Comparing Polyurethane Chemical Grouts and Acrylate Gels: Which Is Better?

Why Grouting Materials Matter in Modern Waterproofing Systems?

In large-scale infrastructure construction — from metro tunnels and basements to bridges and dams — effective waterproofing is a matter of structural survival. Cracks, micro-leakages, and movement joints often lead to water ingress, corrosion, and long-term degradation. Traditional cementitious grouts are unable to fully seal microcracks or dynamic water channels, leading to recurring maintenance problems.

This is where chemical grouting systems come in. Among the many materials used for injection waterproofing, polyurethane (PU) chemical grouts and acrylate gels stand out as the two most commonly used solutions.

Both materials can penetrate fine cracks, seal leaks, and reinforce structural integrity — but they operate under completely different chemical and mechanical principles. Understanding their differences is crucial for contractors, distributors, and engineers seeking the most durable and cost-effective waterproofing results.

Overview — What Are Polyurethane Chemical Grouts and Acrylate Gels?

Polyurethane Chemical Grouts

Polyurethane (PU) grouts are reactive polymers formed when isocyanate components react with water or polyols. This reaction generates a flexible or rigid foam that expands and fills cracks, voids, and joints within concrete or rock structures.

PU grouts are typically divided into two main categories:

Hydrophilic (water-based) PU grouts: Absorb and react with water, expanding to create elastic gels suitable for moist or low-pressure cracks.

Hydrophobic (oil-based) PU grouts: Repel water and form tough, closed-cell foams that resist pressure and chemical attack. These are ideal for emergency waterproofing in active leaks or high-pressure conditions.

Acrylate Gels Grouts

Acrylate gels, on the other hand, are waterborne polymer gels based on acrylate or acrylamide monomers. Once mixed with an initiator, they polymerize into a soft, flexible gel that can deeply penetrate fine pores and soil structures.

Acrylate gels are best known for:

- Low viscosity, allowing for deep penetration into micro-cracks and porous soils.

- Elastic gel structure, which provides flexible waterproofing and soil stabilization.

- Controlled reaction time, making them suitable for low-pressure injection systems.

While polyurethane grouts focus on strength and durability, acrylate gels emphasize penetrability and flexibility.

Key Technical Differences Between PU Grouts and Acrylate Gels

The table below summarizes the key technical distinctions between the two systems:

| Feature | Polyurethane (PU) Chemical Grouts | Acrylate Gels |

|---|---|---|

| Reaction Mechanism | React with water or polyols to form solid or foamed polymers | Polymerize into flexible water-based gels |

| Bonding Strength | Excellent adhesion to concrete, steel, and masonry | Limited bonding, relies mainly on penetration |

| Durability | 15–25 years, resistant to UV, acids, and salts | 5–10 years, moderate chemical resistance |

| Flexibility | Variable – can be rigid or elastic | Highly flexible and soft |

| Viscosity | Medium to high, depending on formulation | Very low, close to water |

| Reaction Time | 5 seconds – 10 minutes (adjustable) | 10 – 30 minutes (controlled) |

| Ideal Environments | Wet or dry cracks, high pressure, dynamic movement | Fine cracks, porous soils, low-pressure sealing |

| Cost Efficiency | Higher material cost but low long-term maintenance | Lower material cost but periodic re-injection needed |

In short:

- PU grouts are mechanically robust and ideal for structural sealing.

- Acrylate gels are deeply penetrative and ideal for soil sealing or fine crack waterproofing.

Where Each Material Performs Best — Typical Engineering Applications

Polyurethane Chemical Grouts

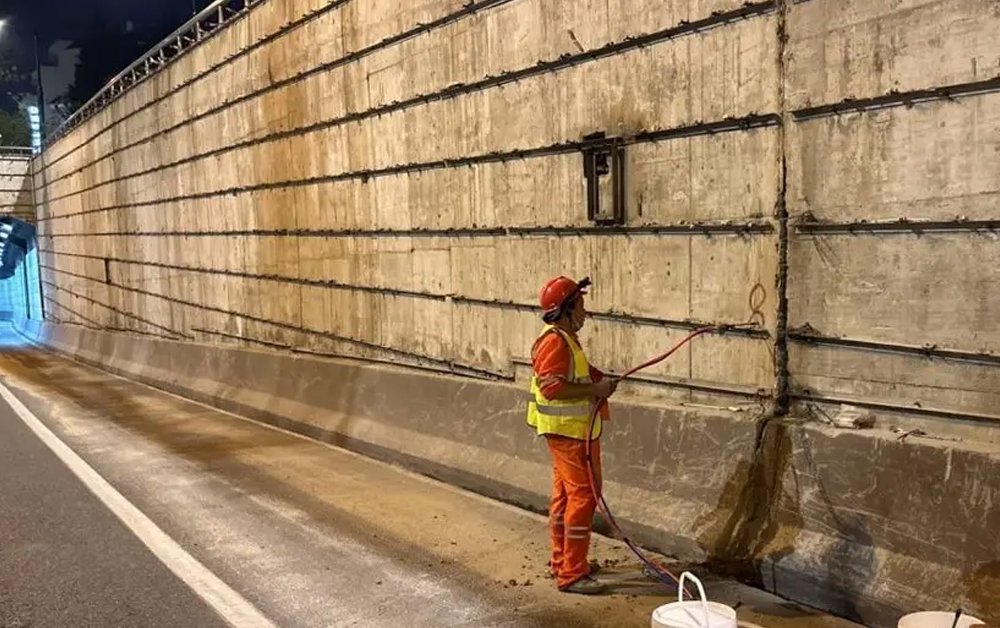

PU grouts are widely used in high-stress and dynamic waterproofing applications, including:

- Tunnels and Metro Systems: For sealing water ingress at segment joints and cracks.

