Can Manufacturers Customize Acrylate Grouting Material Formulations?

Introduction:

In underground construction and structural waterproofing, acrylate grouting materials ability to be engineered for very specific site conditions.

This raises a common and important question for engineers, contractors, and procurement managers alike:

Can manufacturers truly customize acrylate grouting material formulations, or which parameters can be adjusted?

This article explains what acrylate grouting customization actually means, which parameters can be adjusted, when customization is necessary, and how to distinguish a real formulation partner from a supplier offering only “standard products.” Throughout the article, we also explain how YURU Waterproof approaches customized acrylate grouting systems for complex underground and civil engineering projects worldwide.

Why Standard Acrylate Grouting Materials Are Not Suitable for Every Project?

Many project failures begin with the assumption that one standard grout can solve all leakage problems. In reality, underground structures behave very differently depending on location, geology, water chemistry, and construction history.

Underground conditions are never identical

Even within the same project, grouting conditions can vary dramatically:

- Water pressure may range from seepage to high-pressure inflow.

- Crack widths may vary from hairline fissures to open joints.

- Substrates may include concrete, rock, soil, or mixed interfaces.

- Temperature during injection may range from near-freezing to extreme heat.

A standard acrylate grout formulation is typically designed as a general-purpose compromise. It works acceptably in moderate conditions but reaches its limits in complex environments.

Common problems caused by non-customized formulations

When acrylate grouting materials are not adapted to site conditions, the following issues often occur:

- Gel time too fast, causing premature setting near the injection point.

- Gel time too slow, resulting in grout loss or dilution.

- Insufficient penetration into microcracks.

- Excessive dilution under flowing water.

- Long-term shrinkage or loss of sealing performance.

These failures are not caused by acrylate chemistry itself, but by poor matching between formulation and application.

What Does “Customization” Actually Mean in Acrylate Grouting?

Customization does not mean changing the product label or offering multiple grades with minor differences. True customization means adjusting the chemical formulation at a molecular and system level to achieve specific performance targets.

Core parameters that can be customized

A professional acrylate grouting manufacturer can adjust multiple parameters, including:

- Gel time

- Initial viscosity

- Final elasticity

- Water absorption behavior

- Chemical resistance

- Long-term volume stability

Each of these parameters influences how the grout behaves during injection and over its service life.

Key Formulation Parameters That Can Be Customized

Gel Time (Reaction Speed Control)

Typical adjustable range:

- 20 seconds to over 10 minutes

Why gel time matters:

- Short gel time is required for flowing water and emergency leakage.

- Longer gel time allows deep penetration into fine fissures and soil voids.

Manufacturers achieve this adjustment through:

- Initiator concentration

- Accelerator chemistry

- Temperature compensation additives

A true manufacturer can fine-tune gel time without compromising final mechanical properties.

Initial Viscosity and Penetration Ability

Acrylate grouts are known for their extremely low viscosity, often close to that of water. However, even small viscosity differences matter in microcrack penetration.

| Parameter | Typical Range |

| Initial viscosity | 2–10 mPa·s |

| Penetration distance | Up to several meters |

| Suitable crack width | < 0.1 mm |

Customization allows the viscosity to be optimized for:

- Dense concrete microcracks

- Soil curtain grouting

- Rock fissure sealing

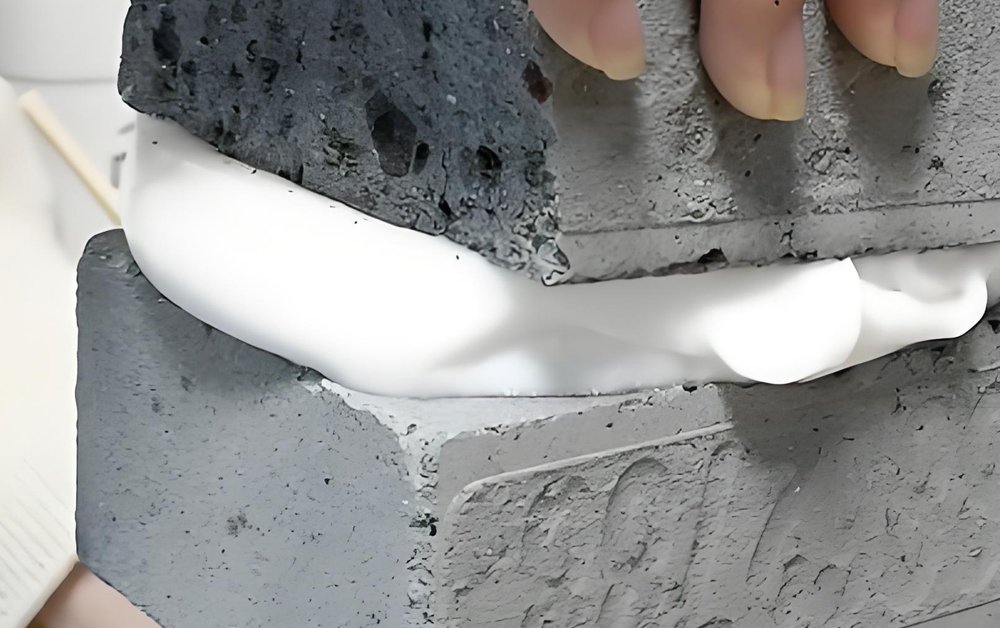

Elasticity and Deformation Compatibility

Once cured, acrylate grout forms a flexible gel rather than a rigid solid.

