How to Choose the Right Grouting Material for Tunnel and Basement Waterproofing?

Waterproofing in deep underground structures such as tunnels, subways, and basements demands precision, durability, and technical understanding. The choice of grouting material directly determines how effectively water ingress is controlled and how long the structure can stay protected.

For project managers, contractors, and distributors, selecting the right product is not just about cost—it’s about compatibility, performance, and reliability.

This guide explores the key factors, types of materials, and supplier criteria to help you make informed decisions. All insights are based on YURU Waterproof’s experience as a professional manufacturer and supplier serving global infrastructure projects.

Understanding the Role of Grouting Materials in Tunnel and Basement Waterproofing

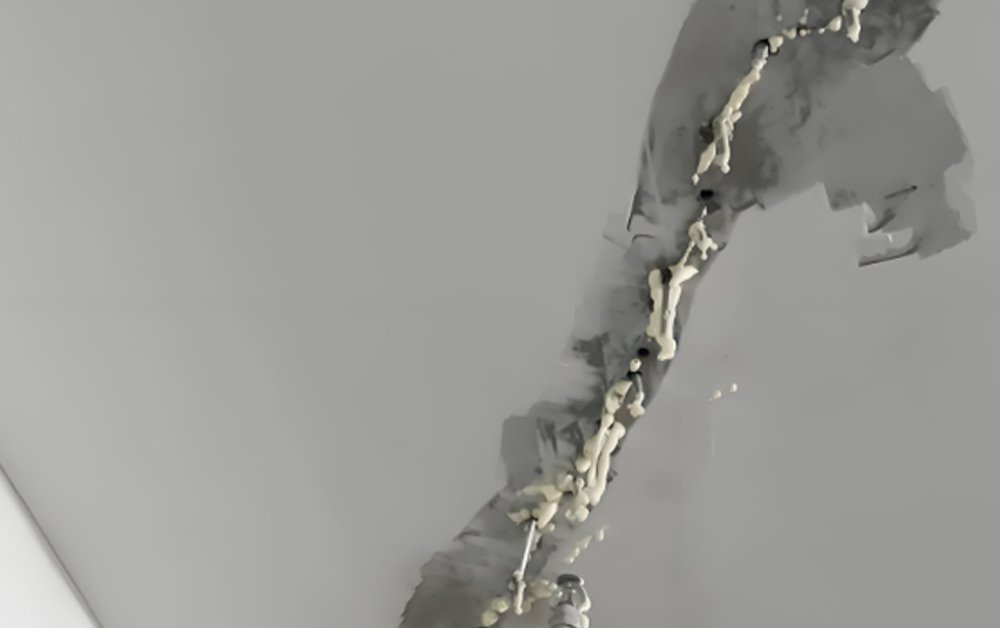

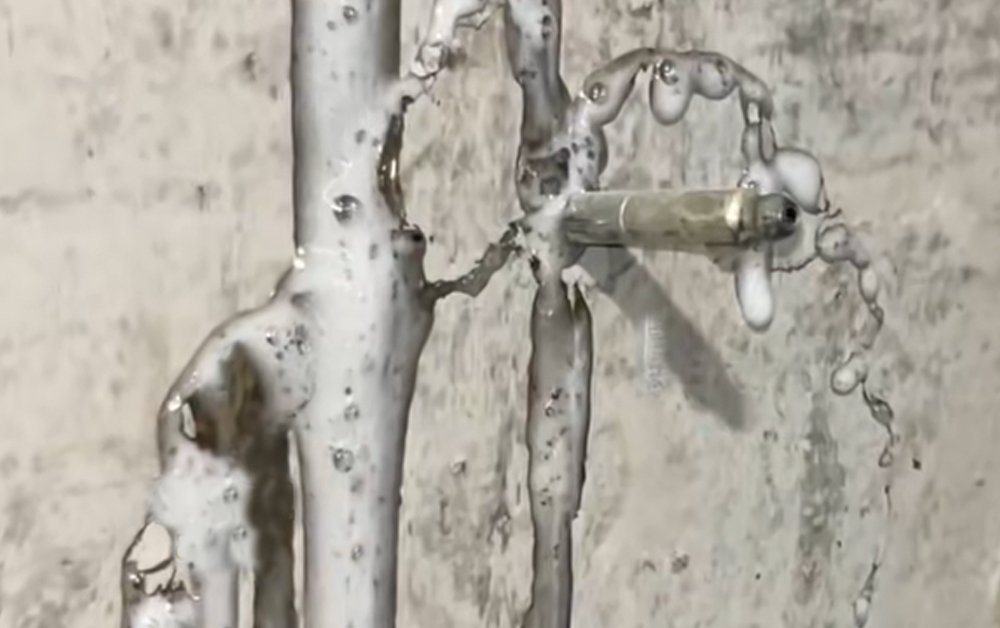

In underground construction, concrete inevitably develops cracks, cold joints, and honeycombs due to pressure, settlement, or thermal expansion. These defects create pathways for water ingress, endangering the structure’s integrity and long-term durability.

