What Weather Conditions Are Required for Applying Polyurethane Coatings?

Polyurethane waterproof coatings are widely used in roofing, basements, industrial floors, exterior walls, metal sheets, and large engineering projects. They are known for strong adhesion, excellent elasticity, and long-term waterproofing durability. However, one crucial factor that determines whether polyurethane waterproofing succeeds or fails is weather conditions during application.

Contractors, waterproofing specialists, and engineering project managers often ask:

“What weather conditions are required for applying polyurethane coatings?”

This comprehensive guide covers everything from temperature and humidity to wind speed, surface moisture, rainfall conditions, and differences between oil-based and water-based polyurethane systems.

Why Weather Conditions Matter When Applying Polyurethane Coatings?

Polyurethane waterproofing relies on chemical curing, forming a seamless, elastic waterproof membrane through a controlled reaction between its components. Because it is not a simple “drying paint,” environmental factors significantly influence its performance.

Key reasons weather conditions matter:

- Temperature affects curing speed and chemical reaction stability

- Humidity influences film formation and bond strength

- Surface moisture may cause bubbling, whitening, or adhesion failure

- Wind can impact solvent evaporation and introduce dust contamination

- Rain or fog disrupts the coating before it cures

- Extreme heat or cold can permanently damage the membrane

Consequences of poor weather during application

- Delayed or incomplete curing

- Weak adhesion and peeling

- Soft or sticky coating surface

- Surface bubbling from trapped moisture

- Cracking due to rapid reaction in high heat

- Washed-off coating during rain

Because polyurethane requires controlled environmental conditions, contractors must follow weather guidelines strictly to ensure durable waterproofing results.

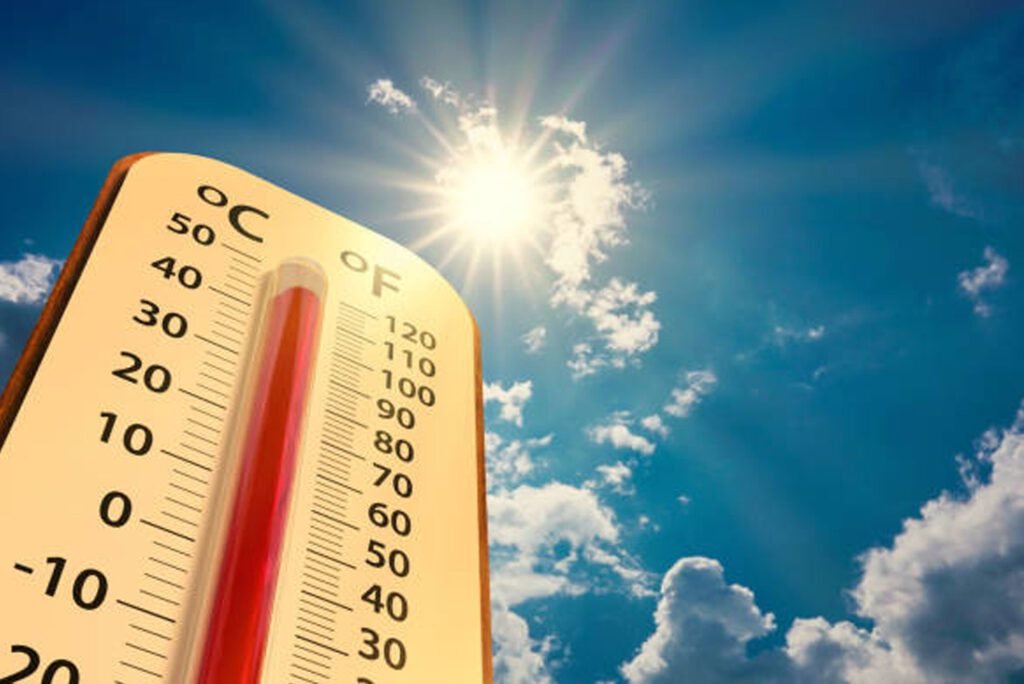

Recommended Temperature Range for Polyurethane Application

Temperature is one of the most critical factors affecting polyurethane’s curing and bonding performance.

Ideal temperature range

Most polyurethane waterproof coatings should be applied within:

5°C to 35°C (41°F to 95°F)

Low temperatures (<5°C) cause:

- Extremely slow curing

- Poor adhesion to the substrate

- Internal moisture condensation

- Soft or tacky surface even after many hours

- Increased risk of blistering

At very low temperatures, the chemical reaction nearly stops, preventing proper film formation.

High temperatures (>35°C) cause:

- Rapid curing, leading to uneven membrane formation

- Surface bubbles as solvents evaporate too quickly

- Loss of elasticity

- Cracking due to overheating

- Flow marks caused by rapid surface drying

Important note:

Substrate temperature may differ from air temperature by 5–10°C, especially on metal roofs exposed to direct sunlight. Always measure both before starting work.

Impact of Humidity and Substrate Moisture Levels

Humidity affects both polyurethane curing and substrate bonding.

Maximum recommended humidity

Relative Humidity (RH) should be ≤ 85%.

High humidity can cause:

- Whitening or “blushing” on the coating surface

- Slower curing speed

- Bubbles from trapped moisture

- Surface tackiness due to incomplete drying

- Poor adhesion between layers

Substrate moisture level requirements

- Oil-based polyurethane requires a dry substrate

- Water-based polyurethane can tolerate slightly damp surfaces

Excess moisture on substrate surfaces leads to:

- Internal blistering

- Pinholes

- Reduced adhesion strength

- Coating separation

Recommended surface moisture detection methods

- Moisture meter

- Plastic sheet test (taping a polyethylene sheet and checking condensation)

Rainwater influence

After rain, substrates must be air-dried before coating. Depending on the climate, drying time can range from 2–48 hours.