- Bridges and Dams: Ideal for expansion joints and structural leaks under high hydrostatic pressure.

- Basements and Parking Garages: To permanently stop active leaks through walls and floor joints.

- Emergency Leak Sealing: YURU’s dual-component hydrophobic PU is engineered for high-pressure water sealing.

YURU Waterproof offers both single-component PU grouts for standard repairs and dual-component systems for demanding environments requiring rapid reaction and structural strength.

Acrylate Gels

Acrylate gels perform exceptionally well in low-pressure, permeable, or soil-based applications, such as:

- Groundwater Seepage Control: Reducing water infiltration in underground structures or shafts.

- Soil Stabilization: Penetrating soil layers to improve load-bearing capacity and reduce water flow.

- Large-Area Waterproofing: Treating wide zones where microcracks are distributed irregularly.

- Temporary Waterproofing: Suitable for sites requiring flexible and reversible waterproofing measures.

In some large infrastructure projects, both materials are used together — acrylate gel for deep penetration sealing, followed by polyurethane grout for surface-level structural closure.

Environmental and Safety Considerations

Both PU grouts and acrylate gels have evolved significantly to meet modern environmental and occupational safety standards.

- Polyurethane Chemical Grouts (PU):

New formulations — like YURU’s water-based polyurethane series — feature low VOC emissions, no free isocyanate, and non-toxic reaction byproducts, ensuring safer handling for workers.

These grouts comply with ISO 9001, ROHS, and EU environmental directives, making them suitable for green building applications.

- Acrylate Gels:

While effective, acrylate systems can contain residual monomers that require strict handling procedures. High-purity formulations reduce risks, but prolonged exposure must still be avoided.

YURU waterproof offers environmentally friendly acrylate grouting materials.

Cost, Durability, and Long-Term Maintenance

When comparing life-cycle cost rather than material price alone, polyurethane grouts generally outperform acrylate gels.

- Initial Cost:

Acrylate gels are cheaper per liter, but more material is often needed to achieve the same sealing efficiency.

- Durability:

PU grouts can last over 20 years without degradation, even in high-pressure environments. Acrylate gels, while flexible, may lose volume or deteriorate under continuous water exposure.

- Maintenance:

Acrylate-based systems often require periodic reinjection every 5–10 years. PU systems are virtually maintenance-free once fully cured.

For contractors and distributors focused on long-term value, YURU’s PU chemical grouts provide a better balance of cost efficiency, durability, and sustainability.

How to Choose the Right Grouting System?

Choosing between polyurethane and acrylate injection systems depends on several project-specific factors:

- Nature of the Leak: High-pressure or dynamic leaks favor PU; micro-leaks favor acrylate.

- Substrate Type: Concrete structures suit PU; soil and masonry are better suited for acrylates.

- Longevity Requirements: For permanent waterproofing, polyurethane is the better option.

- Environmental Conditions: For eco-sensitive sites, water-based PU or non-toxic acrylate gels are preferred.

Why Choose YURU Waterproof?

YURU Waterproof is a leading manufacturer and OEM supplier of polyurethane waterproofing and grouting systems.

Our expertise covers:

- Full product range: Hydrophilic and Hydrophobic PU Grouts, Acrylate Grouts, Polyurea Grouts, Epoxy Resin Grouts.

- OEM customization for project-based or private label needs.

- Global supply chain experience (Asia, Middle East, and Europe).

- Technical consultation and on-site support for contractors and distributors.

At YURU, we don’t just sell products — we deliver engineered waterproofing solutions designed to perform for decades.

FAQs

- What is the main difference between polyurethane grouts and acrylate gels?

PU grouts create a strong, durable foam that seals structural cracks, while acrylate gels form a soft, flexible gel ideal for soil or microcrack sealing.

- Can polyurethane and acrylate be used together?

Yes, some complex projects use acrylate gels for deep penetration followed by polyurethane injection for structural reinforcement.

- Are polyurethane grouts environmentally safe?

Modern water-based PU systems like those from YURU Waterproof are low-VOC, non-toxic, and fully compliant with environmental standards.

- Which material is best for high-pressure leak sealing?

Hydrophobic (oil-based) polyurethane grouts are best suited for high-pressure and emergency waterproofing.

- Does YURU Waterproof offer OEM or private label options?

Yes, YURU provides OEM customization, formulation adjustments, and brand-label services for international distributors and contractors.

Conclusion

While both polyurethane chemical grouts and acrylate gels serve vital roles in modern waterproofing, polyurethane grouts generally deliver superior strength, adhesion, and durability, making them the preferred choice for bridges, tunnels, dams, and other structural applications.

Acrylate gels remain valuable for soil stabilization and large-area waterproofing. However, when performance, reliability, and longevity are key, YURU Waterproof’s polyurethane grouting systems stand out as the optimal solution.

YURU Waterproof — Engineering Waterproofing Solutions That Last a Lifetime.

YURU Product solutions

Waterproof Coating

- One-component oil-based polyurethane waterproof coating

- One-component water-based polyurethane waterproof coating

- Two-component polyurethane waterproof coating

- Two-component 6.0Mpa polyurethane waterproof coating

- Transparent Waterproof Glue

- Nano Invisible Waterproof Agent

- Silicone Waterproof Coating

- Acrylic Waterproof Coating For Metal Roof

- JS Polymer Waterproof Coating

- High Elastic Liquid Rubber Waterproof Coating

- Cement-based Penetrating Crystallization Waterproof Coating