Grouting materials act as a secondary waterproofing defense by filling voids and sealing leak paths. When injected under pressure, they:

- Block and seal active leaks and micro-cracks

- Reinforce weak concrete zones

- Restore structural bonding

- Prevent future corrosion or concrete spalling

Injection grouting is a non-destructive waterproofing method that restores watertightness without extensive excavation or demolition. The result is a strengthened, waterproof barrier capable of resisting hydrostatic pressure for decades.

Key Challenges in Tunnel and Basement Waterproofing Projects

Underground waterproofing projects face some of the most difficult environmental and structural conditions:

- High hydrostatic pressure from groundwater tables or seepage.

- Dynamic crack movement caused by vibrations or structural settlement.

- Temperature fluctuations affecting material elasticity.

- Difficult access zones that limit conventional membrane application.

- Long-term exposure to chemicals, salts, or aggressive groundwater.

For these reasons, an effective waterproofing design must consider the material’s reactivity, elasticity, adhesion, and compatibility with existing structures. The wrong grout selection can lead to leakage recurrence, waste of material, and costly repair cycles.

Main Types of Grouting Materials for Waterproofing Projects

Selecting the right type of grouting material is crucial for long-term success. Each formulation is engineered to handle specific issues—such as dynamic cracks, high-pressure leaks, or soil stabilization.

Below are the most widely used materials in professional waterproofing projects and their technical profiles.

Polyurethane (PU) Grouting Material

Polyurethane grout remains the industry’s go-to option for leak sealing and emergency repairs. When it reacts with water, it expands into an elastic foam that seals joints and voids effectively.

- Advantages: Quick reaction, strong adhesion, adjustable expansion ratio, and long-term flexibility.

- Applications: Ideal for active crack sealing in tunnels, retaining walls, and underground basements.

- Key Benefit: Rapid reaction makes it ideal for high-pressure, continuous water ingress.

Acrylate Grouting Material

Acrylate systems are known for their ultra-low viscosity, allowing deep penetration into fine cracks. Once cured, they form a soft gel resistant to water and chemicals.

- Advantages: Excellent permeability, adjustable gel time, minimal shrinkage.

- Applications: Micro-crack sealing and soil consolidation around tunnel linings.

- Key Benefit: Creates a continuous waterproof membrane that remains flexible even after years.

Epoxy Resin Grouting Material

Epoxy resin grouts are used when structural strengthening is required in addition to waterproofing.

- Advantages: High bonding strength, superior mechanical performance, and chemical resistance.

- Applications: Structural crack injection and reinforcement of load-bearing concrete.

- Key Benefit: Combines durability and mechanical repair, ideal for high-stress sections of tunnels.

Polyurea Grouting Material

Polyurea technology bridges the gap between polyurethane’s flexibility and epoxy’s toughness.

- Advantages: Fast curing, high elongation, excellent adhesion to damp concrete.

- Applications: Used in tunnels, metros, and basements where structures experience vibration or deformation.

- Key Benefit: Maintains watertightness even under continuous movement.

Microcrystalline Polyurea Grouting Material

A next-generation product that uses microcrystalline molecular chains to improve elasticity and crack-bridging capacity.

- Advantages: Superior flexibility, long-term aging resistance, and chemical stability.

- Applications: Designed for expansion joints, deformation seams, and moving cracks.

- Key Benefit: Ensures permanent waterproofing performance even with frequent joint movement.

Cementitious Grout or Microfine Cement

Cementitious grouts are the traditional yet reliable solution for large-scale injection and soil stabilization.

- Advantages: Low cost, strong compressive strength, compatibility with concrete, and proven durability.

- Applications: Pre-grouting in tunnel linings and foundation stabilization.

- Key Benefit: Ideal for preventive waterproofing in large infrastructure projects.

Each type serves a unique purpose:

- PU and Acrylate → Best for active leak sealing

- Epoxy Resin → For structural reinforcement

- Polyurea & Microcrystalline Polyurea → For dynamic or moving joints

- Cementitious Systems → For large-scale filling and stabilization

Choosing the right system requires evaluating leak type, structure behavior, and project conditions.

