How Epoxy Resin Injection Grouting Strengthens Structures?

Introduction — The Role of Epoxy Resin Injection in Structural Repair

Concrete is the backbone of modern infrastructure, yet over time it becomes vulnerable to cracking due to environmental stress, chemical exposure, and structural fatigue.

For critical infrastructure such as bridges, tunnels, and industrial facilities, these cracks are more than cosmetic — they threaten the stability and service life of entire structures.

Epoxy resin injection grouting has emerged as one of the most effective and durable techniques for restoring the integrity of damaged concrete.

By injecting low-viscosity epoxy resins into fine cracks, engineers can bond the fractured sections together, creating a seamless, high-strength repair that not only seals leaks but also restores the load-bearing capacity of the structure.

Unlike polyurethane grouting, which focuses on waterproofing and flexibility, epoxy resin injection is a structural repair method designed to rebuild and reinforce. It has become the go-to solution in bridges, tunnels, basements, and high-load bearing facilities where safety and strength are non-negotiable.

Understanding the Mechanism of Epoxy Resin Injection Grouting

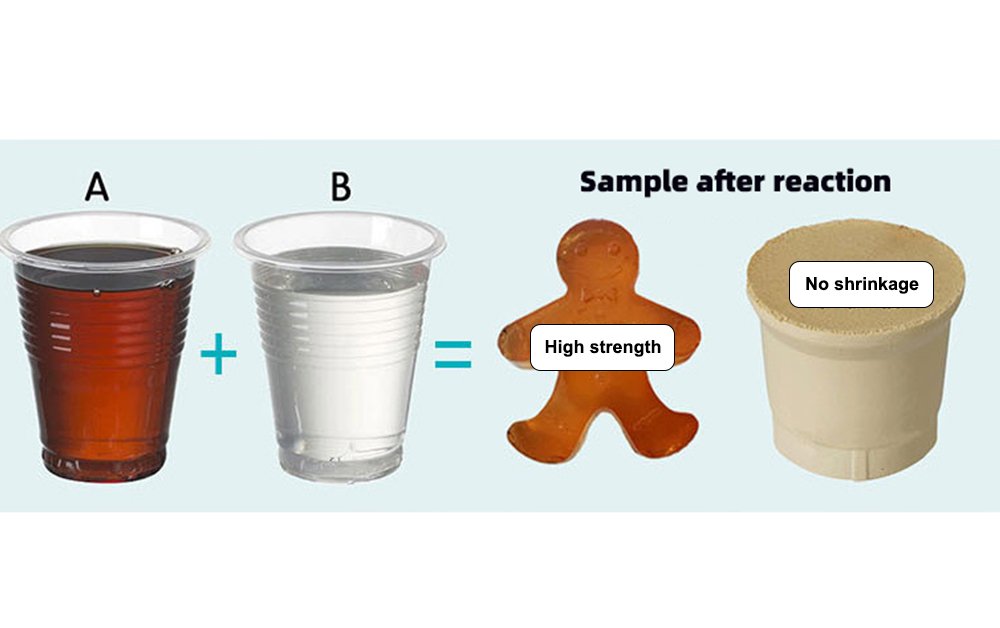

Epoxy resin injection grouting is based on a chemical reaction between epoxy resin and hardener, which forms a dense, rigid three-dimensional molecular structure upon curing.

This cured resin exhibits exceptional compressive, tensile, and adhesive strength, allowing it to bond fractured concrete surfaces together as a single monolithic element.

Key working principles include:

- The resin’s low viscosity allows it to penetrate fine cracks (as narrow as 0.1 mm).

- Once injected, the resin reacts and hardens, creating a waterproof and structural seal.

- The adhesive bond formed between epoxy and concrete often exceeds the internal strength of the concrete itself.

Through this mechanism, epoxy resin injection effectively transforms a cracked structure into a unified solid mass, eliminating voids, stopping water ingress, and preventing future deterioration.

To ensure performance consistency, professional formulations typically comply with standards.

Key Benefits of Using Epoxy Resin Injection Grouting in Construction

Epoxy resin injection grouting provides numerous advantages for structural engineers, contractors, and maintenance teams. Its benefits extend beyond crack sealing, offering structural restoration, enhanced strength, and longevity.

1. High Strength and Excellent Adhesion

Epoxy resins bond strongly to concrete, steel, and masonry, achieving compressive strengths up to or even exceeding that of the host concrete. This ensures permanent structural recovery.

2. Deep Crack Penetration

Thanks to their low viscosity, YURU’s epoxy injection systems can infiltrate hairline cracks, ensuring thorough filling and bonding without leaving voids.

3. Chemical and Environmental Resistance

Epoxy grouts resist corrosion, chemical attack, and moisture infiltration — making them ideal for industrial plants, wastewater facilities, and marine structures.

4. Long-Term Durability

Unlike flexible sealants that degrade over time, epoxy resin injection forms a rigid, stable matrix that remains intact under temperature cycles, vibrations, and heavy loads.

5. Enhanced Structural Integrity

The cured epoxy restores the load-transfer capacity of concrete components, ensuring the structure behaves as a single unit — crucial in load-bearing columns, beams, and slabs.

6. Minimal Downtime and Fast Curing

Modern epoxy systems allow rapid curing even under damp conditions, reducing project downtime and labor costs.

By combining these properties, epoxy resin injection grouting offers a reliable, long-term approach to structural restoration and preventive maintenance.

Applications of Epoxy Resin Injection Grouting in Structural Engineering

Epoxy resin injection grouting is used in a wide variety of civil and industrial projects, particularly where structural strength, durability, and precision are required.

