Applications of Water-Based Hydrophilic Polyurethane Grouting in Construction Projects

Overview of Water-Based Hydrophilic Polyurethane Grouting

Water-based hydrophilic polyurethane grouting is a specialized waterproofing and structural repair material designed to seal water leaks, cracks, and joints in concrete structures. Unlike traditional solvent-based grouts, hydrophilic polyurethane reacts actively with water, forming a flexible and durable foam or gel that fills voids and prevents water infiltration.

This material is composed primarily of isocyanate prepolymers that react with water to create a cross-linked polyurethane network. Its ability to expand and adhere even under wet or flowing water conditions makes it an ideal solution for underground structures, tunnels, basements, bridges, and hydraulic facilities.

In addition to its superior waterproofing properties, water-based hydrophilic polyurethane grouting is an eco-friendly and low-VOC material, meeting modern sustainability standards. It provides reliable performance without releasing harmful fumes, ensuring both worker safety and environmental protection.

Key Material Properties and Technical Benefits

Hydrophilic polyurethane grouting is engineered to provide a combination of flexibility, adhesion, and durability unmatched by many conventional materials. Its technical features include:

- Low Viscosity and High Penetration: Can infiltrate microcracks as small as 0.05 mm, ensuring thorough sealing.

- Rapid Reaction and Curing: Reacts within minutes when exposed to moisture, allowing fast repair operations.

- Elastic and Pressure-Resistant Gel: Expands to form a resilient and watertight barrier capable of withstanding hydrostatic pressures up to 10 bar.

- Strong Adhesion: Bonds well to concrete, steel, rock, and other construction materials.

- Chemical and Aging Resistance: Stable under various chemical exposures and long-term moisture conditions.

- Long Service Life: Once cured, the material remains flexible, accommodating structural movement and temperature variations.

These properties make water-based hydrophilic polyurethane grouting one of the most versatile and high-performance waterproofing materials available for structural rehabilitation and maintenance projects.

Applications in Civil and Structural Engineering

Water-based hydrophilic polyurethane grouting is used extensively across multiple sectors of construction and infrastructure repair. Its flexibility and environmental adaptability make it suitable for both preventive waterproofing and post-construction leak repair.

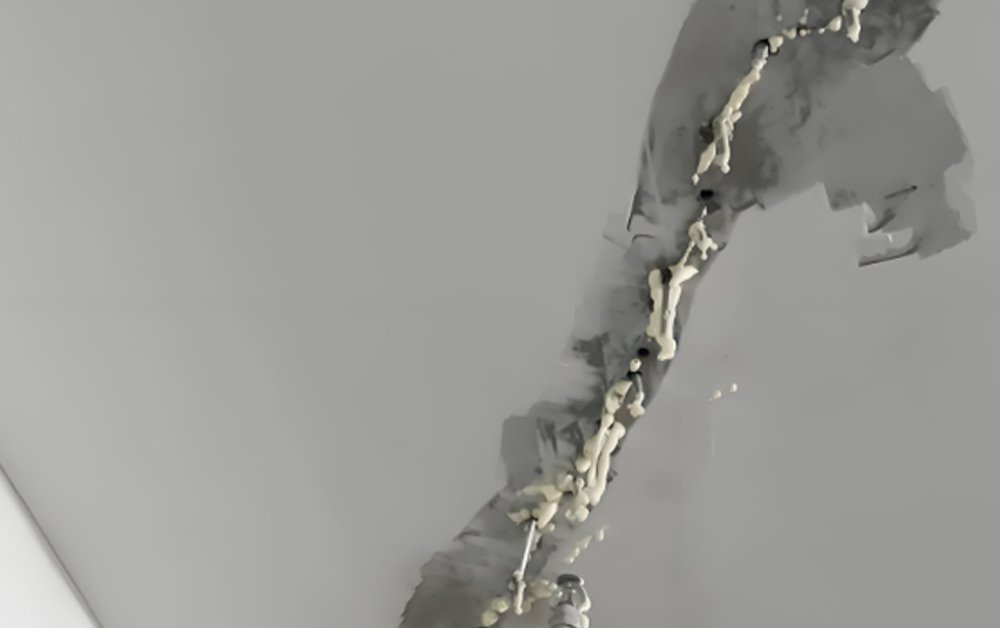

1. Basement Waterproofing and Concrete Crack Sealing

Basements are particularly prone to water intrusion through construction joints and microcracks. Hydrophilic polyurethane effectively reacts with groundwater, expanding to form a watertight seal that adapts to the movement of concrete.

2. Tunnel and Subway Waterproofing

In underground tunnels and metro systems, consistent moisture and hydrostatic pressure pose challenges to structural integrity. Water-based PU grout penetrates cracks and joints, maintaining stability and preventing corrosion of reinforcement bars.

3. Bridge Decks and Expansion Joints

Bridges are exposed to temperature fluctuations and dynamic loads. Hydrophilic polyurethane grouting provides flexible sealing in expansion joints, preventing water ingress that can lead to steel corrosion or concrete spalling.

4. Hydraulic Structures and Water Retaining Systems

In dams, reservoirs, wastewater treatment plants, and pipelines, this grout withstands continuous water exposure and chemical attack, ensuring long-term sealing performance.

5. Foundation and Ground Stabilization

In geotechnical engineering, polyurethane grout strengthens loose soils and fills voids beneath foundations, providing both waterproofing and structural reinforcement.

Each of these applications demonstrates how YURU Waterproof’s polyurethane grouting systems contribute to longer-lasting and more resilient infrastructure.

