Polyurea Grouting Material for Waterproof Engineering

- 12/20/2024

- yuruwaterproof.com

Polyurea grouting material has become an essential solution for modern construction projects, offering unparalleled waterproofing and durability. Its versatile applications, from basement sealing to tunnel leak repair, make it a top choice for engineers and contractors worldwide. In this article, we will explore the unique features, benefits, and practical uses of polyurea grouting material, along with essential tips for selecting the right supplier. Discover why YURU Waterproof is a trusted name in delivering premium-quality polyurea solutions tailored to your needs.

What is Polyurea Grouting Material?

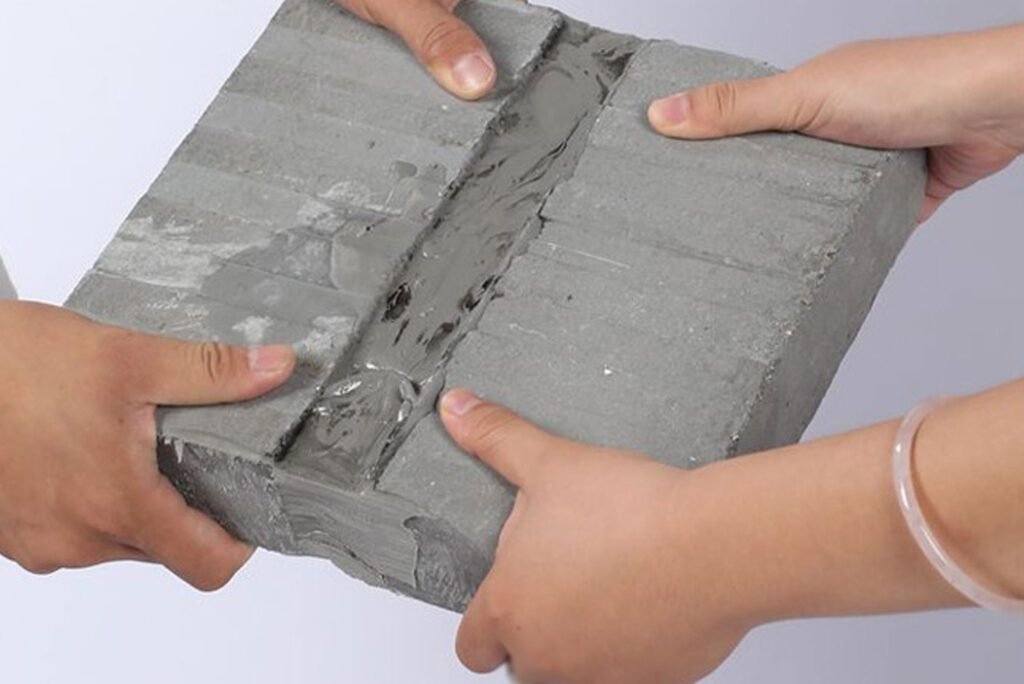

Polyurea grouting material is a cutting-edge solution widely used in construction and waterproofing projects. It is a high-performance material designed to fill cracks, seal leaks, and strengthen structures. This advanced material boasts superior properties such as high tensile strength, excellent chemical resistance, and exceptional waterproofing capabilities, making it ideal for demanding applications.

Key Features of Polyurea Grouting Material

| Feature | Description |

| High Tensile Strength | Ensures structural integrity and durability under stress. |

| Chemical Resistance | Withstands exposure to harsh chemicals, including acids and solvents. |

| Exceptional Waterproofing | Provides long-lasting protection against water ingress in challenging environments. |

| Quick Setting Time | Solidifies rapidly, reducing downtime during construction. |

| Environmental Adaptability | Performs reliably under extreme temperatures and moisture levels. |

Core Role in Construction Projects

Polyurea grouting material plays a pivotal role in modern engineering projects, particularly for:

- Sealing leaks and cracks in underground structures such as basements and tunnels.

- Strengthening weakened areas in bridges, dams, and pipelines.

- Enhancing durability in water reservoirs and swimming pools.

Comparison with Other Grouting Materials

Polyurea stands out against traditional materials like epoxy and cement-based grouts due to its versatility and performance. Unlike cement grouts, which can crack over time, polyurea maintains its elasticity and durability under dynamic conditions. Additionally, its chemical resistance makes it more reliable than epoxy in environments with high chemical exposure.

