How Long Can a PU Injection Last?

Introduction

PU (polyurethane) injection is a widely trusted method for repairing leaks and strengthening structures. It’s fast-acting, highly effective, and often applied in environments where other waterproofing solutions fall short. But a key question many people ask is: How long can a PU injection last?

In this article, we’ll explore the expected lifespan of PU injection systems, what factors affect durability, how to spot when repairs are needed, and how YURU Waterproof helps clients ensure long-term performance and cost-efficiency.

What Is PU Injection and How Does It Work?

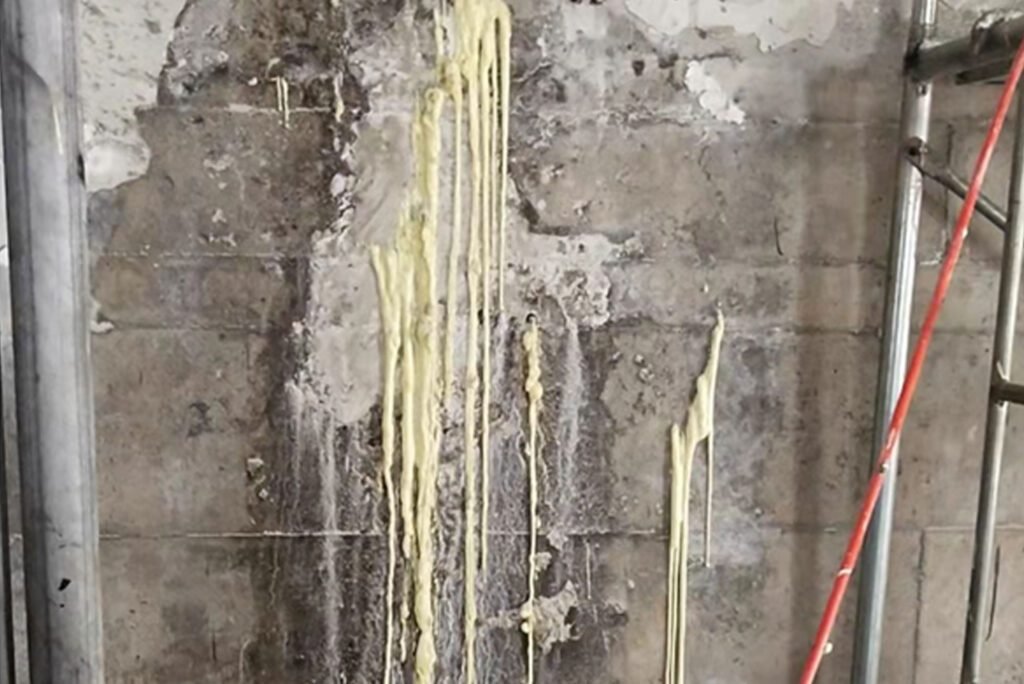

PU injection, or polyurethane injection, involves injecting a reactive resin into cracks, joints, or voids within concrete and masonry structures. When it comes into contact with water or moisture, the resin expands into a dense foam that fills the void and creates a watertight seal.

PU injection is commonly used in:

- Leaking basements

- Concrete walls and foundations

- Underground tunnels and utility shafts

- Water tanks and retaining structures

Its fast curing time, flexibility, and ability to adapt to irregular surfaces make it a leading method for structural and waterproofing repairs.

How Long Does PU Injection Typically Last?

Under proper conditions, a PU injection system can last 5 to 20 years—or even longer. Its longevity depends heavily on environmental stress, application quality, and material grade.

In stable environments with little structural movement and minimal moisture pressure, PU injections can last well beyond a decade. However, in areas subject to frequent vibration, shifting, or continuous water flow, periodic inspection and maintenance may be needed sooner.

Proper product selection and expert application are essential to maximize lifespan and avoid premature failure.

What Factors Affect the Durability of PU Injection?

The following factors play a major role in how long PU injection will last:

| Factor | Impact on Durability |

| Material quality | Determines foam strength, flexibility, and resistance |

| Type and size of crack | Large or moving cracks may shorten lifespan |

| Application depth & method | Correct injection pressure ensures full penetration |

| Surrounding environment | Humid, acidic, or wet conditions may accelerate degradation |

| Surface preparation | Poorly cleaned or prepped surfaces can weaken adhesion |

| Post-installation movement | Settlement or vibrations may reopen sealed cracks |

Understanding these factors helps you make informed choices and increase system reliability.

How Can You Tell If PU Injection Needs Repair or Replacement?

Here are key signs that a PU injection system may be losing effectiveness:

- Water is reappearing at or around the original leak area.

- New cracks have developed nearby.

- Foam degradation (shrinking, discoloration, or softening) is visible

- Humidity or dampness is detected near injection sites.

- Vibrations or settling have shifted the structure.

Periodic inspection is recommended, especially in high-risk or high-traffic areas. Early detection of failure can prevent expensive water damage and allow for targeted re-injection.

How Does YURU Waterproof Ensure Long-Lasting PU Injection Systems?

At YURU Waterproof, we don’t just supply PU materials—we provide a complete performance solution. Here’s how we help ensure long-term results:

- Custom PU formulas tailored to the substrate and moisture conditions

- Guidance for injection techniques and foam control

- Durability-tested resins for water, chemical, and structural resistance

- Global logistics and technical support for project-wide implementation

- Real-world performance in tunnels, basements, dams, and infrastructure repairs

Our goal is simple: deliver waterproofing systems that last—and support clients at every stage of the project.

Conclusion

So, how long can a PU injection last? With the right materials, proper technique, and ongoing attention, PU injections can deliver reliable, long-term waterproofing and structural support. Understanding the influencing factors and staying proactive with inspections will ensure you get the most out of your investment.

Looking to maximize durability in your next project?

YURU Waterproof is ready to assist you with premium products and expert service.

Contact us today to get personalized recommendations for your PU injection needs.

YURU Product solutions

Waterproof Coating

- One-component oil-based polyurethane waterproof coating

- One-component water-based polyurethane waterproof coating

- Two-component polyurethane waterproof coating

- Two-component 6.0Mpa polyurethane waterproof coating

- Transparent Waterproof Glue

- Nano Invisible Waterproof Agent

- Silicone Waterproof Coating

- Acrylic Waterproof Coating For Metal Roof

- JS Polymer Waterproof Coating

- High Elastic Liquid Rubber Waterproof Coating

- Cement-based Penetrating Crystallization Waterproof Coating