Technical Criteria for Selecting the Right Grouting Material

When comparing products, professionals should evaluate these critical performance indicators:

| Parameter | Description | Importance |

|---|---|---|

| Viscosity & Penetration | Ability to enter fine cracks | Ensures complete sealing |

| Reaction Time & Gel Speed | Determines how fast leaks can be stopped | Vital for emergency projects |

| Expansion Ratio | Affects foam density and pressure resistance | Prevents void re-leakage |

| Bonding Strength | Adhesion between grout and concrete | Guarantees durability |

| Elasticity & Flexibility | Ability to accommodate movement | Prevents cracking under stress |

| Chemical Resistance | Withstands salts, acids, and groundwater chemicals | Ensures longevity |

| Environmental Safety (VOC) | Compliance with green building standards | Reduces health risks |

A reliable supplier will provide TDS, MSDS, and third-party test reports (SGS, CE, ISO) for quality verification.

Application Techniques and Common Mistakes in Grouting Works

Even the best materials can fail if applied incorrectly. Common challenges include incomplete filling, excessive pressure, and improper mixing.

Best-practice recommendations:

- Clean cracks and remove contaminants before injection.

- Control injection pressure according to substrate porosity.

- Mix material precisely as per ratio; avoid premature reactions.

- Monitor flow rate to prevent over-expansion or blow-outs.

- Conduct pressure retention tests to verify sealing integrity.

- Perform secondary grouting if needed for complete sealing.

At YURU Waterproof, our technical service team provides on-site guidance and customized injection plans for complex conditions like high-pressure leakage or limited-space tunnels.

How to Evaluate Grouting Material Suppliers and Manufacturers?

Choosing the right partner ensures consistent product quality and project reliability. Evaluate suppliers based on:

- Certification & Quality Control: ISO9001/ISO14001, SGS, CE.

- Experience: Proven record in metro, tunnel, and basement waterproofing.

- R&D Capability: Ability to customize formulations (OEM/ODM).

- Technical Support: Engineering consultation and application training.

- Supply Stability: Capacity to deliver bulk orders consistently.

- Global Service: Export capability and compliance with international standards.

YURU Waterproof has supplied professional grouting and waterproofing materials for infrastructure projects across Asia, Europe, and the Middle East. We provide polyurethane, acrylate, and microcrystalline polyurea systems tailored to each project’s structural and environmental requirements.

Why YURU Waterproof is Your Reliable Partner for Tunnel and Basement Projects?

YURU Waterproof is not only a material supplier but a solution partner.

We offer:

- Complete product lines: waterproof coatings, injection grouting systems, and flooring materials.

- OEM customization with private labeling.

- Strict QA/QC processes and sustainability compliance.

- In-house R&D to adapt materials to local conditions.

- Global logistics and technical documentation support.

With over 20 years of industrial expertise, YURU has helped contractors achieve leak-free tunnel and basement structures through consistent performance and long-term cooperation.

Contact YURU Waterproof today to request a tailored grouting material solution for your next underground waterproofing project.

FAQs

1. What is the best grouting material for tunnel waterproofing?

For active water leaks, polyurethane grouting material is recommended due to its fast reaction and expansion. For long-term stability, microcrystalline polyurea offers excellent flexibility.

2. Can epoxy grouting be used for waterproofing only?

Epoxy is mainly for structural repair. While it seals cracks, it’s less flexible, so it’s used where reinforcement is required.

3. How do I choose between PU and Acrylate grout?

PU suits dynamic or high-pressure leaks; Acrylate works better for micro-cracks and soil stabilization.

4. Is microcrystalline polyurea a new technology?

Yes. It’s an advanced polyurea system with crystalline structures that improve elasticity and chemical resistance, ideal for moving joints.

5. Can YURU Waterproof customize grout formulas for specific projects?

Absolutely. YURU Waterproof provides OEM and customized formulation services to meet project-specific requirements.

6. How long does a grouting waterproofing system last?

With proper selection and application, high-quality grouting systems can last 20 years or more without significant degradation.

7. Does YURU Waterproof export internationally?

Yes, YURU supplies products to more than 30 countries with full export documentation and technical support.

Conclusion

Selecting the right grouting material for tunnel and basement waterproofing requires balancing engineering demands, environmental conditions, and economic considerations. From polyurethane and acrylate to microcrystalline polyurea, every formulation has its purpose.

With YURU Waterproof, you gain more than a product—you gain a technical partner committed to long-term reliability, innovation, and service excellence.

Visit YURU Waterproof to explore our full range of injection grouting materials and waterproofing solutions.

YURU Product solutions

Waterproof Coating

- One-component oil-based polyurethane waterproof coating

- One-component water-based polyurethane waterproof coating

- Two-component polyurethane waterproof coating

- Two-component 6.0Mpa polyurethane waterproof coating

- Transparent Waterproof Glue

- Nano Invisible Waterproof Agent

- Silicone Waterproof Coating

- Acrylic Waterproof Coating For Metal Roof

- JS Polymer Waterproof Coating

- High Elastic Liquid Rubber Waterproof Coating

- Cement-based Penetrating Crystallization Waterproof Coating