Can Acrylic Waterproof Coatings Be Applied on Damp Concrete Substrates?

How to Choose the Best Polyurea Coating Material for Your Construction Project

Acrylic waterproof coatings are widely used in roofing, wall protection, basements, balconies, and general building waterproofing. However, one of the most common questions from contractors and project managers is whether acrylic waterproof coatings can be applied on damp concrete substrates.

This is an important question because moisture levels in concrete significantly impact adhesion, polymer film formation, long-term durability, and the stability of the waterproofing system. In real construction environments, concrete is rarely perfectly dry—especially in humid climates, newly cast surfaces, underground structures, rainy seasons, or areas with inadequate sunlight.

This article provides a comprehensive, engineering-grade guide on whether acrylic coatings can be applied to damp concrete, how to evaluate substrate moisture, the risks involved, the construction requirements, and how to ensure stable adhesion and film formation.

1. Can Acrylic Waterproof Coatings Be Applied on Damp Concrete?

Acrylic waterproof coatings are water-based, meaning they are inherently more tolerant of moisture compared to solvent-based or polyurethane waterproofing systems. Because acrylic coatings cure through water evaporation and polymer particle coalescence, they can generally be applied to slightly damp concrete, provided:

- There is no standing water.

- Moisture is not actively seeping or leaking.

- The substrate is saturated-surface-dry (SSD).

- The layer is not applied excessively thick at once.

- Environmental humidity allows gradual drying.

In many engineering projects, especially during humid seasons or on newly cast concrete, achieving a fully dry substrate is difficult. This is where acrylic waterproof coatings show a major advantage—they can work effectively even when the concrete still contains mild residual moisture.

When Acrylic Coatings Are Suitable for Damp Concrete:

- Concrete looks dark from moisture but has no visible water film.

- Substrate feels cool and slightly damp to the touch.

- Moisture comes from recent cleaning or early-stage drying.

- The air environment allows ongoing evaporation.

When Acrylic Coatings Should NOT Be Applied:

- Visible water droplets remain on the surface.

- Water is actively leaking or seeping.

- The substrate is saturated to the point of dripping.

- Moisture comes from a structural issue or active water ingress.

In short, acrylic waterproof coatings can be applied to damp—but not wet or leaking—concrete. Understanding this difference helps contractors avoid common waterproofing failures such as blistering, whitening, and adhesion loss.

2. Key Risks of Applying Acrylic Coatings on Damp Concrete

Although acrylic coatings tolerate mild moisture, there are still risks when moisture levels are too high. Contractors must understand these risks before proceeding with construction.

2.1 Risk of Reduced Adhesion

Excess moisture can prevent the acrylic polymer from bonding fully with the substrate. When the concrete keeps releasing moisture during curing, the coating might weaken or detach. Adhesion issues often appear in:

- Low-ventilation indoor spaces

- Basement walls

- Wet foundations

- Newly poured slabs

2.2 Whitening or Cloudy Film Formation

When moisture evaporates through the coating too rapidly, or the acrylic film traps water during curing, the surface may develop:

- A cloudy white appearance

- Soft, under-cured film

- Localized wrinkling

This is common when the coating is applied too thick or under high humidity.

2.3 Blistering and Bubbling

If water vapor cannot escape fast enough, trapped moisture may form bubbles. Causes include:

- High substrate moisture

- High ambient humidity

- Direct sunlight causing rapid surface drying

- Impermeable top layers blocking evaporation

2.4 Delayed Drying and Incomplete Curing

Concrete with high moisture slows the evaporation-based curing process of acrylic. This can result in:

- Weak film formation

- Softness under foot traffic

- Sticky surface

- Poor long-term waterproofing stability

2.5 Mold or Microbial Growth Behind the Coating

If moisture is trapped, microbial growth may occur beneath the coating in dark, damp, poorly ventilated areas.

The risks emphasize one principle: Acrylic coatings can be applied to damp concrete but must avoid overly wet or water-saturated surfaces. With proper moisture control and surface preparation, the risks can be minimized.

3. Types of Acrylic Waterproof Coatings Suitable for Damp Concrete

Not all acrylic coatings are equal. Some are standard wall coatings, while others are specially designed for waterproofing on damp substrates.

Below are the types most suitable for damp concrete.

