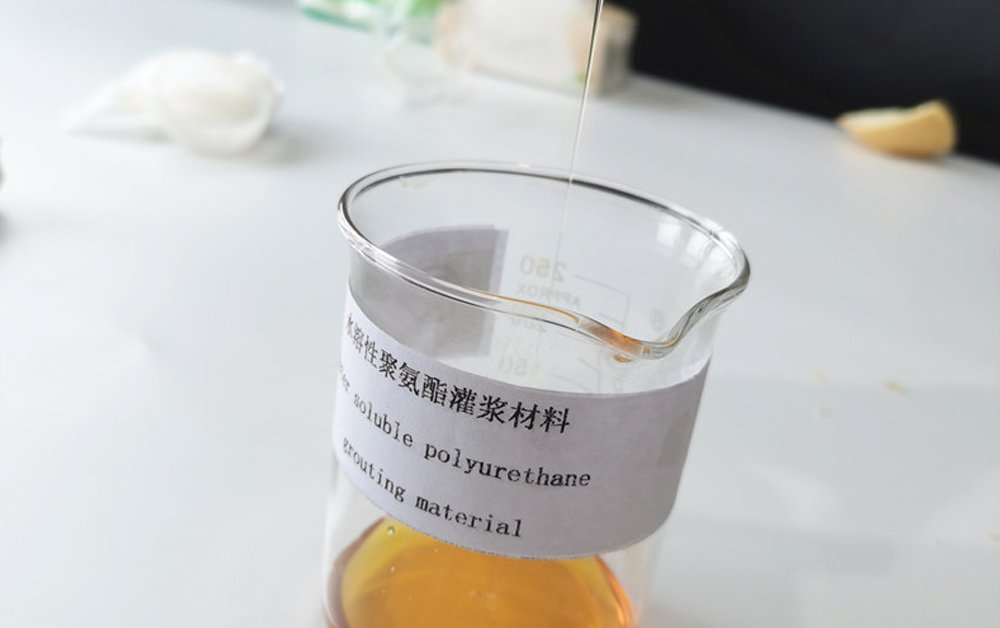

Eco-Friendly Hydrophilic Polyurethane Grouting Solutions

Introduction — The Rise of Eco-Friendly Grouting Technologies

In the modern construction industry, sustainability and environmental responsibility are no longer optional—they are essential. Governments, developers, and contractors are increasingly prioritizing green materials and low-VOC solutions that align with global sustainability standards.

Among various waterproofing and repair systems, eco-friendly hydrophilic polyurethane grouting has emerged as a reliable and sustainable technology for sealing leaks, stabilizing structures, and extending the lifespan of concrete infrastructure.

Unlike traditional solvent-based systems that often contain harmful volatile organic compounds (VOCs), water-based hydrophilic polyurethane grouting materials offer a safer, low-emission alternative. These systems are particularly effective in tunnels, subways, basements, parking structures, and water reservoirs, where moisture exposure and environmental compliance are both critical.

With its balance of environmental safety and high performance, hydrophilic polyurethane grouting is becoming the preferred solution for contractors, engineers, and material distributors looking to meet green building certification standards while ensuring long-term waterproofing reliability.

Understanding Hydrophilic Polyurethane Grouting — How It Works

Hydrophilic polyurethane grouting materials are based on reactive polymers that form flexible, water-absorbing gels or foams when they come into contact with moisture. Unlike traditional hydrophobic systems that repel water, hydrophilic formulations are designed to absorb and react with water, allowing them to expand, penetrate fine cracks, and create a watertight seal.

Chemical and Functional Principles

When injected into a leaking or damp concrete substrate, hydrophilic polyurethane resin reacts with the surrounding water to create a semi-flexible, open-cell foam. This foam expands volumetrically, filling voids and microcracks to form a permanent waterproof barrier.

The chemical reaction typically involves:

- Polyurethane prepolymer reacting with water to release CO₂ gas.

- Expansion and curing into an elastic waterproof mass.

- Strong adhesion to concrete, rock, and steel surfaces.

Key Technical Advantages:

- High flexibility and elongation after curing, allowing it to withstand structural movements.

- Excellent adhesion to wet surfaces, including concrete and rock.

- Adjustable curing speed, allowing precise control for different site conditions.

- Low viscosity, ensuring deep penetration into fine cracks.

- Non-toxic and solvent-free, making it ideal for confined or sensitive environments.

In short, hydrophilic polyurethane grouting combines superior sealing efficiency with environmental safety, offering an advanced alternative to traditional chemical grouts.

Environmental Benefits of Hydrophilic Polyurethane Grouting

Sustainability is a growing priority in infrastructure development, and water-based polyurethane grouting materials contribute significantly to achieving environmental compliance and worker safety.

1. Low VOC and Odor-Free Formulation

Hydrophilic polyurethane grouting is formulated without organic solvents, making it virtually free of volatile organic compounds (VOCs). This reduces on-site air pollution and ensures compliance with global environmental standards such as RoHs, and ISO 14001.

2. Safe and Non-Flammable

Unlike solvent-based grouts that can pose fire or inhalation risks, water-based systems are non-flammable, non-toxic, and safe for indoor and underground use—ideal for tunnels, basements, and wastewater facilities.

3. Reduced Carbon Footprint

Because these systems use water as a reactive component, they minimize the need for hazardous solvents and reduce the carbon footprint associated with chemical manufacturing and transportation.

