A Complete Guide to Epoxy Resin Grouting Material in Waterproofing Applications

Crack repair and waterproofing remain two of the most important challenges in modern concrete engineering. Whether the issue involves water seepage, structural fatigue, or long-term durability demands, the choice of injection grout directly determines the performance of the entire waterproofing system.

Among all commonly used injection grouting materials, epoxy resin grouts play a uniquely important role—particularly in structural reinforcement and permanent crack sealing. Compared with polyurethane chemical grouts, epoxy delivers higher strength, stronger adhesion, and long-term stability, making it an essential material for contractors working on tunnels, water-retaining structures, basements, and large-scale infrastructure.

The goal is to help you understand how epoxy resin grout works, when it should be used, and how to evaluate the correct material for your project—with insights from YURU Waterproof, a professional manufacturer specializing in waterproofing and injection products.

1. What Is Epoxy Resin Grouting Material?

Epoxy resin grouting materials are A/B two-component structural injection systems designed for the permanent repair of concrete cracks.

1.1 Two-Component System

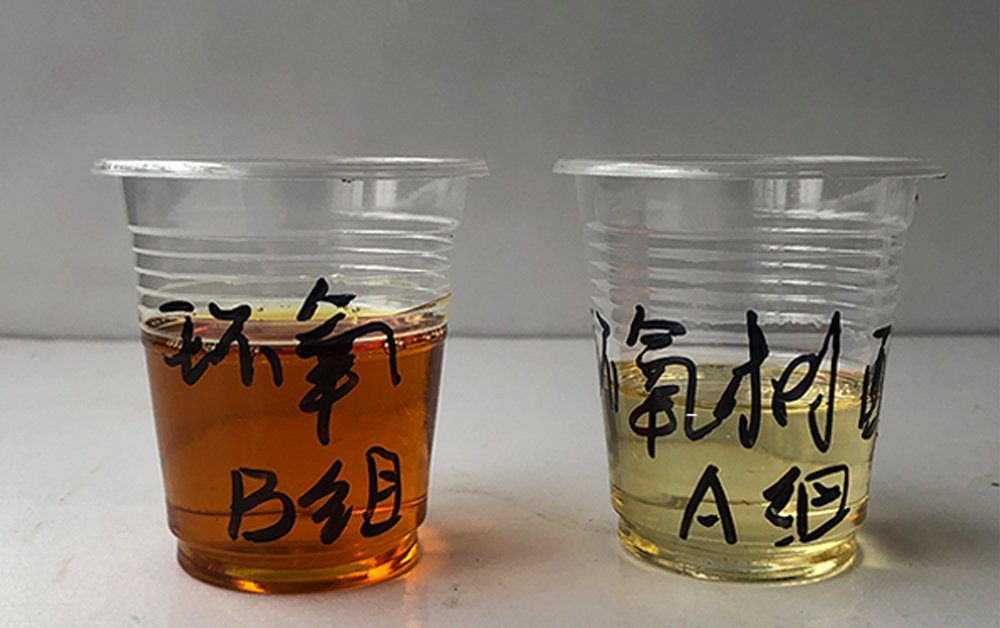

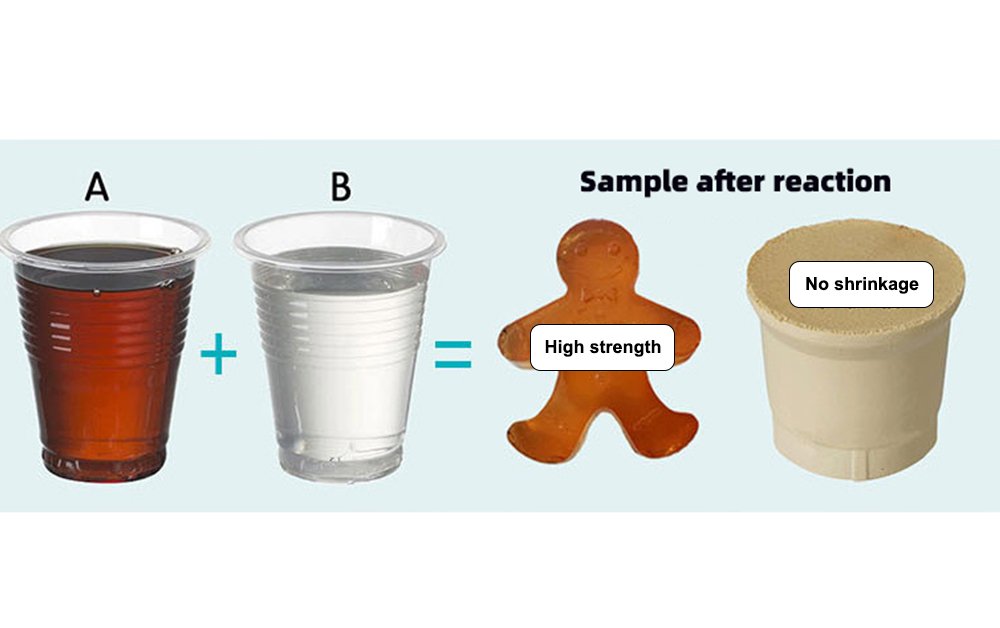

A complete epoxy grout includes:

- Component A (Epoxy Resin)

- Component B (Curing Agent / Hardener)

When mixed together in the correct ratio, the two components undergo a chemical curing reaction that produces a high-strength, dense, solid material capable of restoring load-bearing capacity.

1.2 How Epoxy Grout Works:

Epoxy resin grout:

- flows into cracks through low or ultra-low viscosity

- bonds chemically with concrete

- cures into a rigid, high-strength material

- reinforces and restores the original structural integrity

Unlike polyurethane grouts, epoxy does not rely on water to react, and does not expand. Instead, it forms strong, stable, and durable crack repair structures.

1.3 Key Performance Advantages:

Compared with conventional cement-based grouts or chemical foams, epoxy resin grouting materials provide:

- exceptional bonding strength

- high compressive and tensile performance

- long-term stability (20–50+ years depending on conditions)

- chemical resistance

- minimal shrinkage

- structural reinforcement capabilities

1.4 Role in Waterproofing Systems

In waterproofing engineering, epoxy grouting materials serve four critical functions:

- Structural crack repair

- Anti-seepage sealing

- Restoration of concrete durability

- Preconditioning cracks before applying surface waterproofing layers