By understanding these unique properties, you can see why polyurea grouting material is rapidly gaining popularity in construction and waterproofing industries.

Applications of Polyurea Grouting Material

Polyurea grouting material is known for its versatility, making it suitable for a wide range of construction and waterproofing applications. Its ability to perform in challenging environments and provide long-term solutions highlights its value in various engineering projects. Below are the primary application areas, supported by practical examples of its effectiveness.

1. Basement Waterproofing

Polyurea grouting material is a trusted solution for sealing cracks and leaks in basements. Its waterproofing properties prevent water ingress and structural damage caused by hydrostatic pressure.

Example: In a commercial building with persistent basement flooding, polyurea grout was injected to create a watertight seal, eliminating water seepage and protecting stored assets.

2. Tunnel Leak Repair

Tunnels often face water intrusion due to underground water pressure. Polyurea grouting material ensures long-lasting leak repair while maintaining the tunnel’s structural integrity.

Example: A metro tunnel experiencing severe leaks was treated with polyurea grout, restoring functionality without disrupting transport schedules.

3. Bridge Crack Sealing

Structural cracks in bridges can compromise safety and durability. Polyurea grouting material effectively fills these cracks, preventing further damage caused by environmental factors.

Example: A highway bridge developed cracks due to heavy traffic loads. Polyurea grout was used to restore the structure’s integrity, extending its service life.

4. Swimming Pool Sealing

Swimming pools require materials that resist water pressure and chemical exposure. Polyurea grouting material provides a durable, waterproof seal that withstands chlorine and other chemicals.

Example: A luxury resort’s swimming pool with recurring leaks was treated with polyurea grout, ensuring a leak-free and safe experience for guests.

5. Pipeline Reinforcement

Polyurea grout reinforces pipelines by filling voids and cracks, preventing leaks and enhancing overall strength. This is particularly useful in industries with high-pressure fluid transport.

Example: An industrial pipeline system showed signs of wear and tear. Polyurea grouting material was applied to reinforce weak spots, ensuring uninterrupted operation.

6. Dam and Reservoir Repairs

Dams and reservoirs require robust materials to handle extreme water pressure and environmental exposure. Polyurea grouting material provides a reliable sealing and reinforcement solution.

Example: A reservoir wall with micro-cracks was repaired using polyurea grout, preventing further degradation and ensuring a stable water supply.

Benefits Across Applications

| Application | Primary Benefit | Economic Impact |

| Basement Waterproofing | Prevents property damage from water ingress | Reduces costly repairs and maintenance |

| Tunnel Leak Repair | Ensures tunnel safety and functionality | Minimizes downtime and repair costs |

| Bridge Crack Sealing | Extends structural lifespan | Avoids expensive rebuilding projects |

| Swimming Pool Sealing | Resists chemical corrosion and water pressure | Enhances guest satisfaction |

| Pipeline Reinforcement | Prevents leaks and structural failure | Ensures operational efficiency |

| Dam and Reservoir Repairs | Handles extreme water pressure and environmental stress | Secures reliable water storage |

Polyurea grouting material‘s multifunctionality and cost-effectiveness make it an indispensable choice for engineering and construction projects worldwide.

Performance Advantages of Polyurea Grouting Material

Polyurea grouting material is renowned for its superior performance across a variety of challenging conditions. Its advanced properties make it a reliable and efficient solution for demanding construction and waterproofing applications. Below, we highlight its key advantages and compare it to traditional grouting materials.

1. High Elasticity and Tensile Strength

Polyurea grouting material exhibits exceptional elasticity and tensile strength, enabling it to accommodate structural movements without cracking or losing integrity. This feature is particularly crucial in areas prone to seismic activity or heavy load shifts.

Advantage: Unlike cement-based grouts that may become brittle over time, polyurea maintains flexibility and ensures long-term durability.

2. Rapid Curing Time

One of the standout features of polyurea grouting material is its quick curing time. It solidifies in minutes, significantly reducing project downtime and allowing for faster turnaround.

Comparison: Traditional epoxy grouts often require hours or even days to cure, delaying project completion.

