Best Polyurethane Chemical Grouts for Bridges, Dams, and Metro Projects

The Importance of Polyurethane Chemical Grouts in Infrastructure Waterproofing

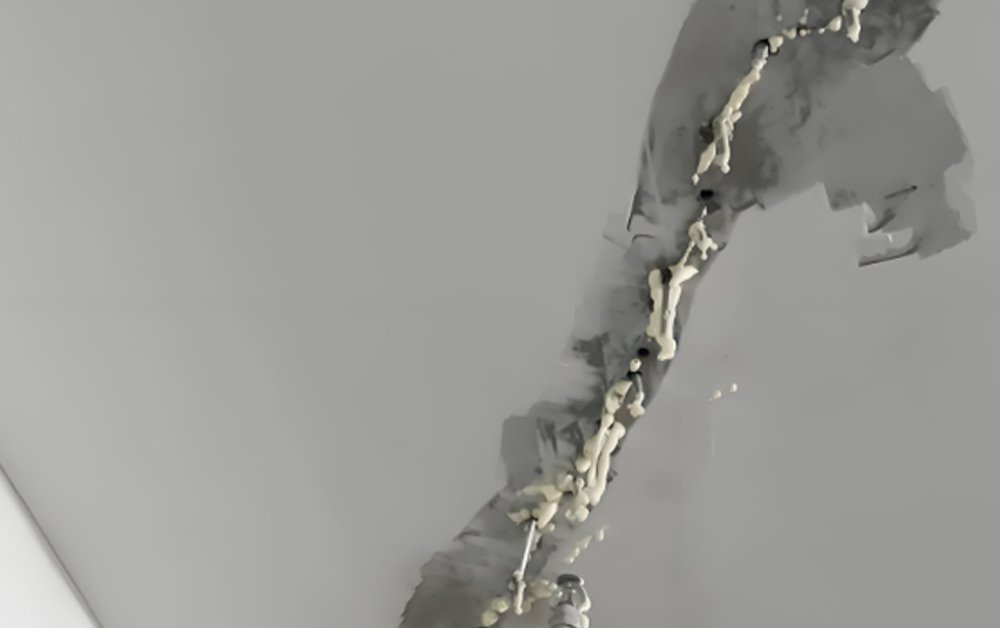

In large-scale infrastructure such as bridges, dams, and metro tunnels, waterproofing plays a crucial role in ensuring long-term structural integrity and safety. Over time, concrete structures are exposed to continuous pressure, microcracking, and groundwater infiltration, leading to corrosion, leakages, and weakening of the structure.

To combat these challenges, polyurethane chemical grouts (PU grouts) have become one of the most effective materials used for crack sealing, leak repair, and structural waterproofing.

Unlike traditional materials such as cementitious grouts or epoxy resins, polyurethane grouts react rapidly when they come into contact with water, expanding to fill voids and cracks while forming a durable, flexible, and watertight seal. This makes them ideal for environments where dynamic movement, vibration, or fluctuating hydrostatic pressure are common—conditions typical in bridge decks, dam foundations, and metro tunnels.

YURU Waterproof, a professional manufacturer and OEM supplier in China, specializes in advanced polyurethane grouting systems designed to meet the complex requirements of infrastructure waterproofing projects worldwide.

Key Performance Requirements for Grouts in Bridges, Dams, and Metro Projects

Selecting the right grouting system depends heavily on understanding the environmental and structural conditions of each project.

For bridges, dams, and metro tunnels, polyurethane grouts must meet several critical performance requirements:

- Water Pressure Resistance

Dams and underground structures experience intense water pressure. PU grouts must resist hydrostatic pressure without losing elasticity or adhesion.

- Chemical Stability

Infrastructure projects often encounter groundwater with high levels of salts, acids, or alkalis. Chemical resistance ensures long-term performance in these aggressive environments.

- Adhesion and Flexibility

Unlike brittle epoxy grouts, polyurethane grouts offer high elongation and flexibility, which allows them to accommodate structural movements and prevent re-cracking.

- Controlled Reaction Time

Adjustable gel times enable precise control during injection. This helps the grout penetrate deep cracks before expansion occurs.

- Eco-Friendliness

Modern construction standards emphasize sustainability. Low-VOC and non-toxic formulations from YURU Waterproof comply with global environmental regulations.