1. Bridges and Elevated Structures

- Used for crack sealing in bridge decks, beams, and girders to prevent moisture ingress and restore full structural capacity.

2. Tunnels and Underground Facilities

- Applied to repair concrete linings in metro tunnels, shafts, and underground parking structures where hydrostatic pressure and vibration are common.

3. Industrial and Power Plants

- Epoxy injection strengthens foundations, floors, and machinery bases subjected to high loads and chemical exposure.

4. Dams, Reservoirs, and Water Infrastructure

- Essential for sealing structural cracks that risk water leakage and erosion over time.

5. Earthquake-Damaged Buildings and Seismic Retrofitting

- Used to restore shear walls, beams, and columns, helping to recover or even improve post-damage load capacity.

6. Concrete Floors and Slabs

- An effective solution for industrial floor repairs, ensuring smooth and strong reinforcement without replacing the entire slab.

In each application, epoxy resin injection not only repairs cracks but also extends service life, ensuring that structures continue to perform safely under long-term loading.

Comparison — Epoxy Resin Injection vs Polyurethane Injection Grouting

While both epoxy and polyurethane injections are popular, they serve different engineering purposes. Understanding their differences helps contractors choose the right system for their projects.

| Feature | Epoxy Resin Injection | Polyurethane Injection |

|---|---|---|

| Purpose | Structural crack repair | Waterproofing & non-structural sealing |

| Curing Type | Rigid, high-strength solid | Flexible, elastic foam |

| Crack Width | 0.1 – 2 mm | 0.2 – 10 mm |

| Load Bearing | Yes | No |

| Chemical Resistance | Excellent | Moderate |

| Application Area | Concrete repair and reinforcement | Leak sealing and waterproofing |

| Lifespan | Long-term | Medium-term |

Epoxy resin injection is the preferred choice for structural strengthening, while polyurethane systems are more suitable for water leak sealing and flexible crack treatment.

Best Practices for Applying Epoxy Resin Injection Grouting

To ensure effective and long-lasting results, epoxy resin injection must follow strict application protocols.

Below are industry-recognized best practices:

- Crack Inspection and Evaluation

Use ultrasonic or visual inspection to determine the depth, direction, and cause of cracking.

- Surface Preparation and Port Installation

Clean the crack, seal its surface, and install injection ports at regular intervals to ensure even distribution.

- Vacuum and Pressure Control

Apply low-pressure injection to prevent air pockets or voids; use vacuum techniques for fine cracks.

- Controlled Mixing and Injection

Mix resin and hardener precisely according to the manufacturer’s ratio to ensure full polymerization.

- Curing and Quality Testing

Allow sufficient curing time under stable temperature and humidity, then perform adhesion and hardness tests.

- Safety and Environmental Considerations

Use low-VOC, solvent-free epoxy systems to minimize site emissions and worker exposure.

- Compliance with International Standards

Follow international standards for consistent quality assurance.

By following these practices, engineers can achieve reliable, consistent repairs that meet modern safety and sustainability requirements.

YURU Waterproof — Professional Supplier of Epoxy Grouting Solutions

YURU Waterproof is a leading manufacturer and supplier of high-performance waterproofing and injection grouting materials for industrial and construction projects worldwide.

Our epoxy resin injection products are formulated to provide high bonding strength, low shrinkage, and superior crack penetration, ensuring durable and structural-grade repairs.

YURU’s full range of grouting materials includes:

- Water-based Hydrophilic Polyurethane Grouting Materials

- Oil-based Hydrophobic Polyurethane Grouting Materials

- Acrylate Grouting Materials

- Epoxy Resin Injection Grouting Materials

- Polyurea and Microcrystalline Polyurea Grouting Materials

YURU Waterproof is committed to developing eco-friendly, high-performance waterproofing systems that meet RoHS, and ISO environmental standards.

Our materials are trusted by contractors, infrastructure developers, and engineering consultants in projects requiring durability and compliance with global safety codes.

FAQ Section

- What is epoxy resin injection grouting used for?

It is primarily used for repairing and bonding structural cracks in concrete elements, restoring their load-bearing and waterproofing capacity.

- Can epoxy resin injection stop water leaks?

Yes, though its main function is structural bonding, it can also provide an effective waterproof seal when properly injected into cracks.

- What is the difference between hydrophilic and epoxy grouting materials?

Hydrophilic polyurethane reacts with water to form flexible foam for leak sealing, while epoxy resin cures into a rigid solid for structural restoration.

- Is epoxy resin injection suitable for wet cracks?

Yes, modern formulations, including those from YURU Waterproof, are moisture-tolerant and perform well on damp surfaces.

- How long does an epoxy-injected repair last?

When applied correctly, epoxy resin injection repairs can last for decades, often outlasting the original concrete.

Conclusion

Epoxy resin injection grouting is a proven solution for restoring concrete strength and structural integrity. Its deep penetration and high bond strength make it ideal for long-term repairs in critical infrastructure.

For reliable, high-performance grouting materials, YURU Waterproof provides a full range of epoxy and polyurethane injection systems designed for durability, precision, and sustainability.

YURU Waterproof — Trusted Solutions for Stronger, Longer-Lasting Structures.

YURU Product solutions

Waterproof Coating

- One-component oil-based polyurethane waterproof coating

- One-component water-based polyurethane waterproof coating

- Two-component polyurethane waterproof coating

- Two-component 6.0Mpa polyurethane waterproof coating

- Transparent Waterproof Glue

- Nano Invisible Waterproof Agent

- Silicone Waterproof Coating

- Acrylic Waterproof Coating For Metal Roof

- JS Polymer Waterproof Coating

- High Elastic Liquid Rubber Waterproof Coating

- Cement-based Penetrating Crystallization Waterproof Coating