Contractor Trusted Microcrystalline Polyurea Grouting Material Supplier

Introduction: Why Contractors Need Trusted Suppliers?

In large-scale construction and engineering projects, contractors face enormous responsibility. They must deliver projects that are safe, durable, and cost-efficient, while also staying on schedule. Waterproofing is one of the most critical challenges contractors encounter. Even minor leaks can escalate into costly damages, project delays, and safety concerns.

That’s why choosing the right grouting material—and the right supplier—is essential. Among the many options available, microcrystalline polyurea grouting material has become the go-to solution for contractors seeking high-performance waterproofing.

At YURU Waterproof, we are proud to be recognized as a contractor trusted supplier of microcrystalline polyurea grouting material. With a focus on quality assurance, reliable supply chains, and engineering expertise, we support contractors worldwide in achieving waterproofing success.

What is Microcrystalline Polyurea Grouting Material?

Microcrystalline polyurea grouting material is a specialized injection compound designed for waterproofing, crack sealing, and structural reinforcement. It combines the toughness of polyurea with the density of a microcrystalline structure, creating a solution that is both strong and adaptable.

Core Features:

- High Density Sealing – Prevents water migration even under extreme hydrostatic pressure.

- Elastic Flexibility – Moves with structural shifts, reducing cracking.

- Fast Curing – Speeds up project completion.

- Durable Performance – Withstands harsh underground and industrial environments.

- Versatile Application – Effective in tunnels, basements, bridges, and more.

Compared with polyurethane or acrylate grouts, microcrystalline polyurea provides superior durability and lower shrinkage, making it ideal for long-term infrastructure reliability.

Why Do Contractors Trust Microcrystalline Polyurea Grouting Material?

Contractors across industries choose this material because it offers:

- Shorter Construction Periods – Thanks to fast curing and simplified application.

- Long-Term Waterproofing – Provides decades of protection without frequent reapplication.

- Adaptability – Works in both dry and wet conditions, including high-pressure zones.

- Lower Maintenance Costs – Prevents recurring leak issues, reducing project risks.

- Enhanced Safety – Reliable waterproofing reduces structural hazards.

By reducing both project uncertainty and lifecycle costs, microcrystalline polyurea grouting material has become one of the most contractor-trusted waterproofing solutions available today.

Key Performance Advantages of Microcrystalline Polyurea Grouting Material

When contractors evaluate waterproofing solutions, performance comes first. Microcrystalline polyurea grouting material excels in every critical area.

1. Strong Adhesion Across Materials

The material bonds securely to concrete, rock, masonry, and steel. This ensures there are no micro-gaps where water can seep through, creating airtight, watertight joints even in challenging conditions.

2. Superior Waterproofing Under Pressure

Thanks to its microcrystalline structure, the grout forms a non-porous, high-density seal capable of withstanding extreme hydrostatic pressure. It’s particularly effective for deep tunnels, underground garages, and dams where water pressure is constant.

3. Long-Term Structural Durability

Unlike conventional polyurethane grouts that shrink or degrade, microcrystalline polyurea remains stable and elastic for decades. It withstands seismic vibrations, freeze-thaw cycles, and soil settlement, ensuring long-term reliability.

4. Fast Curing, Efficient Projects

Construction delays are costly. This material cures in minutes, not hours, allowing contractors to resume operations quickly. For emergency leak repairs, the speed of application is invaluable.

5. High Resistance to Chemicals and Corrosion

In industrial zones or polluted groundwater environments, chemical resistance is vital. Microcrystalline polyurea resists acidic, alkaline, and saline exposure, making it the preferred choice for chemical plants, wastewater facilities, and coastal structures.

6. Flexibility and Customization

Contractors often face varied site conditions, from fine cracks to large voids. Microcrystalline polyurea can be formulated with different viscosities, ensuring suitability for precise injection applications as well as large-scale void filling.

7. Sustainability and Safety

All YURU Waterproof products, including microcrystalline polyurea grouting material, are low-VOC, environmentally friendly, and compliant with green building standards. This makes them suitable for modern sustainable construction practices.

These advantages explain why contractors worldwide rely on YURU Waterproof as their trusted supplier of microcrystalline polyurea grouting material.

Typical Applications and Engineering Case Studies

Microcrystalline polyurea grouting material has been widely used across industries. Below are common applications, along with real-world examples where YURU Waterproof has delivered results:

1. Subway and Tunnel Engineering

Application: Sealing leaks, filling voids, and reinforcing underground tunnel linings.

Case Study: In a metropolitan subway system, YURU Waterproof supplied tons of microcrystalline polyurea grout to prevent groundwater infiltration. The solution provided leak-free tunnels for decades, despite constant high-pressure groundwater exposure.

2. Bridges and Municipal Infrastructure

Application: Protecting bridge expansion joints, sealing cracks, and repairing drainage systems.

Case Study: In a large municipal bridge project, YURU Waterproof’s grout was used to extend service life by 20+ years, resisting freeze-thaw cycles and salt corrosion from de-icing chemicals.