3.1 High-Penetration Acrylic Primers

These primers contain fine polymer particles that penetrate deeply into the pores of damp concrete. Benefits include:

- Strong adhesion even when concrete is slightly wet

- Enhanced bonding between topcoat and substrate

- Improved resistance to peeling and blistering

They stabilize the base layer, making the substrate more uniform for waterproofing.

3.2 Fast-Drying, Moisture-Tolerant Acrylic Coatings

Specialized acrylic waterproof coatings are engineered to cure even when ambient humidity is high. Their advantages:

- Faster initial set

- Reduced whitening risk

- Better early-stage hardness

- Improved crack-bridging on damp surfaces

These formulas are ideal for humid climates and rainy seasons.

3.3 Elastomeric Acrylic Waterproof Coatings

These coatings include cross-linking polymers that provide:

- High flexibility

- Long-term UV resistance

- Strong adhesion to damp concrete surfaces

They are commonly used in roofing, balconies, and external walls.

4. Essential Surface Preparation Steps for Damp Concrete

Even though acrylic coatings tolerate moisture, correct substrate preparation is still crucial.

4.1 Remove All Standing Water

Visible water must be wiped, blown, or vacuumed off. Standing water will:

- Prevent adhesion

- Dilute the coating

- Cause blistering

4.2 Handle Any Active Leakage

Before applying acrylic waterproof coatings:

- Seal leakage points with injection grout.

- Repair cracks with polyurethane or epoxy grout.

- Ensure moisture is residual, not active.

Acrylic coatings cannot resist pressurized leakage during construction.

4.3 Clean the Substrate Thoroughly

Concrete must be free from:

- Dust

- Oil

- Loose powder

- Cement laitance

- Molds or algae

This ensures that the coating bonds directly to the concrete, not to impurities.

4.4 Moisture Testing (Practical On-Site Methods)

Contractors can quickly test moisture using:

- A plastic sheet test (condensation means high moisture)

- A moisture meter

- Touch inspection combined with visual observation

If the surface shows “SSD” conditions—damp but not wet—it is suitable for acrylic application.

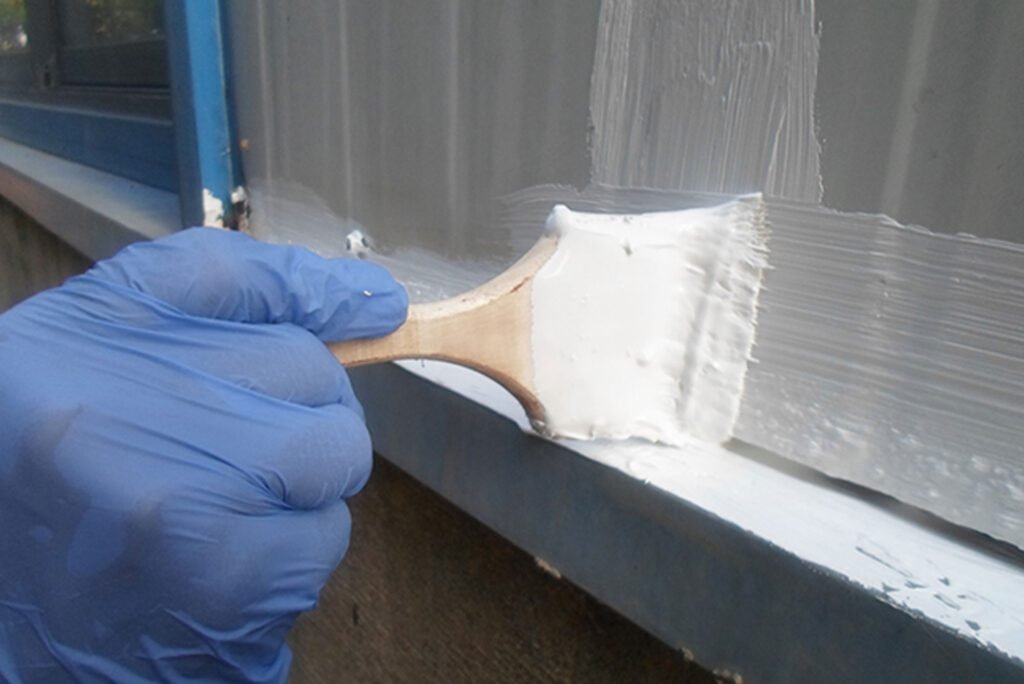

4.5 Apply a Moisture-Compatible Primer

A primer is essential to:

- Lock in surface moisture

- Improve adhesion

- Reduce blistering risk

- Enhance uniformity

5. Environmental Conditions for Applying Acrylic on Damp Concrete

Environmental conditions significantly affect film formation.

