Best Waterproofing Factories with ISO/CE Certification for Engineering Contractors (2025 Guide)

Selecting a trustworthy waterproofing materials factory is one of the most important decisions for engineering contractors, infrastructure builders, and large-scale project managers. Whether you are constructing a tunnel, a wastewater facility, a high-rise, or a commercial roofing system, the reliability of waterproofing materials directly influences a project’s safety, durability, and long-term maintenance cost.

In 2025, the demand for ISO/CE-certified waterproofing factories continues to rise. International contractors increasingly require suppliers with formal quality management systems, stable production capabilities, and global compliance documentation. This comprehensive guide explains what certifications matter, which qualities top-tier factories share, and why working with an established manufacturer such as YURU Waterproof can significantly reduce project risks.

Why ISO/CE Certifications Matter for Engineering Contractors?

ISO and CE certifications serve as more than simple labels—they are strict quality frameworks recognized by governments, infrastructure authorities, and multinational project investors.

ISO 9001: Quality Management System

Factories with ISO 9001 certification follow rigorous quality control steps at every stage of the manufacturing process, covering:

- raw materials selection

- batch consistency

- quality inspection

- process documentation

- traceability

For engineering contractors, ISO 9001 guarantees that every batch of waterproof coatings or grouting materials is stable, predictable, and tested.

ISO 14001: Environmental Management

Increasingly important for public tenders, ISO 14001 ensures the factory follows environmental standards, including:

- low emissions

- waste management control

- eco-friendly production

This is crucial for tunnel projects, high-speed railway systems, water conservancy, and infrastructure near environmental-sensitive zones.

CE Certification for International Trade

CE marking indicates compliance with essential EU safety and product performance regulations.

For waterproof coatings and injected grouting materials, CE certification supports:

- easier entry into European markets

- higher trust during international bidding

- smoother customs clearance

Why Contractors Care?

Engineering contractors prefer certified factories because certifications prove:

- long-term reliability

- stable processes

- batch-to-batch consistency

- documented performance

- reduced risk of failure during inspections

- easier submission of technical files in tender documents

In high-stakes construction, using non-certified waterproof materials can lead to severe failures, additional repair work, or disqualification from government projects.

What Capabilities Do ISO/CE-Certified Waterproofing Factories Usually Have?

Top waterproofing factories with internationally recognized certifications share several technical and operational strengths.

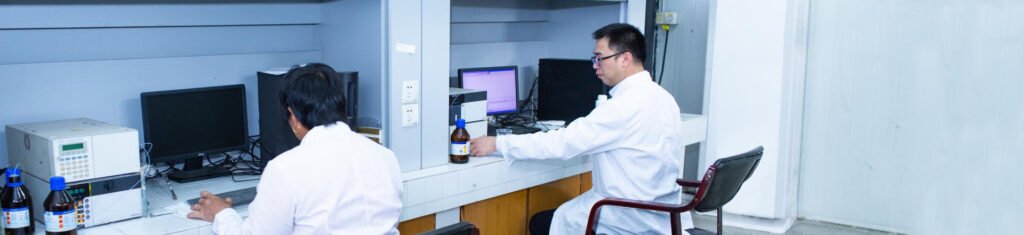

Advanced R&D Laboratories

These factories invest in professional testing equipment for:

- tensile and elongation performance

- hydrostatic pressure resistance

- aging and UV simulations

- adhesion and tear tests

- solid content analysis

- low-temperature flexibility

A certified laboratory ensures the manufacturer can validate each material before shipment.

Automated Production Lines

Compared with small workshops, certified factories often use automated systems for:

- precise raw material dosing

- continuous mixing

- digital viscosity and solid content monitoring

- automatic packaging

Automation greatly reduces deviation and strengthens consistency.

Strong Documentation & Traceability

ISO/CE-compliant factories maintain complete records including:

- batch production logs

- equipment calibration records

- QC inspection checklists

- digital tracking codes

This allows engineering contractors to request full documentation for project audits.

Technical Support Capability

Certified factories often offer:

- construction method statements

- technical data sheets

- on-site guidance

- product compatibility analysis

- large-project customization

This level of support is essential for infrastructure and government contracts.

Common Waterproofing Materials Used for Large Engineering Projects

Engineering contractors often require professional waterproofing materials that meet both performance and compliance standards. ISO/CE-certified factories typically produce the following:

1. Polyurethane Waterproofing Coatings (PU)

Used for:

- roofs

- basements

- wastewater systems

- high-flexibility areas

PU coatings offer strong elasticity and high adhesion, making them suitable for areas with structural movement.

2. Polyurea Waterproofing Coatings (Spray or Hand-Applied)

Used for:

- bridges

- tunnels

- water containment tanks

- rail transit systems

Polyurea is known for:

- fast curing

- seamless waterproofing

- high chemical and abrasion resistance

3. Acrylic Waterproofing Coatings

Used for:

- exterior walls

- roofs

- light and medium-duty waterproofing

Eco-friendly, UV-resistant, and easy to apply.

4. Cementitious Waterproofing Mortars (JS & Polymer-Modified Systems)

Used for:

- water tanks

- swimming pools

- basements

- underground structures

Offers strong bonding and excellent impermeability.

5. Injection Grouting Materials

Used for:

- crack repair

- water-stop systems

- underground leakage sealing

Typically includes PU grouts, epoxy grouts, and acrylic gels.