3. Resistance to Extreme Temperatures

Polyurea performs consistently in both high and low temperatures, making it suitable for environments with drastic climate variations.

| Temperature Range | Material Behavior |

| -40°C to 120°C | Maintains flexibility and strength |

Benefit: Unlike conventional grouts that may shrink or crack under extreme conditions, polyurea retains its properties, ensuring reliable performance.

4. Chemical Resistance

Polyurea grouting material is resistant to a wide range of chemicals, including acids, alkalis, and solvents. This makes it ideal for use in industrial environments where exposure to corrosive substances is common.

Example: Industrial tanks treated with polyurea grout have shown increased resistance to chemical erosion compared to those using epoxy-based alternatives.

5. Adaptability to Complex Environments

Polyurea can be effectively applied in diverse and challenging conditions, such as underwater, high-humidity areas, or confined spaces. Its versatility ensures it can meet the needs of various project types.

Example: Submerged pipelines repaired using polyurea grout exhibited superior adhesion and sealing compared to traditional materials.

6. Long-Lasting Durability

Polyurea’s unique composition offers excellent resistance to wear and tear, ensuring a longer service life than most conventional grouting materials.

Comparison of Durability:

| Material | Expected Lifespan | Resistance to Wear |

| Polyurea Grout | 20–30 years | High |

| Cement-Based Grout | 5–10 years | Moderate |

| Epoxy Grout | 15–20 years | Moderate |

7. Comparison with Traditional Materials

| Feature | Polyurea Grout | Epoxy Grout | Cement-Based Grout |

| Flexibility | High | Low to Moderate | Low |

| Chemical Resistance | Excellent | Moderate | Low |

| Durability | Long-lasting | Moderate | Short-term |

| Temperature Tolerance | Wide range (-40°C to 120°C) | Limited | Limited |

By leveraging these advantages, polyurea grouting material has become the go-to choice for professionals seeking reliable, efficient, and durable solutions in construction and waterproofing projects.

How to Choose High-Quality Polyurea Grouting Material?

Selecting the right polyurea grouting material is critical to ensure the success and longevity of your construction or waterproofing project. Here are key factors to consider when choosing a product, along with insights into how YURU Waterproof stands out as a reliable supplier.

1. Material Quality

High-quality polyurea grouting material should exhibit:

- Superior Strength: High tensile and compressive strength to handle heavy loads and structural stress.

- Chemical Resistance: Ability to resist corrosion from harsh chemicals like acids and solvents.

- Durability: Long-lasting performance even in challenging environments.

Tip: Always request technical data sheets and conduct quality tests before finalizing your purchase.

2. Supplier Credentials

A trustworthy supplier should have:

- Industry Certifications: Look for ISO, CE, and other relevant certifications to ensure compliance with international quality standards.

- Proven Track Record: Select suppliers with experience in the field and positive customer feedback.

Why YURU Waterproof?

With over 20 years of expertise, YURU Waterproof holds ISO 9001, ISO 14001, and CE certifications, guaranteeing reliable quality for your projects.

3. Customization Capabilities

Polyurea grouting material often needs to be tailored to specific applications. A supplier with customization services can adjust formulas, packaging, and specifications to meet your project’s unique requirements.

YURU Waterproof’s Customization Services:

| Service | Details |

| Formula Customization | Adjustments for chemical resistance, curing time, and viscosity. |

| Packaging Options | Custom labeling and packaging for wholesale orders. |

| Specification Adjustments | Tailored product properties based on environmental needs. |

4. Competitive Wholesale Pricing

Cost is an important consideration, especially for bulk orders. Look for suppliers who provide high-quality materials at reasonable prices without compromising on performance.

YURU Waterproof Advantage:

YURU offers factory-direct prices and flexible pricing options for large orders, ensuring the best value for your investment.

5. Delivery and Support Services

Reliable suppliers should ensure:

- On-Time Delivery: Efficient logistics to avoid project delays.

- After-Sales Support: Assistance with application techniques and troubleshooting.

YURU Waterproof’s Guarantee:

YURU provides comprehensive after-sales service, including technical guidance and swift delivery to ensure your project runs smoothly.