5.1 Temperature Requirements

Ideal temperature: 10°C – 35°C

Below 10°C, drying is too slow.

Above 35°C, surface drying is too rapid and causes cracks and bubbles.

5.2 Humidity Considerations

Humidity below 85% is recommended.

High humidity slows curing and increases whitening risk.

5.3 Ventilation

Good airflow allows gradual evaporation, preventing:

- Trapped moisture

- Film defects

- Slow curing

Indoor areas require forced ventilation.

5.4 Layer Thickness Control

Acrylic coatings should be applied in thin layers, usually:

- 0.3–0.5 mm per coat

- 2–3 coats total

Thick layers trap moisture and delay curing.

6. Troubleshooting: What If Problems Occur After Application?

If the coating was applied on a damp substrate and problems appear, here are solutions.

6.1 Blistering

Solutions:

- Cut open blisters to evaluate moisture

- Remove defective areas

- Improve ventilation

- Reapply primer and topcoat

6.2 Whitening

Solutions:

- Allow additional drying

- Apply a thin corrective coat

- Avoid thick application next time

6.3 Poor Adhesion

Solutions:

- Mechanically remove loose coating

- Reapply primer suitable for damp substrates

6.4 Soft or Sticky Film

Solutions:

- Increase drying time

- Use low-temperature or high-humidity tolerant acrylic systems

7. Why Contractors Choose YURU Waterproof Acrylic Coatings?

YURU Waterproof specializes in producing acrylic waterproof coatings, polyurethane coatings, injection waterproofing materials, and engineered waterproofing systems for large-scale construction and industrial projects.

Benefits of YURU Acrylic Waterproof Coatings

- Specially formulated for damp concrete substrates.

- High-penetration and high-adhesion primers.

- Anti-blister, anti-whitening technology.

- Ideal for roofs, walls, basements, and wet areas.

- Consistent bulk supply for wholesalers and contractors.

- OEM/ODM customization available.

Contractors trust YURU Waterproof because our products are engineered for real jobsite conditions, not just laboratory standards.

FAQ:

1. Can acrylic waterproof coatings fully adhere to damp concrete?

Yes. As long as the concrete is damp—not wet or leaking—acrylic coatings can form strong adhesion.

2. What is the acceptable moisture level for acrylic coatings?

SSD (saturated-surface-dry) conditions are acceptable. Visible water must be removed.

3. Will acrylic coatings bubble on damp concrete?

They may, if the substrate is too wet or the coating is applied too thick. Using a proper primer prevents this.

4. Are acrylic coatings better than polyurethane on damp concrete?

Acrylic is more moisture-tolerant, but polyurethane performs better in wet or submerged environments. The choice depends on the project.

5. Can acrylic be used indoors where humidity is high?

Yes, but ventilation must be ensured to prevent delayed drying.

6. Should I use a primer before applying acrylic coatings on damp concrete?

Yes. A moisture-compatible primer significantly improves bonding and reduces failures.

Conclusion

Acrylic waterproof coatings can be applied on damp concrete substrates, as long as the moisture level is controlled and the concrete surface is not actively wet or leaking. Their water-based formulation and tolerance for mildly damp surfaces make them ideal for large-scale construction, renovation projects, rooftop waterproofing, and external wall protection.

When combined with proper surface preparation, moisture control, and environmental management, acrylic coatings deliver reliable waterproofing performance even in challenging climates.

For contractors, wholesalers, and engineering firms seeking stable supply and professional products, YURU Waterproof provides complete acrylic waterproofing systems designed for real construction environments.

YURU Product solutions

Waterproof Coating

- One-component oil-based polyurethane waterproof coating

- One-component water-based polyurethane waterproof coating

- Two-component polyurethane waterproof coating

- Two-component 6.0Mpa polyurethane waterproof coating

- Transparent Waterproof Glue

- Nano Invisible Waterproof Agent

- Silicone Waterproof Coating

- Acrylic Waterproof Coating For Metal Roof

- JS Polymer Waterproof Coating

- High Elastic Liquid Rubber Waterproof Coating

- Cement-based Penetrating Crystallization Waterproof Coating