How to Identify the Right Type of Polyurethane Grout for Crack Injection?

Selecting the correct polyurethane grout for crack injection is a practical decision that affects project durability, cost, and long-term maintenance. This guide walks through the step-by-step logic used by contractors, engineers and procurement teams to identify the best material for a given crack repair or waterproofing scenario.

It focuses on real-world considerations — not just lab data — and shows how to match product type to application, site conditions, and execution constraints. Where appropriate, we point out how YURU Waterproof supports tailored OEM formulations and on-site technical assistance.

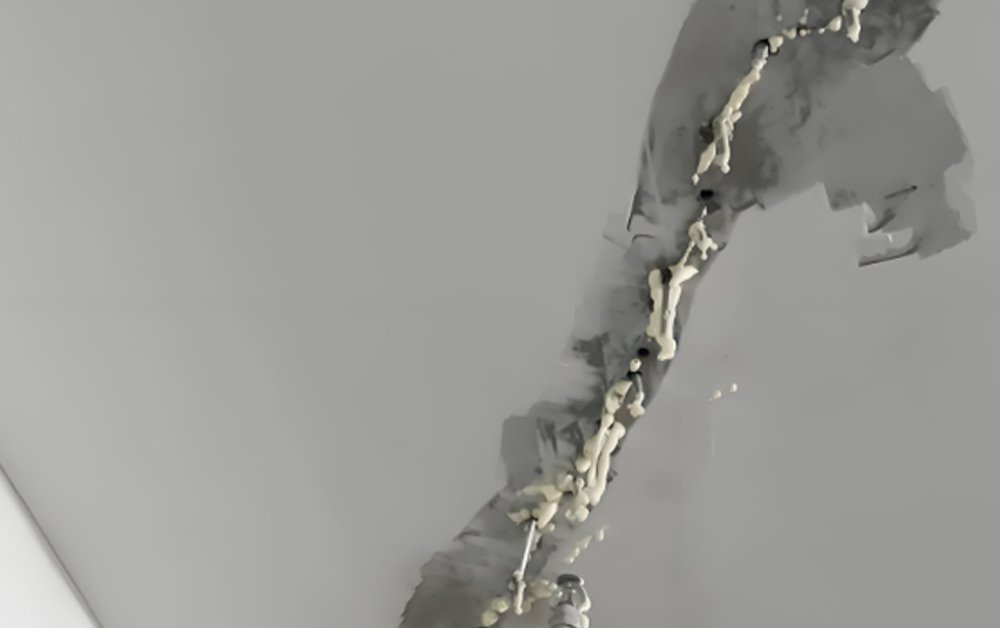

Start with the problem diagnosis — what kind of crack or leak are you fixing?

Before choosing any injection material, collect clear facts about the defect:

- Is the crack actively leaking (running water) or only weeping?

- Is the structural movement present — i.e., is the crack static, slowly moving, or cyclically opening and closing?

- What is the crack width and depth? Are there connected voids or honeycombing?

- Is the environment saturated, intermittently wet, or primarily dry?

- Do you need immediate stop-the-leak action, or is a long-term flexible seal more important?

These observations determine whether the repair needs a fast-reacting, high-strength seal or a flexible, long-lasting membrane. For example, high-flow leak points often demand a rapid, hydrophobic grout to stop water immediately; persistent dampness or micro-porosity may be better addressed with a hydrophilic product that swells and forms a continuous gasket.