Wind Speed and Ventilation Requirements (Especially for Solvent-Based Systems)

Wind speed affects drying behavior, coating uniformity, and even worker safety.

Recommended wind conditions:

- Outdoor wind speed <5 m/s

- Indoor ventilation must be sufficient but controlled

High wind speeds create problems:

- Rapid surface drying leading to skin formation

- Uneven thickness caused by wind-driven flow

- Dust and debris contamination

- Increased solvent evaporation rate

- Reduced bonding if the substrate surface cools too quickly

For solvent-based polyurethane

Ventilation is essential to prevent VOC accumulation, but strong airflow must be avoided to ensure uniform curing.

Weather Conditions to Avoid: Rain, Snow, Fog, and Extreme Sun Exposure

Certain weather conditions make polyurethane application risky or completely unacceptable.

Do NOT apply polyurethane during:

- Rain

- Snow

- Frost or freezing conditions

- Heavy fog

- Dew formation

- High UV exposure

- Surface condensation

Reasons these conditions cause failure:

- Rain washes away uncured coating

- Fog and dew introduce moisture into the membrane

- Frost prevents chemical reaction

- Direct sunlight accelerates curing too quickly

- Snow and ice prevent film adhesion

- Wet substrates trap moisture, causing future blistering

Contractor guideline:

If rain is expected within 4–6 hours, application should be postponed.

Weather-Related Differences Between Oil-Based and Water-Based Polyurethane Coatings

Oil-Based Polyurethane

- Strong bonding

- High chemical resistance

- Good mechanical strength

× Cannot be directly exposed outdoors

× Requires topcoat protection (acrylic, polyurea, or PU topcoat)

Suitable for:

- Metal substrates

- Interior concrete

- Industrial floors

- Waterproofing under protective screeds

Water-Based Polyurethane

- UV resistance

- Can be used as exposed waterproofing

- Suitable for slightly damp substrates

- Low odor and low VOC

- Better elasticity

Ideal for:

- Exposed roofs

- Balconies

- Exterior walls

- Bathrooms and wet areas

- Fast project turnaround

Weather flexibility comparison

| Performance | Oil-based PU | Water-based PU |

|---|---|---|

| UV resistance | Low | Excellent |

| Exposed use | No | Yes |

| Moisture tolerance | Low | Medium |

| Ideal climate | Dry, mild | Wide climate range |

| Indoor/Outdoor | Mainly indoor | Indoor & outdoor |

Contractors should choose the polyurethane type based on weather conditions, substrate type, and project location.

How Contractors Should Plan Projects Based on Weather Conditions?

Project scheduling is essential for large-scale waterproofing work.

Pre-work preparation

- Check weather forecast for at least 48–72 hours.

- Measure substrate moisture and temperature.

- Prepare shelter materials (tarps, covers, wind barriers).

- Conduct adhesion tests on-site when weather changes rapidly.

Seasonal recommendations

Rainy Season

- Work only during stable dry windows.

- Plan coating tasks in the morning to avoid afternoon humidity.

- Store materials indoors to prevent moisture contamination.

Summer

- Avoid direct sunlight during mid-day.

- Apply coatings early morning or late afternoon.

- Ensure workers hydrate and avoid heat risks.

Winter

- Ensure temperature stays above 5°C.

- Avoid early morning dew.

- Use heaters for interior spaces if needed.

Communication with clients

Contractors should explain weather-dependent curing behaviors to ensure realistic timelines—especially for outdoor projects like roofs and balconies.

Weather-related delays are normal and necessary to guarantee a long-lasting waterproofing result.

Why Choose YURU Waterproof Polyurethane Coatings for Your Projects?

YURU Waterproof is a trusted manufacturer specializing in polyurethane waterproof coatings, injection materials, and floor-coating systems for professional contractors and bulk buyers.

Our advantages

- Complete range of oil-based and water-based polyurethane coatings

- Stable curing performance under a wide range of weather conditions

- High bonding strength across concrete, metal, tile, PVC, and more

- OEM and private-label customization

- Bulk pricing for wholesalers and engineering firms

- Technical support for on-site application

- Export-grade packaging and strong logistics capability

YURU Waterproof helps contractors achieve reliable waterproofing results, even in challenging climate environments.

FAQs:

1. Can polyurethane waterproofing be applied in cold weather?

Yes, but temperatures must remain above 5°C. Below this, curing stops and adhesion fails.

2. How long after rainfall should I wait before applying polyurethane?

Typically between 2–48 hours, depending on substrate drying conditions.

3. Can polyurethane be applied during high humidity?

Humidity must be below 85%. High humidity causes whitening and blistering.

4. Can water-based polyurethane be applied to slightly damp substrates?

Yes. Water-based polyurethane tolerates slight moisture, unlike oil-based systems.

5. What happens if polyurethane is applied in strong sunlight?

It will cure too quickly, causing shrinkage cracks and surface defects.

6. Is wind a problem during polyurethane coating application?

Strong wind (>5 m/s) is not recommended, as it causes uneven curing and contamination.

YURU Product solutions

Waterproof Coating

- One-component oil-based polyurethane waterproof coating

- One-component water-based polyurethane waterproof coating

- Two-component polyurethane waterproof coating

- Two-component 6.0Mpa polyurethane waterproof coating

- Transparent Waterproof Glue

- Nano Invisible Waterproof Agent

- Silicone Waterproof Coating

- Acrylic Waterproof Coating For Metal Roof

- JS Polymer Waterproof Coating

- High Elastic Liquid Rubber Waterproof Coating

- Cement-based Penetrating Crystallization Waterproof Coating