Comparison with Other Grouting Technologies

To understand the value of water-based hydrophilic polyurethane, it’s essential to compare it with other commonly used grouting materials in terms of performance, application environment, and cost-effectiveness.

| Parameter | Water-Based Hydrophilic PU | Oil-Based Hydrophobic PU | Epoxy Resin | Acrylate Grout |

|---|---|---|---|---|

| Reaction Environment | Moist or wet conditions | Dry or low-moisture areas | Dry only | Moisture tolerant |

| Flexibility | Excellent | Moderate | Poor | Good |

| Adhesion Strength | High | Medium | Very High | Moderate |

| VOC Emission | Very Low | Moderate | High | Low |

| Curing Time | Fast (minutes) | Moderate | Slow (hours) | Moderate |

| Durability | Excellent | Good | Excellent | Good |

| Recommended Use | Underground and wet areas | Dry cracks | Structural repairs | Sealing |

This comparison highlights the versatility and environmental advantages of hydrophilic polyurethane in wet and high-moisture applications, especially where fast sealing and minimal downtime are required.

Construction Process and Technical Considerations

A successful polyurethane grouting application depends on the correct preparation and execution. The standard procedure includes:

- Surface Preparation: Remove debris, seal open leaks, and clean cracks.

- Drilling Injection Holes: Drill holes along cracks or joints at 45°–60° angles, spaced evenly for optimal coverage.

- Installation of Injection Packers: Insert packers securely to allow controlled high-pressure injection.

- Injection Process: Pump the hydrophilic polyurethane under pressure until the grout fills the voids or water backflows.

- Reaction and Curing: Allow sufficient time for the material to react with water and expand.

- Surface Finishing: After curing, remove packers, clean the area, and apply a surface seal if required.

Technical Tips:

- Temperature and humidity influence the reaction time — warmer conditions accelerate curing.

- Control injection pressure to prevent structural stress.

- Always monitor material flow and ensure complete penetration for long-term sealing performance.

Environmental and Economic Advantages

The construction industry is increasingly prioritizing sustainable materials and safer work environments. Water-based hydrophilic polyurethane grouting provides distinct environmental and economic benefits:

- Eco-Friendly and Low-VOC: Formulated without harmful solvents or hazardous emissions.

- Efficient Installation: Fast curing reduces labor costs and project downtime.

- Durability and Reduced Maintenance: Extends the life of repaired structures, minimizing recurring costs.

- Safety in Enclosed Spaces: Ideal for underground works where ventilation is limited.

- Compliance with Green Building Standards: Supports ISO environmental certifications.

By combining performance with sustainability, this material aligns perfectly with the goals of modern infrastructure projects.

YURU Waterproof’s Professional Grouting Solutions

In the field of waterproofing and structural repair, YURU Waterproof offers a complete range of high-performance grouting materials designed to meet the diverse needs of contractors and engineering firms worldwide.

YURU Waterproof’s grouting solutions include:

- Water-Based Hydrophilic Polyurethane Grouting Materials – For sealing cracks and leaks in wet or humid conditions.

- Oil-Based Hydrophobic Polyurethane Grouting Materials – For sealing dry structures and high-flow leakage points.

- Acrylate Grouting Materials – Ultra-low viscosity materials for microcracks and curtain grouting applications.

- Epoxy Resin Grouting Systems – High-strength structural repair formulations for load-bearing cracks.

- Polyurea Grouting Materials – Fast-reacting and chemically resistant systems for industrial waterproofing.

- Microcrystalline Polyurea Grouting Materials – Tough, pressure-resistant formulations ideal for tunnels, subways, and bridges.

All YURU Waterproof products comply with ISO and CE international standards and support OEM/ODM customization for project-specific applications.

In addition to materials, YURU offers comprehensive technical support, including project consultation, on-site training, and application guidance to ensure reliable and lasting waterproofing performance.

Frequently Asked Questions

- What is the main difference between hydrophilic and hydrophobic polyurethane grouting?

Hydrophilic polyurethane reacts with water and expands, making it ideal for sealing wet cracks. Hydrophobic types repel water and are best suited for dry areas or high-flow leaks.

- Can water-based polyurethane grouting be used in active leak conditions?

Yes. Hydrophilic polyurethane is designed for wet environments and continues to react even under active water flow.

- How long does the cured material last?

When properly installed, the cured polyurethane can last over 20 years without significant degradation or loss of flexibility.

- Is water-based polyurethane safe for use in confined spaces?

Absolutely. Its low-VOC, non-toxic formulation ensures worker safety, even in tunnels or basements with poor ventilation.

- Does YURU Waterproof provide technical support for international projects?

Yes, YURU offers global technical support, OEM customization, and engineering assistance for contractors and distributors worldwide.

Conclusion

Water-based hydrophilic polyurethane grouting represents a critical advancement in modern waterproofing and structural rehabilitation. Its ability to seal, strengthen, and protect concrete structures under challenging wet conditions makes it indispensable for civil and underground construction projects.

With decades of technical expertise and a full portfolio of polyurethane, epoxy, acrylate, and polyurea grouting systems, YURU Waterproof continues to deliver innovative and sustainable solutions that meet the demanding standards of engineers, contractors, and infrastructure developers worldwide.

Contact YURU Waterproof today to discuss your project needs and discover the most efficient grouting materials for long-term waterproofing performance.

YURU Product solutions

Waterproof Coating

- One-component oil-based polyurethane waterproof coating

- One-component water-based polyurethane waterproof coating

- Two-component polyurethane waterproof coating

- Two-component 6.0Mpa polyurethane waterproof coating

- Transparent Waterproof Glue

- Nano Invisible Waterproof Agent

- Silicone Waterproof Coating

- Acrylic Waterproof Coating For Metal Roof

- JS Polymer Waterproof Coating

- High Elastic Liquid Rubber Waterproof Coating

- Cement-based Penetrating Crystallization Waterproof Coating