6. Key Considerations Checklist

| Factor | What to Check |

| Material Quality | Technical specifications and certifications. |

| Supplier Credentials | Experience, certifications, and customer reviews. |

| Customization Options | Ability to adapt product formulas and packaging. |

| Pricing | Competitive rates for bulk orders. |

| Delivery & Support | Reliable logistics and after-sales service. |

By considering these factors, you can confidently select the best polyurea grouting material for your project. YURU Waterproof’s expertise in customization and commitment to quality make it a trusted partner for wholesale buyers and contractors alike.

Key Considerations for Applying Polyurea Grouting Material

Proper application of polyurea grouting material is essential to ensure optimal performance and long-term results. Below are the critical construction guidelines and tips to follow during the application process.

1. Ensure Proper Mixing Ratio

Maintaining the correct mixing ratio is crucial for achieving the desired material properties. Incorrect proportions may compromise the material’s strength, flexibility, and curing time.

Guidelines:

- Follow the manufacturer’s recommended ratio strictly.

- Use precise measuring equipment for consistent results.

- Thoroughly mix until the compound achieves a homogeneous texture and color.

Tip: If unsure about the process, consult the product’s technical data sheet or seek supplier guidance.

2. Use Suitable Equipment

Polyurea grouting material requires specific tools and equipment for effective application. The right equipment ensures uniform distribution and prevents waste.

Required Equipment:

| Tool | Purpose |

| High-Pressure Pump | Ensures efficient injection into cracks or voids. |

| Mixing Device | Achieves consistent material blending. |

| Safety Gear | Protects workers from exposure to chemicals. |

Tip: Regularly inspect equipment for wear and tear to avoid application issues during construction.

3. Control Environmental Conditions

Temperature and humidity play a vital role in the performance of polyurea grouting material. Extreme conditions may affect its curing and adhesion properties.

Recommended Conditions:

- Temperature: Ideal application range is between 5°C to 35°C.

- Humidity: Avoid high-moisture environments to prevent improper curing.

- Substrate Preparation: Ensure surfaces are clean, dry, and free of debris.

Tip: Use heaters or dehumidifiers in extreme weather to create optimal application conditions.

4. Plan Injection Points Strategically

For grouting large or complex structures, plan injection points in advance to ensure even coverage and avoid material wastage.

Steps:

- Identify cracks, voids, or weak spots requiring injection.

- Mark and space injection ports at consistent intervals.

- Begin grouting at the lowest point and work upwards to displace trapped air.

5. Monitor Curing Process

Polyurea grouting material cures quickly, but monitoring is essential to ensure it achieves the desired properties.

Tips:

- Allow sufficient time for curing before applying additional coatings or loads.

- Test the material for hardness and adhesion after curing to verify quality.

6. Ensure Safety During Application

Safety is a top priority when working with chemical-based materials like polyurea grout. Follow these precautions:

- Use personal protective equipment (PPE), including gloves, masks, and goggles.

- Ensure proper ventilation in confined spaces to minimize exposure to fumes.

- Keep a first-aid kit and emergency contact numbers on-site.

Checklist for Polyurea Application Success

| Step | Action |

| Mixing Ratio | Follow precise measurements for uniform consistency. |

| Equipment | Use high-quality pumps and mixers. |

| Environmental Prep | Ensure optimal temperature, humidity, and clean surfaces. |

| Injection Points | Plan injection systematically for thorough coverage. |

| Curing Monitoring | Allow time and verify material performance post-application. |

| Safety Measures | Wear PPE and maintain proper ventilation. |

By adhering to these construction best practices, you can maximize the performance and lifespan of polyurea grouting material in any application. For expert guidance, YURU Waterproof offers detailed technical support and product recommendations tailored to your project needs.

Why Choose YURU Waterproof’s Polyurea Grouting Material?

YURU Waterproof stands out as a trusted supplier of polyurea grouting material, offering unmatched quality and service to meet the demands of global waterproofing projects. Here’s why YURU is the preferred choice for contractors and wholesale buyers worldwide.

1. Superior Product Quality

YURU Waterproof prioritizes excellence in every batch of polyurea grouting material, ensuring:

- Top-Tier Strength: With exceptional tensile and compressive properties, YURU’s materials are built for durability.

- Chemical Resistance: Resistant to harsh chemicals and environmental stressors, ideal for long-term applications.

- Reliable Performance: Consistent results across various demanding scenarios, from underground structures to industrial facilities.