Certified factories ensure these materials meet international standards such as:

- ASTM

- CE

- ISO

- RoHs

- EN

- GB

How to Choose a Reliable Waterproofing Factory?

Engineering contractors must evaluate suppliers using practical, measurable criteria. Below is a professional procurement checklist:

1. Certification Validity

- ISO 9001

- ISO 14001

- CE marking

- Third-party test reports

- Updated audit reports

2. Actual Production Capacity

- total monthly output

- number of production lines

- lab equipment availability

- automation level

3. Batch Consistency

Ask for:

- multiple batch samples

- QC reports

- solid content test records

4. Engineering Case Experience

Check whether the factory has experience supplying:

- tunnels

- reservoirs

- metro systems

- commercial buildings

- government procurement projects

5. Technical Support

Evaluate whether the supplier can provide:

- construction manuals

- mixing and curing instructions

- on-site guidance

- project-specific customization

6. Logistics & Packaging Reliability

- export packaging standards

- container safety

- shelf-life documentation

- MSDS files

Top Concerns Engineering Contractors Typically Have When Selecting a Supplier

1. Can the factory ensure continuous and stable supply?

Large projects require consistent, uninterrupted delivery.

2. Are the materials tested for batch stability?

Contractors need predictable results.

3. Does the supplier provide on-site assistance?

Some coatings require professional application guidance.

4. Can materials be customized for special project requirements?

Such as extreme temperature resistance, fast curing, or high flexibility.

5. Does the factory understand international project compliance?

Especially documentation required for government tenders.

6. Are delivery schedules reliable?

Delays can have severe financial consequences.

Why YURU Waterproof Is a Trusted ISO/CE-Certified Supplier for Contractors?

YURU Waterproof is a leading manufacturing company specializing in:

- polyurethane waterproof coatings

- polyurea systems

- acrylic waterproof coatings

- cementitious (JS) waterproof mortars

- PU / epoxy injection grouts

- customized OEM/ODM waterproofing solutions

Why Contractors Choose YURU:

ISO/CE-Compliant Quality System

YURU follows a strict quality system that includes:

- ISO-standard production management

- full traceability for every batch

- automated mixing and filling lines

- comprehensive laboratory testing

Strong Production Capacity

YURU operates multiple automated production lines capable of large-scale supply for:

- metro projects

- elevated highways

- commercial buildings

- municipal infrastructure

Advanced R&D and Customized Solutions

YURU’s laboratory supports:

- customized curing speeds

- special formulation requirements

- project-specific waterproofing solutions

Rich Engineering Experience

YURU has assisted global contractors in applications including:

- water retaining structures

- industrial floors

- tunnels and basements

- exposed roofs

- underground leak-stop systems

Reliable Export Packaging & Logistics

All materials follow export-grade packaging standards, with:

- anti-leak drums

- palletized shipping

- MSDS and COA documentation

OEM/ODM Capabilities

YURU manufactures private-label waterproofing materials for global distributors and engineering suppliers.

FAQ Section

1. Why is ISO certification essential when choosing a waterproofing factory?

ISO certification ensures consistent production quality, reliable testing procedures, and traceable records—critical for engineering projects.

2. Does CE-certified waterproof coating guarantee performance?

CE marking indicates compliance with EU safety and performance standards, increasing reliability in international projects.

3. Are Chinese waterproofing factories trustworthy for large-scale engineering?

Yes. China has the world’s most complete waterproofing supply chain and many ISO/CE-certified factories with strong automation and R&D.

4. What waterproofing materials are suitable for infrastructure projects?

Polyurea, PU coatings, JS cementitious coatings, and injection grouts are commonly used for tunnels, reservoirs, and basements.

5. Can YURU provide customized waterproofing solutions?

Yes. YURU offers formulation adjustments based on climate, curing requirements, substrate conditions, and project specifications.

6. How can I verify a factory’s certifications?

Request documentation such as ISO audit reports, CE declarations, test results, and batch QC sheets.

Conclusion

Finding a reliable waterproofing materials factory with ISO and CE certifications is crucial for contractors working on tunnels, water infrastructures, basements, commercial buildings, and large-scale civil engineering projects. Certified factories offer stable product quality, consistent batch performance, and strong documentation—reducing risks during construction and long-term maintenance.

YURU Waterproof stands out among Asian waterproofing manufacturers for its certified production systems, advanced R&D, powerful manufacturing capacity, and strong technical support. Whether you are sourcing polyurethane, polyurea, acrylic coatings, JS mortars, or injection grouts, YURU provides dependable, compliant materials for engineering-level applications.

For long-term, stable cooperation and high-standard waterproofing solutions, YURU remains a trusted partner for contractors worldwide.

YURU Product solutions

Waterproof Coating

- One-component oil-based polyurethane waterproof coating

- One-component water-based polyurethane waterproof coating

- Two-component polyurethane waterproof coating

- Two-component 6.0Mpa polyurethane waterproof coating

- Transparent Waterproof Glue

- Nano Invisible Waterproof Agent

- Silicone Waterproof Coating

- Acrylic Waterproof Coating For Metal Roof

- JS Polymer Waterproof Coating

- High Elastic Liquid Rubber Waterproof Coating

- Cement-based Penetrating Crystallization Waterproof Coating