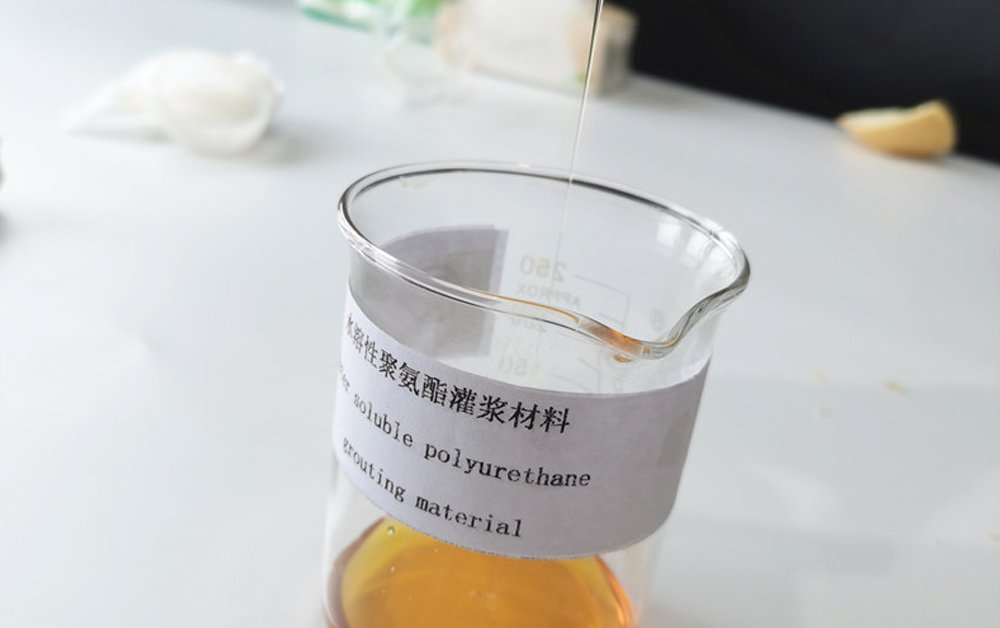

Know the basic polyurethane grout categories and what they do

Polyurethane injection resins are versatile, but they are not one-size-fits-all. The main categories contractors encounter are:

- Hydrophilic polyurethane grouts — designed to absorb moisture and expand. They form soft, flexible seals that can maintain contact with rough concrete and re-seal micro-movement. Use them where continuous dampness is present and elasticity is required.

- Hydrophobic polyurethane grouts — repel additional water and react quickly into a closed-cell foam or dense elastomeric plug. They excel at rapid leak stoppage and withstanding water pressure.

- Single-component (1K) polyurethane systems — moisture-curing products that are easy to handle and suitable for smaller repairs and maintenance work.

- Two-component (2K) polyurethane systems — require on-site mixing or high-pressure grouting equipment; they offer more controlled reaction profiles and are preferred for demanding applications and bulk injections.

Each category brings different handling, equipment and execution needs. Matching those to field realities is essential.

Match material behavior to crack type and water condition

Below are practical matchings that field teams use:

- Running, high-pressure leaks → Hydrophobic 2K polyurethane

These leaks require immediate stoppage. Hydrophobic 2K systems set quickly and can form a dense plug under pressure. - Persistent wetness, hairline cracks, seepage through porous concrete → Hydrophilic grouts

These grouts penetrate fine capillaries and swell to create a flexible water-resistant network that accommodates micro-movement. - Moving joints or dynamic cracks → Flexible hydrophilic systems

High elasticity and fatigue resistance are crucial where the substrate will repeatedly move. - Large voids, honeycombing, or cavities behind concrete → High-viscosity 2K systems or staged injection with cementitious pre-grouting

Often a combined approach (cementitious to fill bulk void, followed by polyurethane to seal) gives best results. - Repair where minimal disruption is allowed (tight access, low noise) → Single-component (1K) moisture-cure PU

Easier logistics, less equipment; good for patch repairs when reaction speed is moderate.

Consider practical site factors that influence material choice

Beyond chemistry, these practical constraints matter:

- Ambient temperature and humidity: Some PU systems require minimum temperatures or humidity to cure properly. High humidity can accelerate 1K curing; low temperature can slow it down.

- Safety and regulations: Low-VOC, low-odor formulas can be necessary in occupied spaces. Check local environmental and transport rules for reactive resins.

- Curing time vs. production schedule: Fast cure reduces downtime, but may limit penetration depth. Slower systems penetrate deeper but require more monitoring.

- Warranty and lifecycle expectations: For critical infrastructure, insist on suppliers that provide technical backups and documented test data.

YURU Waterproof advises on these trade-offs and can supply both material and technical guidance, ensuring product selection lines up with logistics and safety constraints.

Inspect supplier documentation and test evidence

A technical decision should be evidence-based. Ask suppliers for:

- Technical Data Sheets (TDS) that include recommended substrate types, application parameters, and typical performance.

