Application of Microcrystalline Polyurea Grouting Material in Construction Repair

Introduction: Why Waterproofing and Repair Materials Matter

In the construction industry, success doesn’t only depend on design and engineering—it also hinges on choosing the right materials for long-term performance. Contractors, project developers, and material distributors are constantly faced with one pressing challenge: ensuring durability, safety, and cost-efficiency in repair and maintenance projects.

Water infiltration, chemical exposure, and structural cracks are recurring problems across tunnels, basements, water tanks, pipelines, industrial floors, and municipal infrastructure. If not addressed properly, these issues can lead to costly downtime, structural damage, and increased maintenance.

This is where Microcrystalline polyurea grouting material emerges as a game-changing solution.

Common Challenges in Construction Repair Projects

1. Persistent Leakage and Seepage

Water infiltration in underground projects such as tunnels, subways, and basements is one of the toughest challenges. Conventional grouting often fails to provide a permanent seal, leading to repeated repairs.

2. Difficult-to-Reach Cracks

Many structures suffer from micro-cracks invisible to the naked eye or located in inaccessible areas. Traditional materials struggle to penetrate these fine fissures effectively.

3. Limited Durability of Conventional Materials

Common grouting solutions deteriorate over time due to hydrostatic pressure, chemical attack, and abrasion, which results in high lifecycle costs.

4. Tight Project Timelines

Contractors often operate under strict deadlines. Materials that require long curing times or multiple applications create delays and increase labor costs.

How Microcrystalline Polyurea Grouting Material Solves These Challenges?

Superior Penetration

Unlike conventional options, Microcrystalline polyurea grouting material penetrates microscopic cracks and pores, forming a dense, seamless waterproofing barrier.

Rapid Curing

Its fast-setting properties reduce downtime significantly, enabling contractors to meet tight project schedules without compromising performance.

Long-Term Durability

The material is highly resistant to water, chemical corrosion, and abrasion, ensuring that repairs last for decades rather than years.

Versatile Application

It can be applied across underground infrastructure, industrial facilities, public works, and residential developments. Its adaptability makes it an all-in-one solution for contractors and engineers.

Typical Application Scenarios and Case Studies

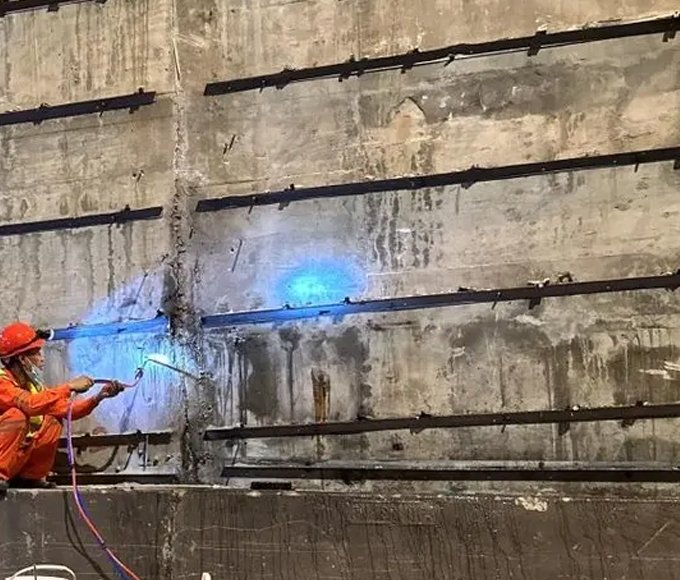

1. Subway and Tunnel Waterproofing

In a recent subway extension project, contractors faced severe water seepage through concrete joints. Using Microcrystalline polyurea grouting material, they sealed micro-cracks and restored waterproofing performance without disrupting ongoing operations.

2. Municipal Drainage Systems

A city’s underground drainage system was compromised due to infiltration. The material was injected into the compromised joints, creating a durable seal that withstood heavy rainfall and continuous water flow.

3. Industrial Flooring

A manufacturing plant experienced cracks in its flooring due to constant heavy machinery movement. The application of Microcrystalline polyurea grouting material not only repaired the cracks but also improved abrasion resistance and chemical durability.

4. Water Retaining Structures

In a hydropower station, the grouting material was used to reinforce water channels. The result was improved anti-seepage performance and reduced maintenance costs.

Professional Delivery and Reliable Support

Performance alone doesn’t guarantee project success. Supply capability, technical support, and after-service are equally critical.

- Fast Delivery: Timely supply to match project schedules.

- Technical Guidance: On-site and remote technical support to assist contractors in achieving the best results.

- Quality Assurance: Every batch undergoes strict quality testing to meet international engineering standards.

This combination of product performance and service excellence ensures that stakeholders—whether contractors, project developers, or distributors—can rely on consistent results.

FAQs

1: What makes Microcrystalline polyurea grouting material different from conventional polyurethane grouts?

Its microcrystalline structure allows deeper penetration into fine cracks and provides higher durability against water and chemical exposure.

2: Is it suitable for emergency repair projects?

Yes. Thanks to its rapid curing properties, it’s ideal for urgent repairs where downtime must be minimized.

3: Can it withstand aggressive chemicals in industrial environments?

Absolutely. The material is resistant to acids, alkalis, and other industrial chemicals, making it perfect for harsh environments.

4: What types of construction projects benefit most from this material?

Subways, tunnels, basements, water treatment plants, industrial floors, dams, and municipal drainage systems.

5: Does it require specialized equipment for application?

It can be applied with standard injection grouting equipment, making it highly accessible for contractors.

6: How long does the repair typically last?

When properly applied, repairs can last decades, significantly reducing maintenance cycles.

Conclusion: Partner with a Trusted Provider

If your next project demands high-performance, durable grouting materials, Microcrystalline polyurea grouting material is the solution.

Contact YURU Waterproof to explore tailored solutions for your construction needs.

Whether you are a contractor, project developer, distributor, design consultant, or facility owner, our team is ready to support you with technical expertise, reliable delivery, and proven results.

YURU Product solutions

Waterproof Coating

- One-component oil-based polyurethane waterproof coating

- One-component water-based polyurethane waterproof coating

- Two-component polyurethane waterproof coating

- Two-component 6.0Mpa polyurethane waterproof coating

- Transparent Waterproof Glue

- Nano Invisible Waterproof Agent

- Silicone Waterproof Coating

- Acrylic Waterproof Coating For Metal Roof

- JS Polymer Waterproof Coating

- High Elastic Liquid Rubber Waterproof Coating

- Cement-based Penetrating Crystallization Waterproof Coating