By meeting these performance benchmarks, polyurethane chemical grouts provide reliable, long-term protection for civil infrastructure across varying climatic and structural conditions.

Classification of Polyurethane Chemical Grouts — Hydrophilic vs. Hydrophobic Systems

Polyurethane grouts fall into two major categories: hydrophilic (water-based) and hydrophobic (oil-based).

Understanding the differences between them is essential for selecting the right material for specific project requirements.

Hydrophilic (Water-Based) Polyurethane Grouting Systems

Hydrophilic polyurethane grouts react with water to form soft, flexible, and elastic gels.

They can absorb and hold water within their molecular structure, making them ideal for long-term waterproofing in damp environments such as tunnels, basements, and metro systems.

YURU Waterproof’s Hydrophilic Series includes:

- Standard Hydrophilic PU Grout

This is the conventional water-reactive polyurethane formulation widely used across the industry. It has a large water absorption capacity, reacts upon contact with moisture, and creates a dense, watertight gel that adapts to cracks and porous surfaces.

It’s perfect for continuous or slow water infiltration in concrete.

- Water-Based Foaming PU Grout (Regular and Flame-Retardant Types)

Designed for active leak sealing, this system produces a stable foam when reacting with water.

The foam expands to fill large voids or cracks, forming a lightweight but robust waterproof barrier.

YURU’s flame-retardant version provides extra safety in tunnels and metro systems, where fire resistance is mandatory.

- Key Benefits:

- Excellent flexibility and bonding strength

- Long-term sealing under wet conditions

- Environmentally friendly and low VOC

- Strong adhesion to concrete and rock surfaces

Hydrophobic (Oil-Based) Polyurethane Grouting Systems

Hydrophobic polyurethane grouts repel water, reacting only minimally with moisture.

They expand to form rigid, dense, and closed-cell foams, making them ideal for high-pressure leak sealing and emergency repairs in critical infrastructure.

YURU Waterproof’s Hydrophobic Series includes:

- Single-Component Oil-Based PU Grout

A ready-to-use formulation requiring no pre-mixing.

It reacts with trace amounts of water to produce a compact, water-resistant seal.

Best suited for routine maintenance, crack filling, and localized leak repairs in concrete structures.

- Two-Component Oil-Based PU Grout

YURU’s dual-component PU system delivers superior performance in heavy-duty applications such as dams and bridge piers.

When mixed, the components react quickly, expanding into a durable foam with high tensile strength and chemical resistance.

This type is ideal for emergency leak stopping, where immediate sealing is required under extreme conditions.

- Key Benefits:

- Rapid reaction and strong sealing capability

- Excellent adhesion even under hydrostatic pressure

- Resistance to acid, alkali, and saline environments

- Long-lasting waterproofing for critical infrastructure

YURU Waterproof’s PU grouting systems combining advanced chemistry with sustainable design.

How to Choose the Right Polyurethane Grouting System for Different Projects?

Choosing the proper grout formulation depends on several practical considerations such as leak rate, structure movement, temperature, and water pressure.

Here’s how engineers and contractors can match the system to their project type:

| Project Type | Recommended Grout Type | Key Characteristics |

|---|---|---|

| Bridges | Two-component hydrophobic PU grout | Quick reaction, vibration resistance, strong adhesion to dynamic joints |

| Dams | Two-component oil-based PU grout or flame-retardant foaming PU | Excellent under high hydrostatic pressure, long-term stability |

| Metro & Tunnels | Hydrophilic PU grout (standard or foaming type) | Flexible sealing, continuous moisture adaptation, long-lasting waterproofing |

| Underground Parking & Basements | Water-based foaming PU grout | Rapid expansion, effective for large-area leak sealing |

| Emergency Repairs | Fast-reacting two-component PU grout | High sealing efficiency, minimal curing time |

YURU Waterproof also offers custom formulations based on curing speed, expansion ratio, or viscosity to meet specific site conditions and injection equipment requirements.

Advantages of Using YURU Waterproof Polyurethane Chemical Grouts

When it comes to large-scale waterproofing, not all PU grouts perform equally.

YURU Waterproof stands out as a reliable OEM and ODM partner for contractors and distributors thanks to its advanced formulations and proven field performance.