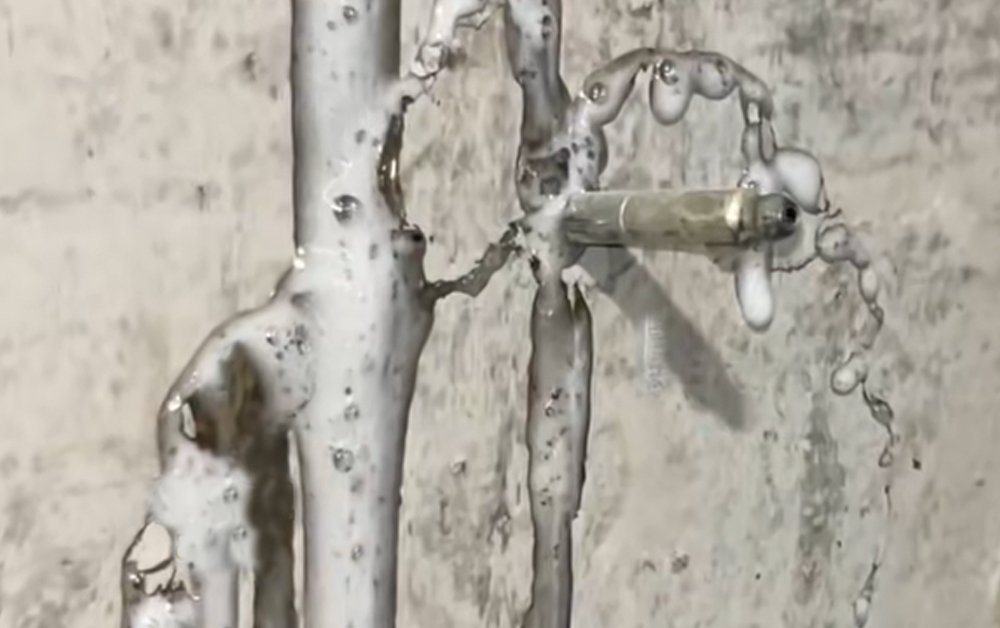

3. Commercial and Residential Basements

Application: Preventing seepage in basements, underground parking lots, and shopping malls.

Case Study: A commercial mall faced severe water ingress in its underground parking. YURU’s polyurea solution solved the problem permanently, saving millions in potential repair and tenant claims.

4. Industrial Facilities

Application: Waterproofing factory floors, tanks, and areas exposed to aggressive chemicals.

Case Study: YURU Waterproof worked with a chemical production facility, supplying customized grout that provided strong resistance to acids and alkalis while ensuring structural safety.

5. Water Management Projects

Application: Sealing reservoirs, dams, and wastewater treatment plants.

Case Study: For a government dam reinforcement project, YURU Waterproof delivered bulk materials that ensured zero leakage and long-term water containment, meeting public safety and environmental compliance standards.

6. Emergency Leak Repairs

Application: Quick response in tunnels, basements, or utility lines where leaks appear suddenly.

Case Study: In a high-speed rail tunnel, YURU’s fast-curing microcrystalline polyurea grout was applied to seal a leak within hours, preventing costly service interruptions.

These examples demonstrate why contractors across industries trust YURU Waterproof—because our products are tested and proven in real-world projects of critical importance.

Contractors’ Key Concerns and YURU’s Solutions

Concern: How long will the waterproofing last?

YURU provides materials tested to perform for decades.

Concern: Will it work in harsh environments?

Resistant to pressure, chemicals, and vibration, making it suitable for complex projects.

Concern: Will it delay construction timelines?

With fast curing, our materials help contractors stay on schedule.

Concern: Is it environmentally compliant?

YURU products are eco-friendly, VOC-compliant, and meet international standards.

Concern: Is supply stable and reliable?

With a global logistics network, YURU ensures stable bulk supply to contractors worldwide.

How to Select a Reliable Supplier?

When contractors choose a supplier for waterproofing materials, they should consider:

- Quality Certification – Verified and tested product batches.

- Production Capacity – Ability to meet urgent, large-scale orders.

- Technical Support – On-site guidance and application training.

- Proven Experience – References from successful large projects.

- Reliable Logistics – Timely delivery to keep projects on track.

YURU Waterproof meets all these requirements and is recognized globally as a contractor-trusted partner.

Why Contractors Trust YURU Waterproof?

At YURU Waterproof, we provide more than just materials—we deliver confidence, reliability, and expertise.

- Internationally certified quality

- Flexible wholesale and bulk purchase models

- Global logistics network for fast delivery

- Technical consultation and training

- Successful government and commercial project references

This is why contractors worldwide trust YURU Waterproof as their microcrystalline polyurea grouting material supplier of choice.

Conclusion: Partner with YURU Waterproof for Trusted Waterproofing

Contractors need a supplier they can trust—one who provides quality, reliability, and proven solutions.

By choosing YURU Waterproof, contractors gain access to microcrystalline polyurea grouting materials that deliver unmatched performance across projects of all sizes.

With decades of durability, chemical resistance, and strong adhesion, our solutions help contractors ensure that every project is leak-free, safe, and built to last.

Choose YURU Waterproof—your contractor trusted partner for microcrystalline polyurea grouting material supply.

YURU Product solutions

Waterproof Coating

- One-component oil-based polyurethane waterproof coating

- One-component water-based polyurethane waterproof coating

- Two-component polyurethane waterproof coating

- Two-component 6.0Mpa polyurethane waterproof coating

- Transparent Waterproof Glue

- Nano Invisible Waterproof Agent

- Silicone Waterproof Coating

- Acrylic Waterproof Coating For Metal Roof

- JS Polymer Waterproof Coating

- High Elastic Liquid Rubber Waterproof Coating

- Cement-based Penetrating Crystallization Waterproof Coating