Epoxy Color Sand Floor Paint for Marble Effect

Introduction: A Manufacturer-Level Guide to Seamless Decorative Flooring Solutions

In modern construction, architects, developers, and facility owners now demand floors that combine:

- High-end aesthetics

- Structural integrity

- Hygiene and easy maintenance

- Long-term durability

This is where epoxy color sand floor paint has emerged as a practical and technical alternative.

Rather than imitating marble through printed textures or tiles, epoxy color sand systems rebuild the visual language of stone using mineral aggregates and resin technology—creating a seamless, monolithic surface with controlled texture and depth.

At YURU Waterproof, epoxy color sand flooring is not treated as a decorative coating, but as a complete engineered flooring system.

1. What Is Epoxy Color Sand Floor Paint?

Epoxy color sand floor paint is a resin-based decorative flooring system composed of:

- High-purity epoxy resin (binder).

- Selected natural or synthetic colored aggregates.

- Functional additives for flow, bonding, and curing control.

Unlike conventional epoxy coatings, color sand systems rely on particle structure, not pigments alone.

Key Structural Characteristics:

- Multi-layer, seamless construction

- High aggregate content

- Zero grout lines

- Adjustable surface texture

This structure allows the floor to visually resemble marble, terrazzo, or natural stone.

2. Why More Projects Choose Color Sand Over Natural Marble?

2.1 Structural Integrity Without Weak Points

Marble tiles introduce inherent risks:

- Grout line contamination

- Differential movement cracking

- Hollow spots and delamination

Epoxy color sand floors form a continuous bonded layer, eliminating:

- Joint failure

- Water ingress pathways

- Differential settlement issues

2.2 Design Freedom Beyond Stone Limitations

Epoxy color sand flooring allows:

- Custom color blending

- Controlled veining effects

- Project-specific patterns

2.3 Lifecycle Cost Advantage

While marble may appear premium upfront, long-term costs include:

- Polishing

- Sealing

- Crack repair

- Replacement

Epoxy color sand floors require minimal maintenance, significantly lowering total ownership cost.

3. Three Technical Factors That Define a Real Marble Effect

Not all color sand floors look alike. True marble-like depth depends on engineering precision.

3.1 Aggregate Selection and Grading

- Natural mineral appearance

- Controlled particle size distribution

- Color stability under UV exposure

YURU selects aggregates through multi-stage screening to ensure visual consistency and structural density.

3.2 Epoxy Resin Transparency and Flow

Resin quality determines:

- Optical depth

- Aggregate visibility

- Final surface clarity

Low-grade resins cause clouding and dull finishes. YURU formulations prioritize high optical clarity and controlled viscosity.

3.3 Application Technique and Texture Control

The same material can yield vastly different results depending on:

- Trowel technique

- Layer timing

- Aggregate orientation

This is why epoxy color sand flooring is system-based, not product-based.

4. Where Epoxy Color Sand Marble-Effect Flooring Works Best?

4.1 Commercial and Public Spaces

- Shopping malls

- Hotel lobbies

- Exhibition halls

Advantages:

- Visual impact

- Wear resistance

- Easy cleaning

4.2 High-End Residential Projects

- Villas

- Private clubs

- Penthouse interiors

Benefits:

- Seamless elegance

- Warm tactile feel

- Custom design options

4.3 Healthcare and Clean Environments

- Clinics

- Laboratories

- Wellness centers

Key properties:

- No grout lines

- Easy sanitation

- Chemical resistance

5. Construction Risks and Why Supplier Expertise Matters

Epoxy color sand flooring is not a forgiving system.

Common failures stem from:

- Inconsistent aggregate supply

- Poor resin compatibility

- Inexperienced installation guidance

Failures often appear as:

- Color blotching

- Weak bonding

- Surface pinholes

Choosing the right manufacturer is risk management, not brand preference.

6. How to Evaluate a Professional Epoxy Color Sand Supplier?

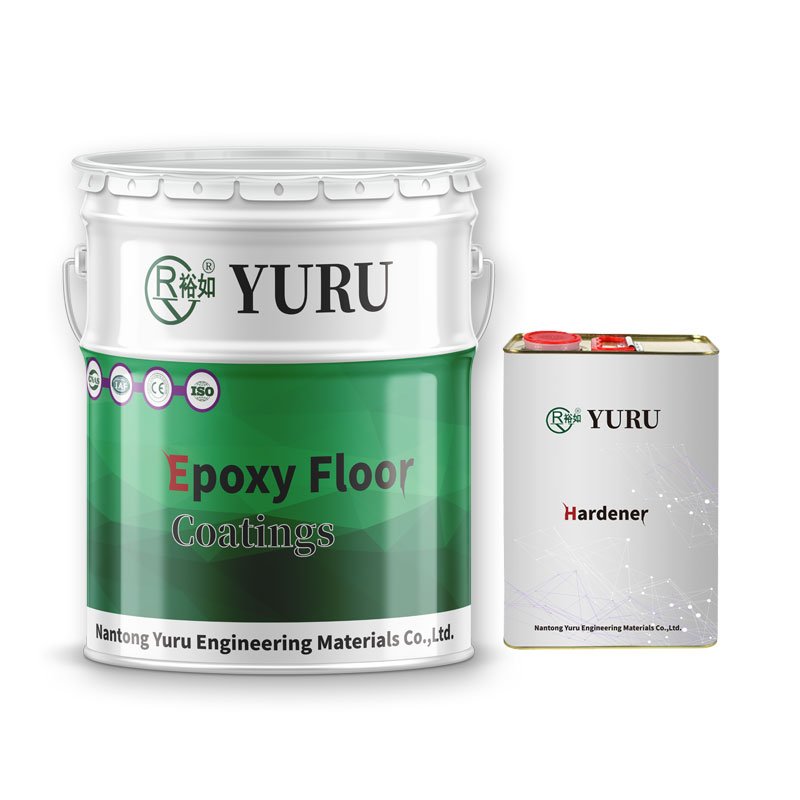

6.1 System Completeness

A professional supplier provides:

- Primer

- Color sand layer

- Sealing/topcoat

- Technical datasheets

Not just “materials in buckets”.

6.2 Customization Capability

True manufacturers can:

- Adjust resin rheology

- Modify aggregate blends

- Support design intent

This is essential for marble-effect realism.

6.3 Technical Support

On-site or remote guidance is often the difference between:

- A showcase floor

- A costly remake

7. Why YURU Epoxy Color Sand Systems Stand Out?

At YURU, epoxy color sand flooring is engineered as a decorative structural layer, not a cosmetic finish.

Our Key Advantages:

- Carefully graded natural color sands.

- High-clarity, low-yellowing epoxy resin.

- Proven system compatibility.

- Project-based technical support.

FAQs: Epoxy Color Sand Floor Paint

1. Is epoxy color sand flooring slippery?

Surface texture can be adjusted to meet slip-resistance requirements.

2. How long does installation take?

Typically 2–4 days depending on area and design.

4. Can damaged areas be repaired?

Yes, localized repairs are possible without visible joints.

5. Can patterns be customized?

Absolutely. Color and pattern customization is a key advantage.

Conclusion

Epoxy color sand floor paint redefines what decorative flooring can be.

It offers:

- Seamless construction

- Design freedom

- Structural reliability

- Long-term value

For projects where aesthetics and performance must coexist, epoxy color sand marble-effect flooring is not an alternative—it is an upgrade.

Looking to achieve marble aesthetics? Contact YURU today to receive:

- Sample boards

- Project-specific recommendations

Let your floor perform as beautifully as it looks.