Best Applications for Acrylate Grouting Material: Tunnels, Dams, and Curtains

Introduction:

Waterproofing and leak prevention problems have always been present during the construction of infrastructure projects such as underground works and hydraulic engineering projects. Whether it’s continuous leakage in tunnels or slow seepage in dams, these issues compromise the durability, safety, and lifespan of the structures.

Unlike traditional sealing materials and polyurethane grouting systems, acrylate grouting materials offer the following unique advantages:

- Ultra-low viscosity

- Ability to penetrate into fine cracks

- Adjustable gel time

- Long-term water chemical stability

This article will explore the optimal application areas of acrylate grouting materials and, more importantly, explain why engineers are increasingly using them in tunnels, dams, and curtain grouting systems.

1. What Is Acrylate Grouting Material? Understanding the Fundamentals

Acrylate grouting material belongs to the family of hydrophilic chemical grouts.

Its defining characteristic is viscosity close to water, typically ranging between 2–5 mPa·s, allowing it to flow into microcracks, pores, and granular soil structures that other grouts cannot access.

1.1 Chemical Mechanism and Gel Formation

After injected, the liquid acrylate grout will react to create a flexible hydrogel that:

- Occupies voids and fissures

- Bonds mechanically with surrounding substrates

- Maintains moisture equilibrium with groundwater

1.2 Key Performance Characteristics

- Ultra-low viscosity: penetrates cracks < 0.1 mm.

- Adjustable gel time: seconds to tens of minutes.

- Hydrophilic behavior: remains effective under permanent water exposure.

- Minimal expansion pressure: safe for sensitive structures.

These properties explain why acrylate grout is rarely used for emergency water stopping, but frequently specified for long-term seepage control and curtain grouting.

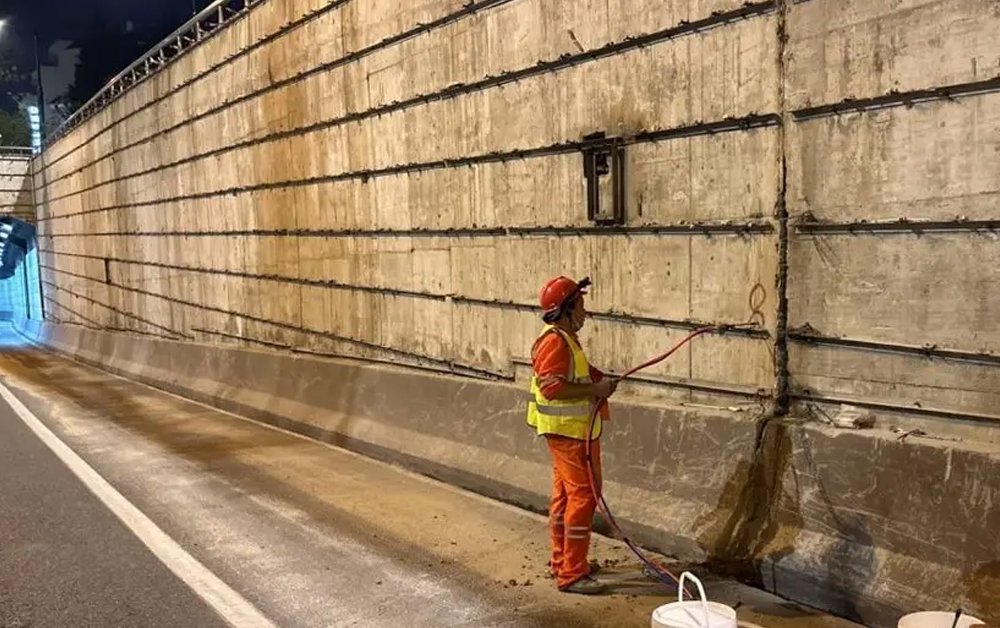

2. Why Acrylate Grouting Is Ideal for Tunnel Waterproofing Projects?

Tunnels represent one of the most demanding environments for waterproofing materials.

2.1 Common Tunnel Leakage Scenarios

- Continuous seepage through segment joints.

- Water migration behind secondary linings.

- Infiltration along construction joints and cold joints.

- Groundwater pressure acting on fractured rock zones.

Traditional rigid grouts often fail because they cannot penetrate deeply enough, leaving active water channels untreated.

2.2 How Acrylate Grouting Solves Tunnel Leakage at the Source?

Acrylate grout’s low viscosity allows it to follow water paths, migrating naturally into fine fissures where seepage originates. Once gelled, it forms a continuous impermeable zone.

