Hydrophilic VS Hydrophobic Polyurethane Grout: What’s the Real Difference?

Understanding Polyurethane Grout

Polyurethane grout, also known as polyurethane injection resin, is one of the most reliable waterproofing and crack repair materials in the construction industry. It is widely used to seal water leakage in tunnels, basements, parking structures, subways, dams, and other concrete infrastructures.

This chemical grout reacts with water to form a durable, elastic, and watertight structure within cracks or joints. Depending on its chemistry and reaction to water, polyurethane grout can be classified into two main types: hydrophilic (water-loving) and hydrophobic (water-repelling).

Each type has unique advantages, and understanding their differences helps contractors and engineers choose the best material for their project conditions.

YURU Waterproof, as a professional manufacturer and OEM supplier in China, provides both hydrophilic and hydrophobic polyurethane grouts with customizable formulations designed for long-term waterproofing performance.

What Is Hydrophilic Polyurethane Grout?

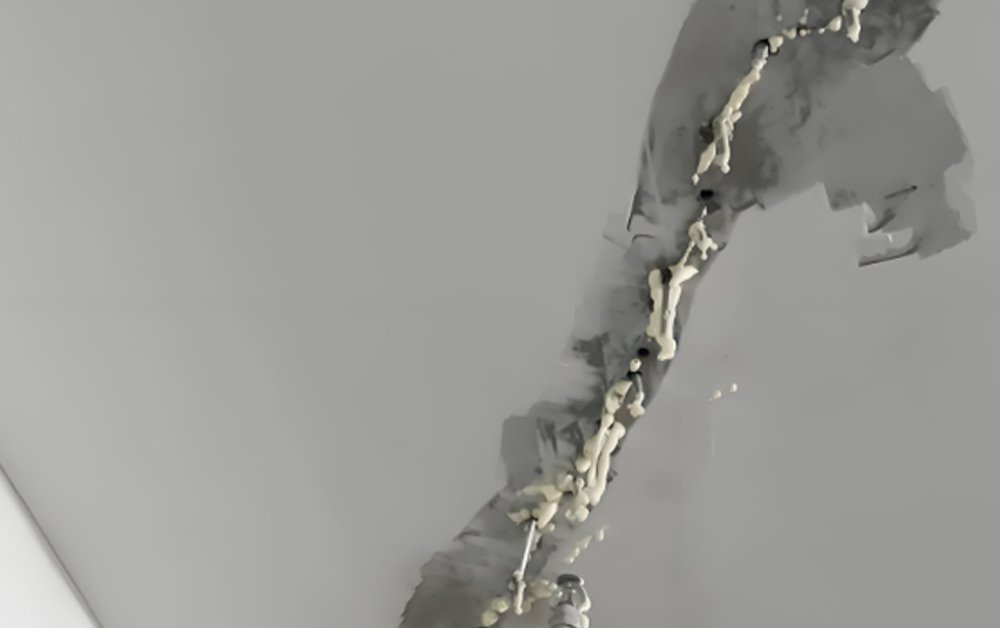

Hydrophilic polyurethane grout reacts with water by absorbing and expanding. The word hydrophilic literally means “water-loving.” This type of polyurethane injection resin actively absorbs moisture during the reaction process, allowing it to penetrate fine cracks and pores in concrete.

Once cured, hydrophilic polyurethane forms a flexible, gel-like seal that bonds strongly with concrete. It’s particularly effective in moist, low-pressure, or continuously damp environments where a long-lasting watertight seal is required.

Key Features of Hydrophilic Polyurethane Grout:

- Absorbs moisture and expands to fill voids or cracks.

- Creates a flexible and continuous waterproof gel.

- Provides excellent adhesion to wet concrete surfaces.

- Self-healing capability — can reabsorb moisture and reseal minor cracks.

- Suitable for basements, tunnels, water tanks, subways, and retaining walls.

However, hydrophilic polyurethane grout may shrink slightly if exposed to dry conditions for long periods. Therefore, it is best suited for areas with consistent moisture exposure.

What Is Hydrophobic Polyurethane Grout?