- Safety Data Sheets (MSDS/SDS) for handling and transport requirements.

- Site case studies showing similar crack geometry and conditions.

- Third-party test reports where available (adhesion, aging, salt spray for aggressive environments).

- Sample kits and trial instructions — run small trials to validate penetration, reaction time and final performance on actual substrate.

Reliable manufacturers (such as YURU Waterproof) provide comprehensive TDS/MSDS, trial guidance and bespoke formulation options for OEM customers.

Plan the injection technique to match the grout

Injection technique is as important as material choice. Common approaches include:

- Low-pressure sequential injection — useful for permeable substrates and hydrophilic grouts; allows penetration into fine cracks gradually.

- High-pressure single-shot injection — used with hydrophobic 2K grouts to stop active leaks quickly.

- Packers & staged port injections — for long or deep cracks, inject through multiple ports to ensure even distribution.

- Back-injection and curtain grouting — for large voids and surrounding soil stabilization, combine cementitious and PU stages.

Monitor pressure, flow and reaction in real time. Adjust port spacing, grout viscosity and injection rate based on feedback. YURU Waterproof can provide injection protocols and training — tailored to the chosen grout type and on-site conditions.

Evaluate lifecycle, maintenance and monitoring needs

A repair is only as good as its long-term performance plan. Consider:

- Durability demands: Some projects require lasting protection for decades; choose systems and suppliers proven in similar exposure.

- Maintenance access: If inspection is difficult, favor solutions with proven longevity and less need for rework.

- Compatibility with coatings or overlays: If a roof or surface will be recoated, ensure the grout and overlay systems are compatible.

- Monitoring strategy: Hydrostatic tests, short-interval visual inspections, and leak monitoring help validate the repair.

YURU Waterproof supports lifecycle planning and can provide material performance data to feed into asset management systems.

Practical checklist for on-site decision makers

Use this condensed checklist before ordering and injecting:

- Confirm crack type: active leak / seepage / movement / void.

- Decide primary objective: immediate stop / long-term flexible seal / structural strengthening.

- Assess site logistics: access, mixers, pumps, temperature/humidity.

- Request TDS/MSDS and trial sample from supplier.

- Validate reaction time and penetration on site test.

- Choose injection equipment and porting plan.

- Implement injection with pressure and flow monitoring.

- Document batch numbers, injection volumes and cure observations.

Following these steps reduces risk and improves predictability.

Why choose YURU Waterproof for polyurethane grout and injection support?

YURU Waterproof is a specialist in waterproof materials and injection systems serving contractors, distributors and project owners. Our strengths include:

- Product breadth: 1K and 2K polyurethanes, hydrophilic and hydrophobic formulations, and other injection grouts.

- OEM customization: We adapt reaction profiles, viscosity and expansion characteristics to project requirements.

- Technical service: Guidance, injection plans, training and trial mixes.

- Quality assurance: Batch testing, TDS/MSDS, and export compliance for global projects.

- Project track record: Successful repairs across building basements, metro tunnels, parking structures and bridges.

If you need material samples, custom formulations or an on-site evaluation, contact YURU Waterproof for a tailored solution that matches both engineering needs and execution constraints.

Conclusion

Choosing the right polyurethane grout for crack injection is a mix of diagnosis, material science and execution discipline. If you’d like a site-specific recommendation, YURU Waterproof can provide: a short on-site assessment, trial sample packs matched to your substrate, and a full injection protocol.

Contact YURU Waterproof for sample requests and technical support.

YURU Product solutions

Waterproof Coating

- One-component oil-based polyurethane waterproof coating

- One-component water-based polyurethane waterproof coating

- Two-component polyurethane waterproof coating

- Two-component 6.0Mpa polyurethane waterproof coating

- Transparent Waterproof Glue

- Nano Invisible Waterproof Agent

- Silicone Waterproof Coating

- Acrylic Waterproof Coating For Metal Roof

- JS Polymer Waterproof Coating

- High Elastic Liquid Rubber Waterproof Coating

- Cement-based Penetrating Crystallization Waterproof Coating