Because the cured epoxy material is impermeable and extremely strong, it ensures that repaired cracks do not reopen under stress—a major reason engineers rely on epoxy for permanent solutions.

2. Where Is Epoxy Resin Grouting Material Used?

Epoxy injection grouts are used across a wide range of engineering projects, especially where cracks threaten structural safety or long-term waterproofing.

Below are the most common applications.

2.1 Water-Retaining Concrete Structures

Epoxy is widely applied in:

- water tanks

- sewage treatment facilities

- desalination plants

- reservoirs

- dams

Because these structures cannot tolerate cracking due to hydrostatic pressure, epoxy is required for permanent crack sealing.

2.2 Metro & Tunnel Infrastructure

For tunnel waterproofing systems, epoxy is essential when dealing with:

- static cracks in tunnel linings

- segment joint reinforcement

- concrete delamination repair

In metro projects, engineers typically use epoxy grouts before applying polyurethane for water interception, creating a combined waterproofing system.

2.3 Basements, Foundations & Underground Garages

Underground structures often face cracking due to:

- soil settlement

- vibration

- shrinkage stresses

Epoxy is ideal for restoring the load-bearing capacity of cracked walls, slabs, and beams.

2.4 Bridges & Elevated Structures

Epoxy injection is a standard practice in bridge maintenance for:

- restoring cracks in piers, girders, decks

- improving durability

- preventing corrosion due to water ingress

2.5 Industrial Facilities

Chemical-resistant epoxy grouts are especially suitable for:

- factories

- warehouses

- power plants

2.6 Environments Where Epoxy Is NOT Recommended

People frequently ask where epoxy should not be used. Key limitations:

- dynamic cracks

- wet cracks with active water leakage

- expansion joints or movement joints

- environments requiring flexible sealing

These are better suited for polyurethane injection grouts.

3. Construction Process of Epoxy Resin Grouting Material

Epoxy injection is a precision task requiring strict control. Below is the industry-standard procedure used by professional contractors.

3.1 Step 1 – Crack Cleaning & Surface Preparation

- Remove dust, laitance, loose concrete.

- Deep clean using compressed air or vacuum.

- Ensure surface is dry.

3.2 Step 2 – Surface Sealing

Contractors use epoxy paste or rapid-setting mortar to seal:

- crack surfaces

- injection paths

- voids around crack mouths

This ensures grout flows inside rather than leaking outward.

3.3 Step 3 – Installing Injection Ports (Packers)

Ports are placed at intervals based on:

- crack depth

- width

- injection pressure

- viscosity of epoxy

Spacing typically ranges from 20–30 cm for precise injection.

3.4 Step 4 – Mixing Component A & B

Critical parameters:

- correct ratio (varies by product).