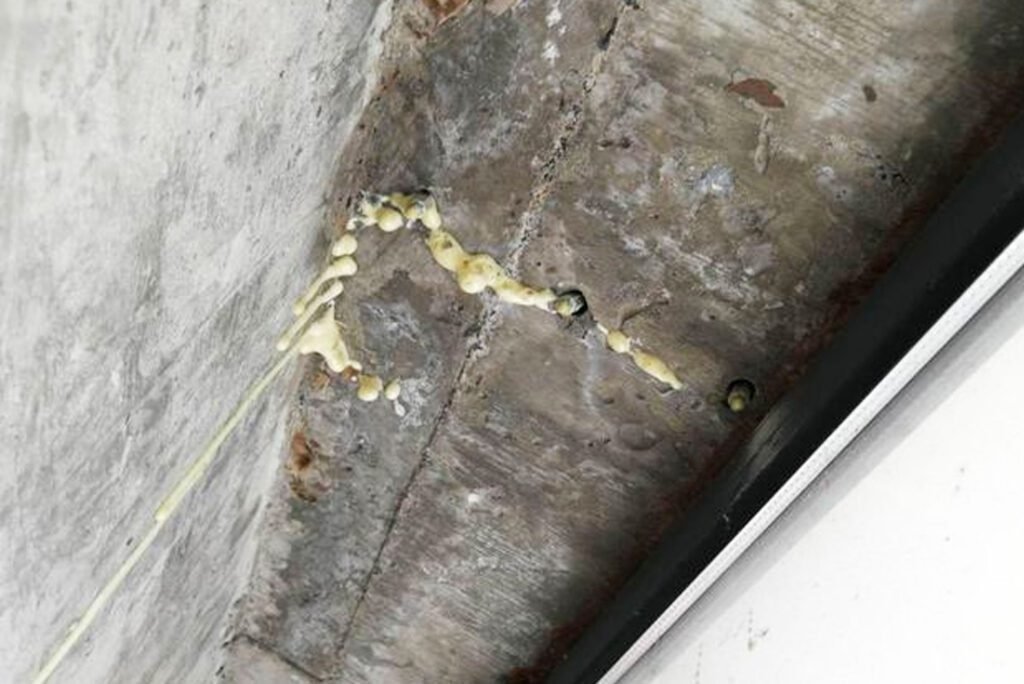

In contrast, hydrophobic polyurethane grout is “water-repelling.” When it comes into contact with water, it reacts rapidly to form a dense, closed-cell foam or solid elastomeric structure that does not absorb additional moisture.

Hydrophobic polyurethane grouts are ideal for high-pressure leaks, fast crack sealing, and emergency waterproofing repairs. They are often used where the water flow is heavy or under pressure.

Key Features of Hydrophobic Polyurethane Grout:

- Reacts quickly with minimal expansion.

- Creates a strong, rigid, and non-absorbent barrier.

- Excellent for stopping fast-flowing leaks or high-pressure infiltration.

- Forms a durable and chemically resistant waterproof seal.

- Best used in tunnels, dams, bridge decks, foundations, and structural joints.

Because of its fast curing speed and low water absorption, hydrophobic polyurethane is widely chosen for emergency repair situations where immediate leak sealing is required.

Key Differences Between Hydrophilic and Hydrophobic Polyurethane Grouts

While both materials serve the same goal — waterproofing and sealing — their properties, behavior, and applications differ significantly. Understanding these distinctions ensures that contractors choose the correct material for the job.

| Criteria | Hydrophilic Polyurethane Grout | Hydrophobic Polyurethane Grout |

|---|---|---|

| Reaction with Water | Absorbs and reacts with water | Repels water and reacts minimally |

| Flexibility | Very flexible and self-healing | Rigid and less flexible |

| Water Absorption | Absorbs moisture for sealing | Non-absorbent, forms waterproof barrier |

| Application Environment | Low-pressure or continuously damp | High-pressure or heavy leakage zones |

| Durability | Excellent for long-term moisture exposure | Excellent for instant leak control |

| Typical Use | Basements, subways, tunnels | Dams, bridges, high-flow cracks |

In simple terms:

- Hydrophilic grout is ideal for wet environments with continuous seepage.

- Hydrophobic grout is best for rapid, high-pressure leak sealing.

When to Use Each Type – Application Scenarios

Choosing between hydrophilic and hydrophobic polyurethane grout depends on your project’s environment, water pressure, and crack type.

Use Hydrophilic Polyurethane Grout When:

- The structure experiences low to moderate water pressure.

- The area remains consistently damp or humid (e.g., basements, retaining walls).

- You require long-term, flexible waterproofing with self-sealing ability.

- The goal is to form a continuous watertight barrier within porous concrete.

Use Hydrophobic Polyurethane Grout When:

- There is high-pressure water flow or severe leakage.

- You need immediate sealing performance.