This makes acrylate grouting particularly effective for:

- Metro tunnels

- Railway tunnels

- Utility and service tunnels

- Underground pedestrian passages

2.3 Long-Term Tunnel Performance Advantages

Unlike PU foams that prioritize rapid expansion, acrylate grout focuses on durability.

Its hydrogel structure maintains performance even under:

- Permanent groundwater exposure

- Cyclic wet-dry conditions

- Minor structural movement

This explains why many infrastructure authorities specify acrylate grouting as a secondary waterproofing measure after structural stabilization.

3. Acrylate Grouting in Dam and Hydraulic Structures

Dams and water-retaining structures present a different set of challenges.

3.1 Seepage Risks in Dams

- Progressive erosion of foundation soils

- Internal piping through fissured rock

- Long-term uplift pressure accumulation

Short-term solutions may mask symptoms without addressing seepage paths at depth.

3.2 Why Acrylate Grout Is Used in Dam Foundations?

Acrylate grouting material excels in dam projects because it can:

- Penetrate fractured rock foundations.

- Seal fine fissures beyond cement grout reach.

- Maintain flexibility under hydraulic loading.

Its compatibility with both concrete and geological substrates makes it suitable for foundation curtain grouting.

3.3 Long-Term Stability Under Continuous Water Load

A properly formulated acrylate grout remains stable in saturated conditions.

Unlike some chemical grouts that harden and crack, acrylate maintains elasticity, reducing the risk of reactivation of seepage channels.

This performance profile has made it a preferred material in:

- Concrete gravity dams

- Earth-fill dams

- Spillway foundation treatments

4. Curtain Grouting Systems: Where Acrylate Grout Truly Excels

The purpose of curtain grouting is to create a continuous underground barrier that reduces groundwater flow to an acceptable level.

4.1 Why Material Selection Is Critical:

Curtain grouting often targets:

- Fine sands

- Fractured rock

- Mixed soil strata

Materials with high viscosity or uncontrolled expansion simply cannot achieve the required penetration.

4.2 Advantages of Acrylate Grout in Curtain Applications

- Deep penetration radius

- Predictable gel time for staged injection

- Uniform barrier formation

Acrylate grout allows engineers to engineer the permeability reduction, rather than relying on brute-force filling.

4.3 Typical Curtain Grouting Applications

- Dam foundations

- Cut-off walls

- Underground powerhouses

- Deep excavation support

5. Construction Controllability and Risk Management

From an execution standpoint, acrylate grouting requires precision, not improvisation. Acrylate grouting requires a two-component grouting pump.

Key control parameters include:

- Gel time calibration

- Injection pressure management

- Mixing accuracy

When properly managed, the system offers exceptional predictability, which is why experienced contractors favor it for sensitive structures.

6. How to Determine Whether Acrylate Grouting Is Right for Your Project?

Acrylate grout is best suited when:

- Leakage originates from micro-permeable paths.

- Long-term seepage control is required.

- Structural movement is expected.

It is less suitable for emergency water stoppage or large void filling.

7. Environmental and Regulatory Considerations

Modern acrylate grouting materials are formulated to meet strict environmental standards.

Once cured, they are chemically stable and suitable for:

- Groundwater-adjacent structures.

- Environmentally sensitive zones.

- Infrastructure projects with long service life requirements.

8. YURU Waterproof: Systematic Acrylate Grouting Solutions

YURU Waterproof supplies engineered acrylate grouting systems for tunnels, dams, and curtain grouting projects worldwide.

Our approach focuses on:

- Project-specific formulation

- Technical support during material selection

- Long-term performance validation

Rather than offering a single “universal” grout, YURU provides tailored solutions based on geology, water pressure, and construction method.

FAQs: Acrylate Grouting Material

1. Is acrylate grouting permanent?

When properly applied, acrylate grout offers long-term seepage control, often exceeding 20 years in stable conditions.

2. Can acrylate grout stop active water flow?

It is better suited for seepage control than emergency water stoppage. High-flow leaks often require a staged approach.

3. Is acrylate grout environmentally safe?

Modern formulations meet international environmental standards when cured correctly.

4. Can it be used with other grouting systems?

Yes. It is often combined with cement or PU systems in complex projects.

Conclusion

If your project involves tunnels, dams, or curtain grouting systems where long-term seepage control matters, acrylate grouting material deserves serious consideration.

Contact YURU Waterproof to receive project-specific acrylate grouting recommendations, technical data, and sample support—so leakage is solved at its source, not repeatedly patched.