A Complete Guide to Injection Grouting Materials

Introduction

Injection grouting has become a go-to solution for restoring structural integrity, stopping water leaks, and filling voids in concrete and masonry. Whether you’re repairing a basement wall or reinforcing an aging tunnel, choosing the right grouting material is critical to long-term success.

In this guide, we’ll introduce the different types of injection grouting materials, their specific uses, and how to select the right product for your application.

What Is Injection Grouting?

Injection grouting is the process of injecting a flowable material—known as grout—into cracks, voids, joints, or porous substrates. Once injected, the grout hardens or expands to form a seal, reinforce the structure, or block water pathways.

It’s widely used in:

- Concrete repair

- Leak sealing in basements and tunnels

- Ground stabilization

- Joint and void filling

- Seismic retrofitting

The effectiveness of injection grouting largely depends on the type of grout used and how well it matches the structure’s needs.

Types of Injection Grouting Materials

There is no one-size-fits-all grout. Each material has unique characteristics that make it suitable for certain environments and repair objectives. Below are the most common types of injection grouting materials:

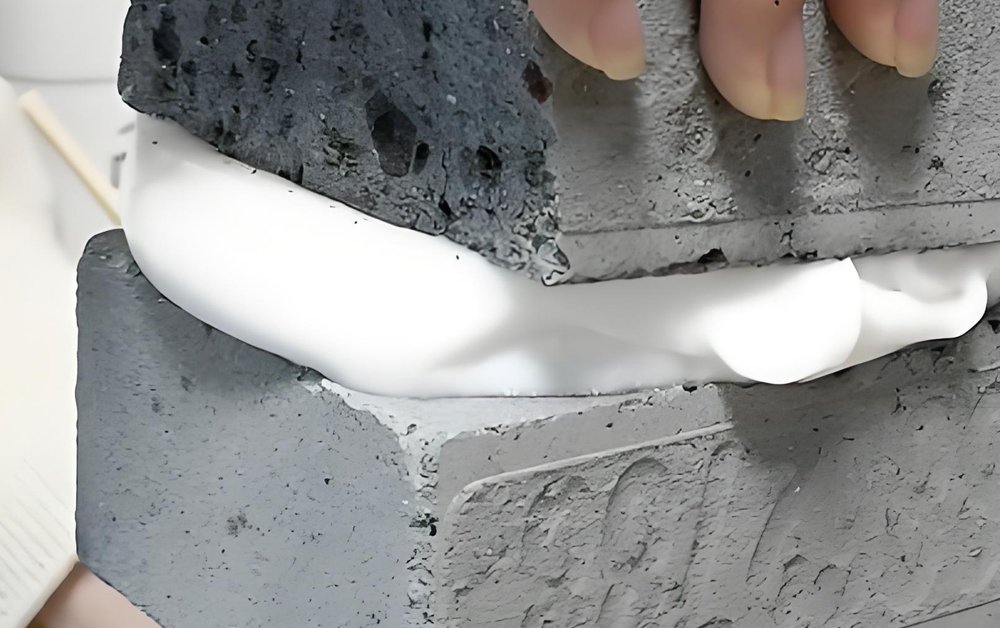

1. Cementitious Grouting

Cement-based grouts are among the most traditional and economical options. They are typically used for:

- Filling large voids or honeycombs in concrete

- Baseplate anchoring

- Structural support repairs

While not ideal for waterproofing, they offer excellent volume stability and compressive strength.

2. Chemical Grouting

Chemical grouts are synthetic polymers that are injected into very fine cracks and joints. Subcategories include:

• Polyurethane Grouting

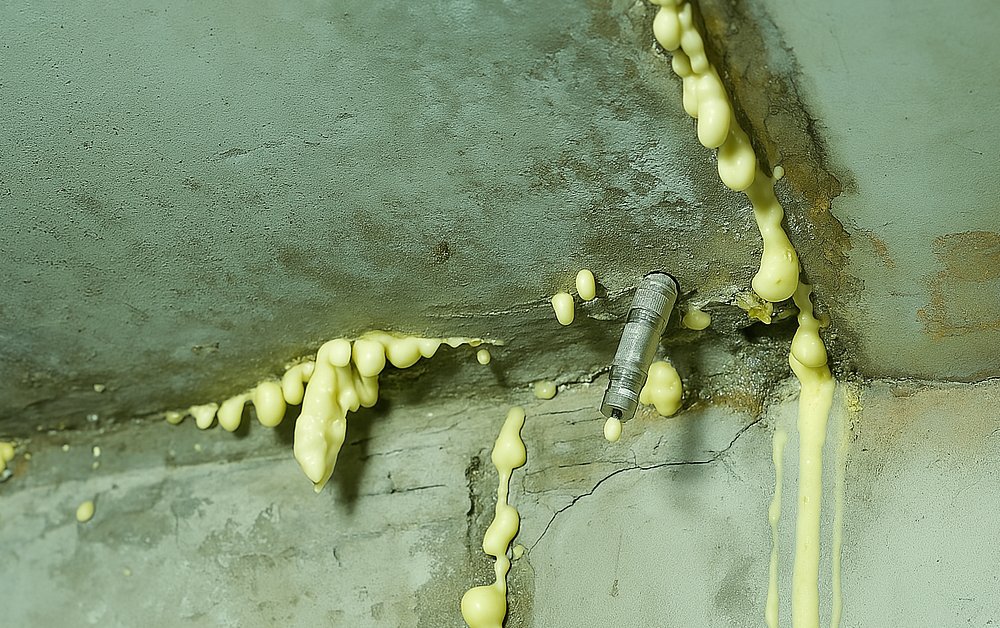

- Reacts quickly with water to form flexible foam.