Case Study: YURU’s materials have been successfully used in national-level infrastructure projects, reinforcing its reliability in large-scale applications.

2. Fast and Efficient Delivery

Time-sensitive projects require dependable supply chains. YURU ensures:

- Rapid Production Turnaround: Equipped with five advanced production lines, YURU can handle bulk orders efficiently.

- Global Shipping Expertise: Strategic partnerships with logistics providers guarantee timely delivery across the Middle East, North America, Europe, and Southeast Asia.

Example: Orders for up to 20 tons are typically shipped within 7 days, keeping clients on schedule.

3. Customization Services

Every project is unique, and YURU offers tailored solutions to match specific requirements:

| Customization Aspect | Details |

| Product Formulation | Adjustments for viscosity, curing speed, and durability. |

| Packaging Options | Custom labels, sizes, and branding for wholesale clients. |

| Technical Adjustments | Optimized formulations for extreme temperatures or chemical exposure. |

Client Feedback: “YURU’s customized solutions perfectly matched our project needs, saving us time and cost.” – A customer from Jordan.

4. Competitive Pricing for Bulk Orders

YURU offers factory-direct pricing, ensuring:

- Cost-Effectiveness: High-quality materials at affordable rates.

- Flexible Pricing Tiers: Discounts based on order volume to benefit wholesale buyers.

Comparison Table:

| Feature | YURU Waterproof | Other Suppliers |

| Price per Ton | Competitive & transparent | Higher with hidden fees |

| Customization Costs | Free for large orders | Additional charges |

| Delivery Time | 7-10 days | Often delayed |

5. Comprehensive After-Sales Support

YURU Waterproof ensures a seamless client experience with:

- Technical Guidance: Detailed application instructions and support for troubleshooting.

- Customer Service: A dedicated team to handle queries and provide solutions promptly.

- Warranty Assurance: Product performance backed by robust warranties.

6. Proven Global Reputation

YURU Waterproof has earned the trust of clients worldwide, becoming a go-to brand for waterproofing projects.

- Extensive Client Base: Partnerships with leading contractors and distributors in over 40 countries.

- Industry Recognition: ISO 9001, ISO 14001, and CE certifications highlight YURU’s commitment to quality and sustainability.

Testimonials:

“Our business has grown significantly since partnering with YURU Waterproof. Their polyurea grouting materials are unmatched in quality and affordability.” – Distributor from Saudi Arabia.

When it comes to polyurea grouting material, YURU Waterproof delivers unparalleled quality, tailored solutions, and exceptional value. Whether you’re a contractor working on a challenging engineering project or a distributor seeking reliable wholesale supplies, YURU Waterproof is your trusted partner for success.

Conclusion: Why Polyurea Grouting Material is the Best Choice for Your Projects

In conclusion, polyurea grouting material stands as one of the most versatile and reliable solutions in the construction and waterproofing industries. With its outstanding properties such as high elasticity, quick curing time, excellent chemical resistance, and adaptability to extreme conditions, polyurea is increasingly becoming the material of choice for a wide range of applications, from basement waterproofing to tunnel leak sealing and more.

By carefully selecting a high-quality polyurea product, considering factors like material strength, supplier credentials, and customization options, you can ensure the success and longevity of your projects. As highlighted throughout this article, YURU Waterproof excels in delivering top-tier polyurea grouting material with rapid delivery times, competitive pricing, and expert customization services to meet specific project needs.

With YURU’s commitment to excellence and comprehensive after-sales support, you can confidently rely on our polyurea grouting materials for superior performance in all your construction and waterproofing endeavors. Reach out to us today to learn how we can help bring your projects to life with the best-in-class solutions.

Waterproof Coating

- One-component oil-based polyurethane waterproof coating

- One-component water-based polyurethane waterproof coating

- Two-component polyurethane waterproof coating

- Two-component 6.0Mpa polyurethane waterproof coating

- Transparent Waterproof Glue

- Nano Invisible Waterproof Agent

- Silicone Waterproof Coating

- Acrylic Waterproof Coating For Metal Roof

- JS Polymer Waterproof Coating

- High Elastic Liquid Rubber Waterproof Coating

- Cement-based Penetrating Crystallization Waterproof Coating