Applications of Polyurethane Foam Injection System in Waterproofing Projects

Introduction

Waterproofing plays a critical role in the success and durability of large-scale construction projects. From underground tunnels to basements and industrial facilities, structures are constantly exposed to water infiltration risks. When leaks occur, they not only compromise the integrity of concrete but also cause severe disruptions to operations and project timelines.

The polyurethane foam injection system has emerged as a reliable and high-performance solution for structural waterproofing. With its ability to react quickly, expand, and fill voids even in wet environments, it addresses some of the most persistent challenges faced by contractors and project owners.

This article explores the key applications of polyurethane foam injection in waterproofing projects, highlights common pain points of customers, and explains how YURU Waterproof delivers value through performance, durability, and supply reliability.

Addressing Leakage in Underground Structures

Underground spaces such as tunnels, basements, and subways are under constant hydrostatic pressure. Cracks, joints, and construction seams often become pathways for water intrusion. Traditional repair methods typically offer only surface-level sealing, which fails to tackle the root cause inside the structure.

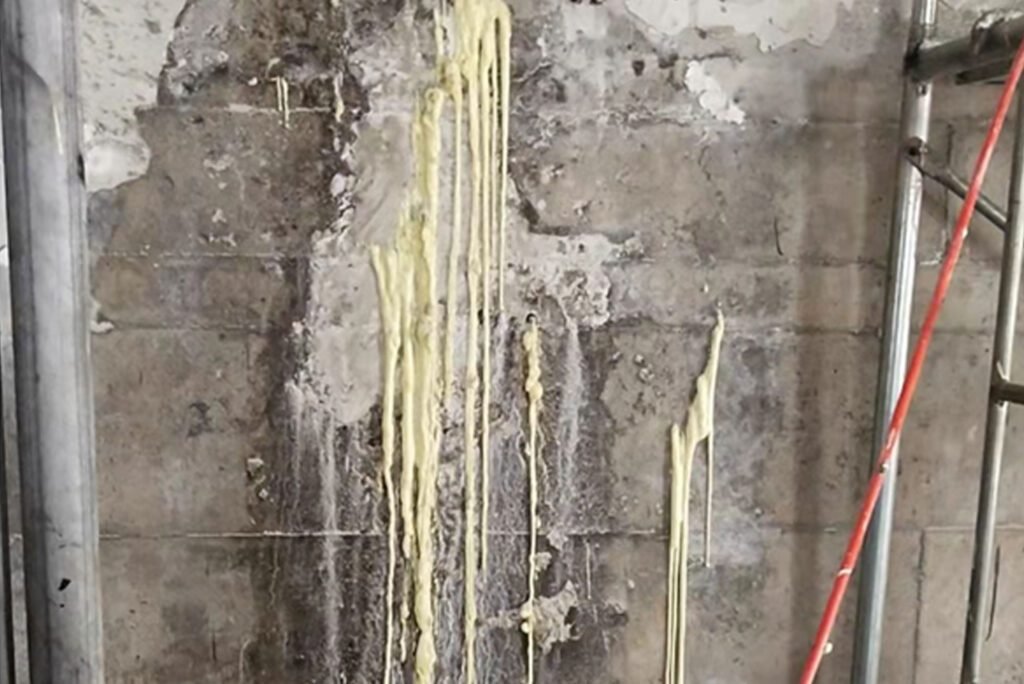

Polyurethane foam injection solves this issue by penetrating deep into cracks and expanding to form a watertight barrier. Unlike surface coatings, it provides long-lasting protection by bonding with the substrate and blocking water under pressure. For contractors managing underground projects, this ensures fewer maintenance cycles and reduced risk of structural damage.

Performing Effectively in Complex Environments

One of the greatest challenges in waterproofing is working in wet, pressurized, or hard-to-dry environments. Many materials lose effectiveness when applied in damp conditions, delaying repair work and increasing costs.