- The application is in bridges, tunnels, culverts, or dams.

- A dense and durable waterproof layer is required to resist water pressure.

In Combined Systems:

Many large-scale projects use both types of polyurethane grout:

- Hydrophobic grout is first injected to stop fast-flowing water.

- Hydrophilic grout follows as a secondary injection for long-term flexibility and durability.

This dual-grouting approach delivers a reliable, permanent waterproofing solution.

How to Choose the Right Polyurethane Grout Supplier?

Selecting the right polyurethane grout manufacturer or supplier is crucial to ensure consistent quality, durability, and project success.

When sourcing from China or international suppliers, contractors should look for the following:

- Technical Capability:

The supplier should have in-house R&D teams and provide technical support for application optimization. - Quality Certifications:

Verify ISO, CE, or ASTM compliance to ensure material consistency. - Customization Options (OEM/ODM):

Leading suppliers can adjust viscosity, reaction time, and curing characteristics according to project needs. - Comprehensive Product Range:

Ensure they offer both hydrophilic and hydrophobic polyurethane grouts, plus complementary products like primers, coatings, and injection equipment. - After-Sales Service:

Technical support, data sheets (TDS, MSDS), and on-site application guidance are key for complex waterproofing projects.

Choosing a supplier that provides both product quality and engineering expertise ensures optimal performance and long-term reliability.

Why YURU Waterproof Is Your Trusted Partner for Polyurethane Grout Solutions?

As a leading manufacturer and OEM supplier in China, YURU Waterproof specializes in polyurethane grouting materials, waterproof coatings, and floor coating systems for professional engineering applications.

Our Core Strengths:

- Full Range of Polyurethane Grouts:

Including hydrophilic, hydrophobic, and microcrystalline polyurethane injection materials. - Custom OEM & ODM Services:

Tailor-made formulations for contractors, distributors, and engineering companies. - Strict Quality Control:

Each batch undergoes viscosity, gel time, and expansion ratio testing. - Export Expertise:

Products supplied to Asia, the Middle East, and Europe with reliable logistics support. - Professional Engineering Support:

Technical consulting, on-site training, and after-sales follow-up for long-term partnerships.

Whether you need rapid leak sealing or flexible waterproofing for underground structures, YURU Waterproof provides the right polyurethane grout system designed for your project’s specific conditions.

FAQs – Hydrophilic VS Hydrophobic Polyurethane Grout

What is the main difference between hydrophilic and hydrophobic polyurethane grout?

Hydrophilic grout absorbs and reacts with water to create a flexible seal, while hydrophobic grout repels water and forms a dense, rigid barrier.

Which polyurethane grout is best for basements?

Hydrophilic polyurethane grout is best for basements due to its ability to absorb moisture and form a continuous watertight layer.

Can hydrophobic and hydrophilic grouts be used together?

Yes. In many waterproofing systems, hydrophobic grout is used first for fast leak stopping, followed by hydrophilic grout for long-term sealing.

How long does polyurethane grout last?

High-quality polyurethane grout, like those made by YURU Waterproof, can last over 10 years when properly applied.

Can YURU Waterproof provide OEM or custom formulations?

Absolutely. YURU offers OEM/ODM services for polyurethane grout with customizable properties such as viscosity, reaction time, and expansion rate.

Where can I buy YURU Waterproof polyurethane grout?

Visit YURU Waterproof’s official website or contact their sales team for direct OEM and wholesale inquiries.

Conclusion

Both hydrophilic and hydrophobic polyurethane grouts play vital roles in modern waterproofing engineering. The right choice depends on project conditions, water pressure, and performance requirements.

By partnering with an experienced supplier like YURU Waterproof, contractors and distributors gain access to reliable, customizable, and high-performance polyurethane grout systems tailored to global engineering standards.

Whether for tunnel waterproofing, concrete crack repair, or basement sealing, YURU Waterproof ensures durability, flexibility, and trusted OEM quality.

YURU Product solutions

Waterproof Coating

- One-component oil-based polyurethane waterproof coating

- One-component water-based polyurethane waterproof coating

- Two-component polyurethane waterproof coating

- Two-component 6.0Mpa polyurethane waterproof coating

- Transparent Waterproof Glue

- Nano Invisible Waterproof Agent

- Silicone Waterproof Coating

- Acrylic Waterproof Coating For Metal Roof

- JS Polymer Waterproof Coating

- High Elastic Liquid Rubber Waterproof Coating

- Cement-based Penetrating Crystallization Waterproof Coating