Advantages of Polyurea Grouting Fluid in Concrete Crack Repair

Introduction

Concrete is the backbone of modern infrastructure, yet cracks are inevitable in long-term service. From underground tunnels to large basements and bridges, cracks not only weaken structural integrity but also accelerate corrosion of reinforcing steel due to water ingress. Traditional repair methods often fail to provide durable solutions because of low bonding strength, slow curing, or limited chemical resistance.

This is where polyurea grouting fluid stands out as a reliable choice. Known for its high penetration, rapid reaction, strong adhesion, and exceptional durability, polyurea injection technology has become increasingly popular in large-scale construction projects worldwide.

This article explores the key advantages of polyurea grouting fluid in concrete crack repair, highlights real application scenarios, and demonstrates how YURU Waterproof delivers customized solutions for global contractors, wholesalers, and infrastructure developers.

Common Challenges in Concrete Crack Repair

Concrete structures in industrial and civil projects are constantly exposed to stress, environmental impact, and long-term usage. This leads to:

- Crack propagation: Small cracks expand over time due to load stress or temperature fluctuations.

- Water leakage: Seepage through cracks accelerates steel reinforcement corrosion, reducing structural life.

- Inadequate performance of traditional repair methods: Epoxy or cement grouting may cure slowly, fail to penetrate micro-cracks, or lose effectiveness in wet conditions.

- Long downtime during repair: Extended curing time often delays project schedules, especially in underground or high-traffic areas.

These issues highlight the urgent need for fast, durable, and chemically resistant grouting solutions.

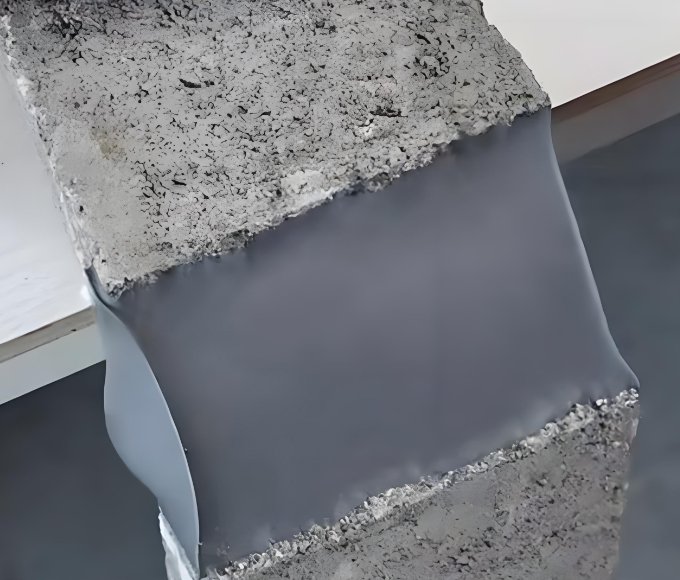

High Penetration for Micro-Crack Sealing

One of the most remarkable advantages of polyurea grouting fluid is its low viscosity and high penetration ability. Unlike cementitious or epoxy-based materials, polyurea grouting fluid can infiltrate micro-cracks and capillary pores that are invisible to the naked eye.

- Deep crack filling: Ensures void-free sealing inside concrete.

- Permanent waterproofing: Prevents water and harmful chemicals from migrating through cracks.

- Enhanced structural stability: Sealed cracks stop further expansion, preserving structural integrity.

This makes polyurea grouting fluid especially effective in subways, tunnels, and underground parking facilities, where fine cracks can quickly lead to water leakage and long-term maintenance issues.

Rapid Curing and Strong Bonding Strength

Time is critical in large-scale infrastructure projects. Polyurea grouting fluid reacts quickly once injected, creating an immediate waterproof barrier.

- Fast curing reaction: Reduces downtime compared to traditional epoxy grouts.

- Superior adhesion: Bonds strongly with surrounding concrete, preventing crack reopening.

- Load-bearing capacity: Maintains strength under constant vibration and heavy load conditions.

For example, in bridge deck repairs, where closure times must be minimized, contractors rely on polyurea injection systems to restore serviceability within hours instead of days.

Long-Lasting Waterproof and Chemical Resistance

Concrete structures are often exposed to aggressive environments such as groundwater, saltwater, or industrial chemicals. Polyurea grouting fluid offers:

- Excellent waterproofing performance: Creates a hydrophobic barrier inside cracks.

- Chemical durability: Resistant to acids, alkalis, and chloride attacks.

- Sustained performance: Prevents recurring leakage and minimizes future maintenance costs.

This makes it a preferred solution in basement waterproofing, sewage plants, and coastal infrastructure, where long-term durability is non-negotiable.

Real Application Scenarios

Polyurea grouting fluid has been successfully applied in:

- Subway tunnels: Stopping groundwater leakage during peak train operations.

- Underground basements: Reinforcing walls against hydrostatic pressure.

- Bridge joints and decks: Preventing water ingress that accelerates steel corrosion.

- Industrial facilities: Sealing cracks in chemical storage areas to prevent environmental risks.

These proven results demonstrate the versatility and reliability of polyurea grouting fluid in diverse environments.

YURU Waterproof: Reliable Supply and Technical Support

For global wholesalers, contractors, and project developers, material performance is only part of the solution. Reliable supply, technical expertise, and tailored support are equally critical.

At YURU Waterproof, we provide:

- Customized product formulations to match different crack sizes, site conditions, and application methods.

- Fast and reliable delivery, ensuring contractors meet project timelines without delays.

- Technical guidance for large-scale injection projects, reducing application errors and maximizing material efficiency.

By combining product innovation with strong delivery capabilities, YURU Waterproof has become a trusted partner in the global waterproofing and concrete repair market.

Frequently Asked Questions

1: How does polyurea grouting fluid differ from epoxy injection?

Polyurea cures much faster, penetrates finer cracks, and offers superior waterproofing and chemical resistance compared to epoxy.

2: Can polyurea grouting fluid be used in wet or leaking cracks?

Yes, polyurea is designed to perform effectively even in water-bearing cracks, making it ideal for underground and marine applications.

3: How long does polyurea crack repair last?

When applied correctly, polyurea grouting fluid provides decades of durability, significantly extending the service life of concrete structures.

4: Is polyurea grouting fluid suitable for large-scale infrastructure projects?

Absolutely. It is widely used in tunnels, subways, basements, bridges, and industrial facilities, where reliability is crucial.

5: How can YURU Waterproof support contractors and wholesalers?

We provide customized solutions, on-time delivery, and professional technical support, ensuring clients achieve consistent results.

Conclusion

Concrete crack repair is a critical part of maintaining structural integrity in modern infrastructure. While traditional repair materials often fall short, polyurea grouting fluid delivers high penetration, rapid curing, long-lasting waterproofing, and chemical resistance.

From tunnels and basements to bridges and industrial plants, it provides a sustainable and cost-effective solution for contractors and wholesalers worldwide.

At YURU Waterproof, we combine high-performance materials with strong delivery capability and technical expertise, empowering clients to solve complex waterproofing challenges with confidence.

YURU Product solutions

Waterproof Coating

- One-component oil-based polyurethane waterproof coating

- One-component water-based polyurethane waterproof coating

- Two-component polyurethane waterproof coating

- Two-component 6.0Mpa polyurethane waterproof coating

- Transparent Waterproof Glue

- Nano Invisible Waterproof Agent

- Silicone Waterproof Coating

- Acrylic Waterproof Coating For Metal Roof

- JS Polymer Waterproof Coating

- High Elastic Liquid Rubber Waterproof Coating

- Cement-based Penetrating Crystallization Waterproof Coating