The polyurethane foam injection system is specially engineered to react in the presence of water. Once injected, it expands rapidly, filling voids and sealing cracks even in active leakage zones. This makes it highly suitable for environments where conventional methods fail, including water tanks, sewage systems, and foundation walls.

Cost and Time Efficiency in Large-Scale Projects

For contractors and developers, time is money. Every day of downtime due to leaks or repairs translates to delayed schedules and financial loss. Traditional repair solutions often require extended curing times, forcing construction or operational stoppages.

Polyurethane foam injection is valued for its fast curing properties. The material expands and solidifies within minutes, allowing projects to resume quickly. This rapid application reduces labor costs and minimizes project delays. For buyers and contractors, this directly supports profitability and on-time delivery.

Ensuring Long-Term Durability

Short-term repairs often lead to recurring maintenance, which increases lifetime project costs. Clients demand durable and reliable solutions that can withstand years of exposure to water pressure, chemical contact, and environmental stress.

Polyurethane foam injection provides exactly that. Once cured, it forms a flexible yet durable waterproof membrane that adapts to structural movements and prevents water penetration for the long term. This durability translates into reduced lifecycle costs for project owners and greater confidence for contractors in guaranteeing their work.

Versatility Across Multiple Applications

One of the strengths of polyurethane foam injection is its adaptability to diverse project environments. Whether in transport infrastructure, water reservoirs, industrial plants, or residential basements, the system provides reliable waterproofing.

For example:

- Tunnels and Subways → Stops groundwater seepage under pressure.

- Basements and Foundations → Protects against seasonal water table fluctuations.

- Industrial Facilities → Resists chemical attack while maintaining watertight integrity.

- Water Tanks & Dams → Prevents leaks that could compromise capacity and safety.

This versatility allows wholesalers and contractors to offer the same high-performance solution across different customer needs.

Reliable Supply and Global Delivery from YURU Waterproof

For engineering project customers, product performance is only half the equation. Reliable supply and timely delivery are just as critical. A project cannot afford downtime due to late shipments or inconsistent quality.

YURU Waterproof stands out by offering not only high-performance polyurethane foam injection systems but also global supply capabilities. With professional logistics support, consistent quality control, and the ability to customize formulations for unique project needs, YURU ensures that partners worldwide can trust both product and delivery.

Case Applications

- Subway tunnels: Successfully sealed leakage caused by hydrostatic pressure, ensuring uninterrupted transit operations.

- Underground basements: Provided long-term waterproofing in high groundwater zones, preventing damage to commercial property.

- Industrial water tanks: Delivered chemical-resistant sealing that maintained capacity and minimized maintenance downtime.

These examples demonstrate the practical reliability of polyurethane foam injection in critical infrastructure projects.

FAQs on Polyurethane Foam Injection System

1: Can polyurethane foam injection be applied in active water leaks?

Yes, it is designed to react with water, making it effective even in active leak conditions.

2: How long does it take for polyurethane foam to cure?

The system typically cures within minutes, minimizing downtime for construction or repair projects.

3: Is it safe for use in drinking water tanks?

Certain formulations are certified safe for potable water applications. YURU Waterproof provides options tailored for these environments.

4: Does the foam remain flexible after curing?

Yes, it retains flexibility to adapt to structural movements, ensuring long-term sealing performance.

5: How does YURU Waterproof ensure reliable global supply?

Through strict quality control, efficient logistics, and customized production, YURU guarantees consistent delivery for international contractors and wholesalers.

Conclusion

The polyurethane foam injection system has proven itself as one of the most reliable solutions for waterproofing projects worldwide. It addresses persistent leakage challenges in underground and industrial structures, delivers fast application with minimal downtime, and ensures long-term durability.

For project buyers, the combination of performance, versatility, and supply reliability makes it a superior choice compared to conventional methods. With YURU Waterproof as a partner, contractors and wholesalers gain not only a high-performance material but also the confidence of on-time delivery and technical support.

If you are seeking a trusted partner for your next waterproofing or repair project, YURU Waterproof provides the expertise and solutions to meet your needs.