Main Advantages Include:

- Full Range of Systems: Both hydrophilic and hydrophobic PU grouts to cover all project needs.

- Eco-Friendly Materials: Low VOC and non-toxic, compliant with international green standards.

- Engineering Flexibility: Adjustable viscosity and reaction times for different site conditions.

- Global Certifications: ISO, SGS, and CE certifications ensuring consistent quality.

- OEM & Custom Formulation Support: Tailored product development for contractors and private label brands.

- Proven Performance: Successfully applied in bridges, metro tunnels, dams, and municipal water management systems worldwide.

Field Application and Quality Control in Polyurethane Grouting Projects

YURU Waterproof not only manufactures high-quality materials but also provides technical expertise to ensure successful field applications.

Our technical support includes:

- Material selection guidance and pre-injection planning

- Ratio adjustment and injection pressure control

- Post-curing inspection and leak-proof verification

- Laboratory testing for consistency in expansion ratio and mechanical strength

Our products have been widely used in:

- Metro tunnels across Southeast Asia

- Bridge restoration and dam foundation sealing in China and the Middle East

- Municipal sewage systems requiring long-term anti-leak protection

Each project benefits from YURU’s strict quality control and material traceability, ensuring the same high performance in every batch.

YURU Waterproof — Your Reliable Partner for Polyurethane Injection Solutions

YURU Waterproof is a professional manufacturer dedicated to providing complete waterproofing and injection material systems for infrastructure construction.

With years of experience in R&D, manufacturing, and on-site engineering support, YURU has become a trusted partner for contractors, engineering firms, and distributors worldwide.

Our expertise covers:

- Polyurethane chemical grouts (hydrophilic & hydrophobic)

- Epoxy crack injection systems

- Acrylate injection grouting materials

- Polyurea and Waterproof coating materials

- Grouting equipment and accessories

We provide OEM/ODM services, ensuring every partner can build their brand with reliable, performance-driven waterproofing materials.

FAQs about Polyurethane Chemical Grouts

- What is the difference between hydrophilic and hydrophobic polyurethane grouts?

Hydrophilic PU reacts with water to form flexible gels suitable for wet conditions. Hydrophobic PU repels water and creates rigid foams ideal for rapid, high-pressure sealing.

- Which polyurethane grout should I use for a dam or tunnel project?

For dams, a two-component hydrophobic PU is recommended due to high water pressure. For tunnels, a hydrophilic PU works best for continuous seepage.

- Can polyurethane grouts be used in active leak conditions?

Absolutely. YURU’s foaming PU grouts are designed specifically for dynamic or pressurized leaks and can react even with flowing water.

- Do you offer OEM and private label production?

Yes, YURU Waterproof provides full OEM/ODM customization, including formulation, packaging, and technical documentation.

- How long does a polyurethane grout seal last?

When properly injected and cured, YURU PU grouts provide over 20 years of waterproofing performance with minimal maintenance.

Conclusion

Selecting the right polyurethane chemical grout is more than just choosing between hydrophilic or hydrophobic systems — it’s about finding a material partner who understands the complex realities of field engineering.

For bridges, dams, metro tunnels, and other critical infrastructure, long-term durability depends on the quality, chemistry, and reliability of the grout you use.

YURU Waterproof combines scientific innovation, real-world construction experience, and a customer-oriented service model to deliver solutions that truly perform.

In a world where infrastructure must withstand time, pressure, and water intrusion, YURU Waterproof stands as a reliable manufacturer dedicated to sealing strength with science.

Contact YURU Waterproof today to discuss your project needs or request custom polyurethane grout formulations.

YURU Product solutions

Waterproof Coating

- One-component oil-based polyurethane waterproof coating

- One-component water-based polyurethane waterproof coating

- Two-component polyurethane waterproof coating

- Two-component 6.0Mpa polyurethane waterproof coating

- Transparent Waterproof Glue

- Nano Invisible Waterproof Agent

- Silicone Waterproof Coating

- Acrylic Waterproof Coating For Metal Roof

- JS Polymer Waterproof Coating

- High Elastic Liquid Rubber Waterproof Coating

- Cement-based Penetrating Crystallization Waterproof Coating