- mechanical mixing for uniformity.

- avoid introducing air.

- mix small batches to prevent premature curing.

3.5 Step 5 – Injection Process

- Begin from lowest port.

- Monitor pressure and material flow.

- Check for material emerging from adjacent ports.

- Close ports as resin fills the crack.

3.6 Step 6 – Curing & Solidification

Epoxy typically cures in 6–24 hours depending on:

- temperature

- product formulation

- humidity

3.7 Step 7 – Finishing & Inspection

- Remove ports

- Grind sealed crack surfaces

- Conduct hammer-sounding or ultrasound inspection

3.8 Common Issues & Solutions

| Issue | Cause | Solution |

|---|---|---|

| Grout not flowing | Crack blocked | Use ultra-low viscosity epoxy |

| Early curing | Long mixing time | Mix smaller batches |

| Leakage from crack surface | Poor sealing | Re-seal with epoxy paste |

| Crack not fully filled | Incorrect pressure | Adjust or re-inject |

4. Types of Epoxy Resin Grouting Materials

Construction environments vary. Selecting the correct type ensures successful injection.

4.1 Low-Viscosity Epoxy

Characteristics:

- suitable for cracks 0.2–0.3 mm

- good penetration

Used for:

- general structural repairs.

- non-pressurized injections.

4.2 Ultra-Low Viscosity Epoxy

Characteristics:

- penetrates cracks <0.1 mm

- excellent flowability

Ideal for:

- hairline cracks

- deep narrow cracks

4.3 High-Strength Structural Epoxy

Characteristics:

- very high bonding strength

- enhances structural performance

Applications:

- bridges

- load-bearing beams

- industrial equipment foundations

4.4 Fast-Curing Epoxy

Characteristics:

- cures rapidly

- suited for high-frequency vibration environments

Applications:

- highway repairs

- emergency crack sealing

4.5 How to Choose the Right Type:

Consider:

- crack width

- crack depth

- temperature

- structural strength requirements

- injection equipment type

Incorrect model selection is the MOST common cause of a failed epoxy injection.

5. Why Choose YURU Waterproof’s Epoxy Resin Grouting Materials?

YURU Waterproof specializes in professional waterproofing materials, polyurethane injection products, epoxy grouting systems, and industrial coatings for global contractors.

Below is what differentiates YURU in the global market:

5.1 High Penetration Ability

Our epoxy systems feature:

- ultra-low viscosity formulation

- deep crack penetration

- strong flow characteristics

- stable curing even in narrow cracks

5.2 Superior Mechanical Strength

YURU epoxy provides:

- high tensile performance

- strong substrate adhesion

- long-term anti-aging stability

- resistance to chemical corrosion

5.3 Professional Engineering Support

We support:

- technical data sheets

- project material selection

- OEM/ODM manufacturing

- engineering guidance

5.4 Large-Scale OEM & Export Capability

Our epoxy injection products are widely exported to:

- Southeast Asia

- Middle East

- South America

- Eastern Europe

- Africa

Suitable for distributors and large contractors.

5.5 Suitable for Major Infrastructure Projects

YURU epoxy resin grouting materials are commonly used in:

- tunnels & metros

- dams

- hydropower stations

- basements

- bridges

- wastewater plants

6. Conclusion

Epoxy resin grouting materials play a central role in modern waterproofing and structural repair. While polyurethane grouts are ideal for water interception and fast leak sealing, epoxy resin grouts are unmatched for permanent crack repair, structural reinforcement, and long-term waterproofing reliability.

With the right crack assessment, correct grout selection, and professional construction process, epoxy grouting can extend the service life of concrete structures for decades.

YURU Waterproof provides advanced epoxy resin grouting systems designed for global engineering professionals—supported by technical expertise, OEM capability, and long-term supply stability.

For distributors, contractors, or project owners seeking reliable and high-performance epoxy grouting materials, YURU Waterproof remains a trusted partner in the waterproofing industry.

YURU Product solutions

Waterproof Coating

- One-component oil-based polyurethane waterproof coating

- One-component water-based polyurethane waterproof coating

- Two-component polyurethane waterproof coating

- Two-component 6.0Mpa polyurethane waterproof coating

- Transparent Waterproof Glue

- Nano Invisible Waterproof Agent

- Silicone Waterproof Coating

- Acrylic Waterproof Coating For Metal Roof

- JS Polymer Waterproof Coating

- High Elastic Liquid Rubber Waterproof Coating

- Cement-based Penetrating Crystallization Waterproof Coating