ideal for sustainable construction.

- Perfect for indoor roofs and enclosed environments.

3. Two-Component PU Waterproof Coating

- A/B reaction system forming a robust waterproof film.

- Superior tensile strength and hydrostatic pressure resistance.

- Ideal for commercial and large-scale roofing systems.

4. High-Standard PU Coating for Railways & Bridges

- Engineered for heavy load-bearing structures.

- Exceptional abrasion resistance and adhesion stability.

- Meets high-performance requirements for infrastructure waterproofing.

All YURU products are manufactured under strict ISO 9001 and ISO 14001 systems and supported by expert technical assistance. YURU Waterproof also provides OEM/ODM customization and wholesale supply for global contractors and distributors.

Why Roof Waterproofing Contractors Choose YURU Waterproof?

Roofing contractors worldwide rely on YURU Waterproof for its technical reliability, material quality, and service consistency.

Key Advantages:

- 20+ years of polyurethane technology and application experience.

- In-house R&D and quality control laboratories.

- Competitive wholesale pricing and bulk customization.

- Global distribution network covering Asia, the Middle East, and Europe.

- Comprehensive technical training and after-sales support.

Choosing YURU Waterproof means partnering with a trusted manufacturer dedicated to performance, precision, and long-term protection for every roofing project.

Conclusion

Polyurethane waterproof coatings have revolutionized the roofing industry, providing contractors with a long-lasting, flexible, and seamless solution for protecting concrete roofs. Their superior performance, durability, and adaptability make them indispensable for modern construction projects.

YURU Waterproof continues to innovate in polyurethane technology, delivering certified, high-quality materials that meet the toughest project requirements. Whether you are a contractor, wholesaler, or engineering project manager, YURU’s polyurethane coatings guarantee performance you can trust.

YURU Waterproof – Your Reliable Partner for Professional Roof Waterproofing Solutions.

Looking for a dependable polyurethane waterproof coating supplier for your roofing projects?

Contact YURU Waterproof for expert guidance, wholesale pricing, and technical consultation.

FAQs

- Why is polyurethane coating better than bitumen or cementitious waterproofing?

Because it forms a seamless, highly elastic film with longer durability and lower maintenance costs.

- How long does polyurethane waterproof coating last on roofs?

A quality polyurethane system typically lasts 15 to 25 years, depending on the environment and coating thickness.

- Can YURU coatings be used for both flat and sloped roofs?

Yes. They have excellent adhesion and flow control, suitable for various roof structures.

- Do YURU products comply with environmental standards?

Absolutely. YURU offers both low-VOC solvent-based and water-based polyurethane coatings certified for eco-friendly construction.

- Does YURU provide technical training or project guidance?

Yes. YURU Waterproof provides training, product selection advice, and technical documentation for contractors.

YURU Product solutions

Waterproof Coating

- One-component oil-based polyurethane waterproof coating

- One-component water-based polyurethane waterproof coating

- Two-component polyurethane waterproof coating

- Two-component 6.0Mpa polyurethane waterproof coating

- Transparent Waterproof Glue

- Nano Invisible Waterproof Agent

- Silicone Waterproof Coating

- Acrylic Waterproof Coating For Metal Roof

- JS Polymer Waterproof Coating

- High Elastic Liquid Rubber Waterproof Coating

- Cement-based Penetrating Crystallization Waterproof Coating