4. Sustainable Construction Compliance

Many modern construction projects require the use of materials that support green building certifications. YURU Waterproof’s hydrophilic polyurethane systems are designed to meet the criteria of environmentally responsible construction, ensuring both ecological safety and long-term durability.

Technical Performance and Application Advantages

Beyond its environmental profile, hydrophilic polyurethane grouting provides excellent mechanical and chemical performance in demanding construction environments.

Key Technical Properties

- Penetration Ability: Capable of filling cracks as small as 0.1 mm due to its low viscosity.

- Controlled Expansion: Foam expansion ratios can reach up to 20 times the original volume, ensuring complete crack filling.

- Elastic Recovery: Maintains flexibility even after repeated wet/dry cycles.

- High Bond Strength: Chemically bonds with concrete substrates to form a watertight seal.

- Durability: Resistant to aging, freeze-thaw cycles, and mild chemical exposure.

Typical Applications

- Tunnels and subways with continuous water ingress.

- Underground parking garages and basements with hydrostatic pressure.

- Water treatment plants and reservoirs requiring long-term sealing.

- Structural crack repair in retaining walls and bridge abutments.

This combination of eco-friendly chemistry and engineering-grade performance makes hydrophilic polyurethane grouting a trusted solution for both new construction and rehabilitation projects.

Applications in Modern Construction and Infrastructure Projects

Hydrophilic polyurethane grouting systems have proven to be versatile in various civil, industrial, and municipal engineering projects. Their ability to adapt to wet conditions and complex substrates makes them ideal for:

1. Underground Infrastructure

Used in tunnels, subways, and shafts to control active water leakage and prevent structural deterioration.

2. Basements and Underground Parking Structures

Ensures long-term waterproofing protection against hydrostatic pressure and groundwater seepage.

3. Water Management Systems

Ideal for reservoirs, dams, and wastewater treatment plants, where constant water exposure demands reliable sealing performance.

4. Structural Crack Repair

Fills and seals cracks in concrete beams, columns, and retaining walls without disrupting the structural integrity.

5. Soil and Rock Grouting

Enhances stability in foundation engineering by sealing porous or fractured rock formations.

By reducing water infiltration and reinforcing the substrate, hydrophilic polyurethane grouting contributes directly to structural safety and environmental protection.

YURU Waterproof’s Sustainable Grouting Solutions

As a global provider of advanced waterproofing and injection materials, YURU Waterproof offers a complete range of polyurethane grouting systems tailored to diverse construction needs.

YURU’s Grouting Material Portfolio:

- Water-Based Hydrophilic Polyurethane Grouting Materials – Environmentally friendly, ideal for wet crack sealing and leak repair.

- Oil-Based Hydrophobic Polyurethane Grouting Materials – Durable and dense, suitable for dry or low-moisture structures.

- Acrylate Grouting Materials – Ultra-low viscosity for fine crack penetration and soil curtain grouting.

- Epoxy Resin Grouting Systems – High-strength bonding for structural reinforcement.

- Polyurea Grouting Materials – Rapid-curing systems with superior chemical resistance.

- Microcrystalline Polyurea Grouting Materials – Enhanced durability for tunnels, bridges, and high-pressure sealing.

All YURU Waterproof materials are tested and certified according to ISO standards, ensuring consistent quality and performance across projects.

YURU also provides:

- OEM/ODM formulation customization

- Project-based technical consultation

- Application support and training

YURU Waterproof — Delivering Sustainable Polyurethane Grouting Solutions for a Greener Future in Construction.

FAQs

- What makes hydrophilic polyurethane grouting eco-friendly?

It is water-based, solvent-free, and low in VOC emissions, minimizing health and environmental risks during and after application.

- Can it be used in active water leakage conditions?

Yes. Hydrophilic polyurethane reacts with water, making it ideal for active leaks and damp concrete substrates.

- How long does the cured foam last?

When properly applied, the cured material can last 15–25 years while maintaining elasticity and adhesion.

- What industries use YURU Waterproof’s grouting materials?

Our materials are used in tunnels, dams, basements, bridges, subways, and wastewater systems worldwide.

- Does YURU offer technical support and customized solutions?

Yes. YURU Waterproof provides OEM/ODM services, formulation customization, and technical consultation for different project conditions.

Conclusion

Eco-friendly hydrophilic polyurethane grouting is redefining waterproofing standards in modern infrastructure by combining sustainability, performance, and durability. Its ability to form flexible waterproof barriers in moist environments—without harmful solvents or emissions—makes it the preferred choice for green construction projects worldwide.

Through continuous innovation and technical excellence, YURU Waterproof provides advanced polyurethane grouting solutions that align with global environmental goals while ensuring structural integrity and long-term protection.

For technical consultation, OEM partnerships, or bulk supply inquiries, visit www.yuruwaterproof.com or contact our engineering team today.

YURU Product solutions

Waterproof Coating

- One-component oil-based polyurethane waterproof coating

- One-component water-based polyurethane waterproof coating

- Two-component polyurethane waterproof coating

- Two-component 6.0Mpa polyurethane waterproof coating

- Transparent Waterproof Glue

- Nano Invisible Waterproof Agent

- Silicone Waterproof Coating

- Acrylic Waterproof Coating For Metal Roof

- JS Polymer Waterproof Coating

- High Elastic Liquid Rubber Waterproof Coating

- Cement-based Penetrating Crystallization Waterproof Coating