- Ideal for sealing water ingress in basements, subways, and retaining walls.

- Highly elastic and can accommodate structural movement.

• Epoxy Grouting

- Strong, rigid material suitable for structural bonding.

- Fills cracks and restores load-carrying capacity in beams, columns, or slabs.

- Low shrinkage and high chemical resistance.

• Acrylic Gel Grouting

- Ultra-low viscosity allows deep penetration into hairline cracks.

- Forms a long-lasting, flexible waterproof barrier.

- Excellent choice for below-grade waterproofing applications.

How to Choose the Right Grouting Material?

Choosing the best grouting material depends on the following factors:

| Criteria | What to Consider |

| Crack Width | Wider cracks may require cementitious grout; microcracks suit gels or PU |

| Structural Role | Epoxy is best for load-bearing repairs |

| Water Exposure | Polyurethane or acrylic gels excel in wet environments |

| Substrate Condition | Old, porous concrete may need lower-viscosity materials |

| Movement Accommodation | Flexible grouts like PU or acrylic are preferred |

Consulting with a technical expert or supplier ensures you choose a material tailored to your site’s unique needs.

Benefits of Injection Grouting

✅ Strengthens structures without the need for major demolition.

✅ Seals water leaks and stops further water ingress.

✅ Improves building safety by stabilizing foundations or walls.

✅ Cost-effective alternative to full replacement or reconstruction.

✅ Minimizes downtime for infrastructure and commercial properties.

Common Applications of Injection Grouting

Grouting is used across various industries and building types:

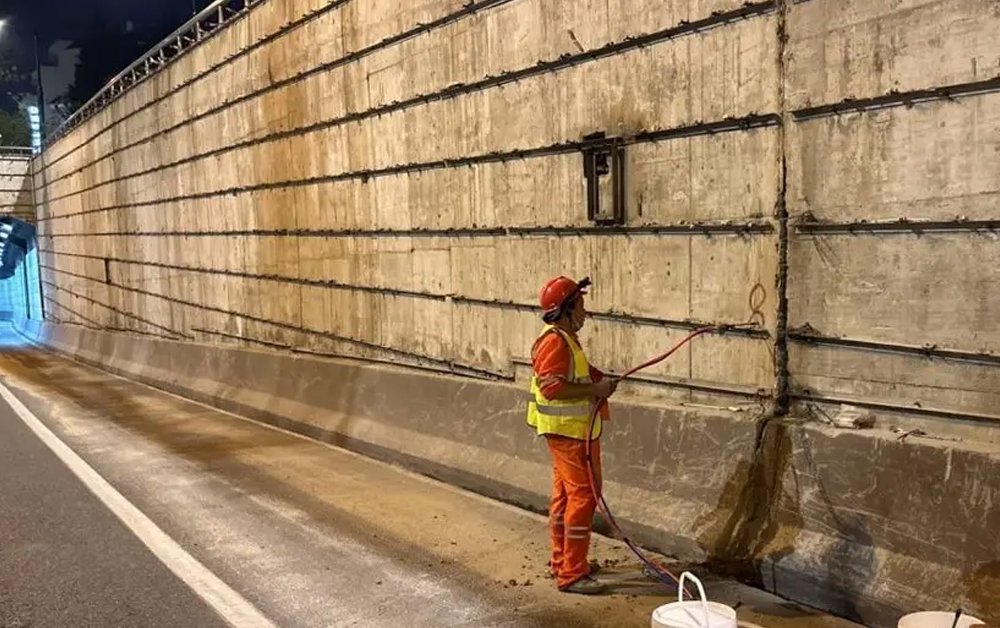

- Basements and foundations: Leak sealing and soil stabilization.

- Tunnels and subway systems: Waterproofing and void filling.

- Bridges and highways: Joint stabilization and crack repair.

- Industrial floors: Filling slab voids and supporting heavy loads.

- Water tanks and dams: Sealing structural leakage points.

Conclusion

Injection grouting is a versatile, efficient, and highly effective method for restoring structural integrity and waterproofing problems. By understanding the strengths and uses of different grouting materials, you can make informed decisions and ensure long-lasting results.

If you’re unsure which injection material best suits your project, consulting a specialized supplier like YURU Waterproof can save you time, money, and risk.

Contact us today for expert guidance and premium injection grouting materials tailored to your next project.

YURU Product solutions

Waterproof Coating

- One-component oil-based polyurethane waterproof coating

- One-component water-based polyurethane waterproof coating

- Two-component polyurethane waterproof coating

- Two-component 6.0Mpa polyurethane waterproof coating

- Transparent Waterproof Glue

- Nano Invisible Waterproof Agent

- Silicone Waterproof Coating

- Acrylic Waterproof Coating For Metal Roof

- JS Polymer Waterproof Coating

- High Elastic Liquid Rubber Waterproof Coating

- Cement-based Penetrating Crystallization Waterproof Coating