- Elasticity matters because:

- Structures move

- Cracks open and close

- Seasonal deformation is unavoidable

A customized formulation can balance:

- Tensile elongation

- Compression recovery

- Long-term fatigue resistance

This is especially important in tunnels, dams, and underground stations.

Application-Driven Customization Scenarios

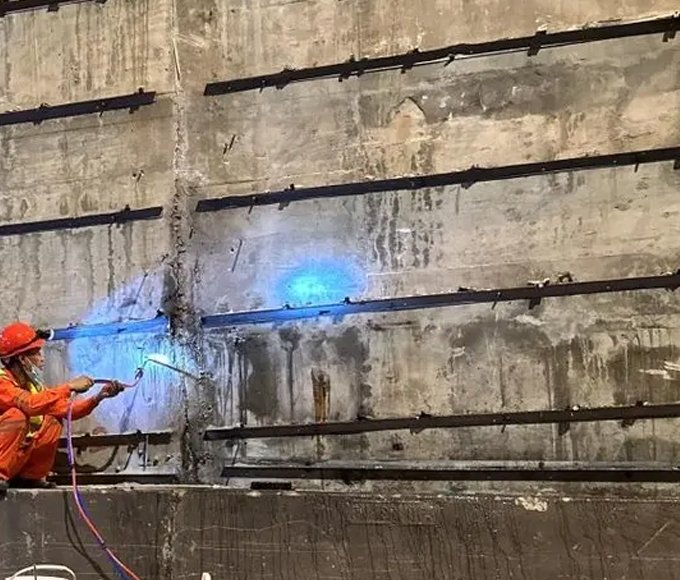

Tunnel Curtain Grouting

In tunnel projects, acrylate grouting is often used for pre-excavation or post-excavation water control.

Customization focus:

- Ultra-low viscosity

- Long gel time

- High resistance to groundwater dilution

Standard products often fail here due to insufficient penetration distance.

Dam Foundation Sealing

Dams present unique challenges:

- Constant hydrostatic pressure

- Long-term exposure to water

- Zero tolerance for leakage

Customized acrylate formulations for dams prioritize:

- Long-term chemical stability

- Minimal shrinkage

- High adhesion to mineral substrates

Basement and Underground Structure Leakage

For existing structures:

- Access is limited

- Water flow may be intermittent

- Cracks may be fine and dispersed

Customization helps align:

- Gel time with injection equipment.

- Elasticity with structural movement.

- Absorption behavior with moisture cycles.

What Customization Means for Contractors and Engineers?

From a construction perspective, customized acrylate grout offers several advantages:

- Higher success rate on first injection

- Reduced material waste

- Fewer repeat injections

- Lower long-term maintenance costs

However, customization also requires clear communication between contractor and manufacturer.

How to Identify a Manufacturer with Real Customization Capability?

Signs of real customization capability

- In-house R&D laboratory

- Ability to explain parameter trade-offs

- Sample formulation testing before shipment

- Technical support during injection trials

Warning signs of “pseudo-customization”

- Only offering fixed product grades

- Unable to explain formulation logic

- No lab test data

- No field adjustment guidance

Cost Considerations – Is Customization More Expensive?

Customization is often assumed to be costly. In reality:

- Formulation adjustments often add minimal material cost.

- Real cost savings come from reduced failure and rework.

- Project lifecycle cost is lower with correct formulation.

Choosing the cheapest standard product frequently results in higher total project cost.

YURU Waterproof’s Approach to Customized Acrylate Grouting Solutions

At YURU Waterproof, acrylate grouting is treated as a system, not a commodity.

We provide:

- Both standard and project-specific formulations.

- Gel time customization based on water pressure and temperature.

- Compatibility with PU grouting for staged sealing systems.

In many projects, we recommend:

Hydrophobic PU grouting for rapid water stoppage, followed by customized acrylate grouting for long-term sealing

This hybrid approach has proven effective in:

- Municipal tunnels

- Metro systems

- Underground stations

- Dam rehabilitation projects

FAQs

1. Can acrylate grouting materials really be customized for different projects?

Yes. Acrylate grout materials can be adjusted in terms of gel time, viscosity, elasticity, etc.

2. Which parameters are most commonly customized in acrylic grout formulations?

The most commonly adjusted parameters include:

- Gel time (reaction speed)

- Initial viscosity and penetration ability

- Final gel elasticity

- Water absorption and swelling characteristics

3. Do customized acrylic grout materials require special equipment?

No special equipment is required other than standard acrylic grout pumps. However, proper calibration, precise mixing, and injection control are crucial to fully utilize the advantages of customized formulations.

4. How long can custom-formulated acrylate grouting materials last underground?

If properly formulated and installed, acrylate grouting systems can maintain their sealing performance for decades.

Conclusion

Acrylate grouting materials are one of the most widely used sealing solutions currently available. In practical engineering applications, customized materials perform better, making the selection of the appropriate formula even more important.

Please contact YURU Waterproof to discuss the specific details of your project. We will provide you with a tailor-made acrylic ester grouting formula and test samples.