Polyurethane Injection vs Epoxy: Which Crack Repair Material is Better?

Introduction

When it comes to crack repair in concrete structures, two of the most commonly used materials are polyurethane injection and epoxy injection. Both options offer unique advantages and are suited for different types of cracks and structural needs. Choosing the right material is essential to ensure long-term durability, prevent water infiltration, and maintain the integrity of the structure.

Polyurethane (PU) injection is known for its flexibility and water-resistant properties, making it ideal for dynamic cracks and areas exposed to moisture. On the other hand, epoxy injection provides high-strength bonding, which is crucial for restoring the structural integrity of load-bearing elements.

In this article, we will compare polyurethane injection vs. epoxy in terms of their characteristics, applications, common issues during installation, and how to choose the best option for your specific repair project.

Polyurethane Injection vs. Epoxy: Understanding the Key Characteristics

Before selecting the appropriate crack repair material, it is essential to understand the fundamental properties of polyurethane injection and epoxy injection.

Polyurethane Injection (PU) Grouting

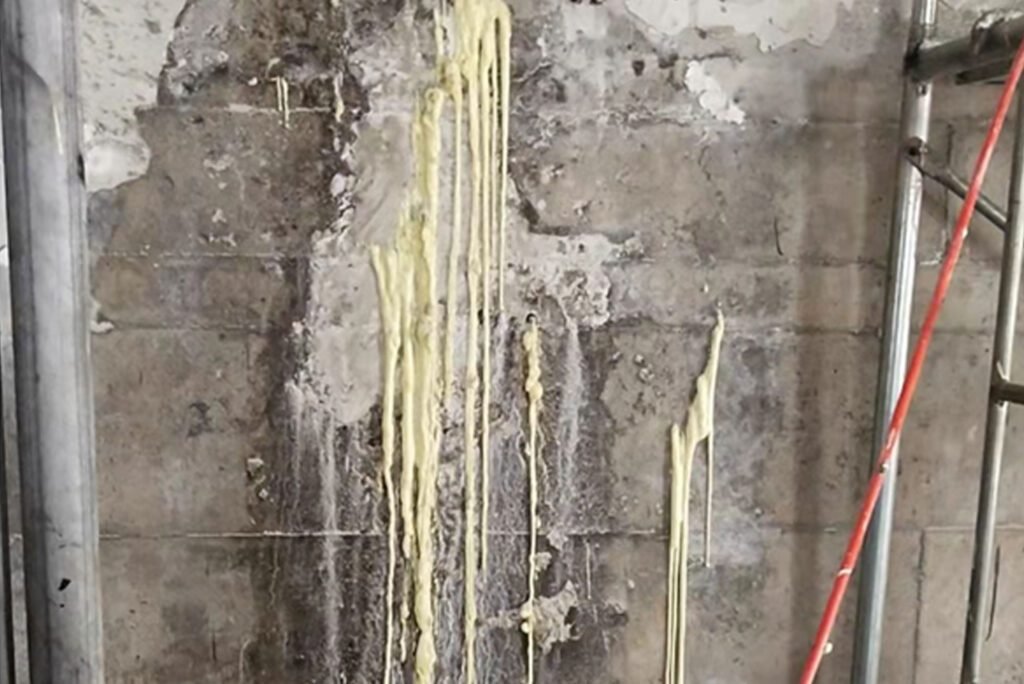

Polyurethane is a highly flexible and water-reactive material that expands upon contact with moisture. This makes it ideal for dynamic cracks and water intrusion issues. It effectively seals leaks and adapts to minor structural movements.

Epoxy Injection Grouting

Epoxy is a high-strength, low-viscosity repair material designed to restore the structural integrity of concrete. It is best suited for static cracks in load-bearing structures, providing superior bonding and durability.

Comparison Table: Key Properties of Polyurethane vs. Epoxy

| Property | Polyurethane Injection (PU) | Epoxy Injection |

| Flexibility | High flexibility, suitable for moving cracks | Rigid, best for static cracks |

| Water Resistance | Excellent, can be applied in wet conditions | Requires a dry environment, limited water resistance |

| Strength | Moderate, ideal for non-structural repairs | High, restores concrete’s load-bearing capacity |

| Application Conditions | Works well in damp or water-leaking environments | Best suited for dry, stable conditions |

| Primary Use | Waterproofing, sealing active leaks, dynamic crack filling | Structural reinforcement, bonding static cracks |

Understanding these key differences helps you choose the right material based on the specific repair needs of their project.

Application Scenarios of Polyurethane Injection and Epoxy

The choice between polyurethane injection and epoxy injection depends on the type of crack and the specific requirements of the project.

When to Use Polyurethane Injection?

Polyurethane injection is best suited for waterproofing and dynamic crack repair, especially in environments where flexibility and water resistance are essential.

- Leaking cracks in basements, tunnels, and bridges – Prevents water intrusion and adapts to movement.

- Cracks caused by foundation settlement – Provides elasticity to accommodate minor structural shifts.

- Waterproofing applications – Ideal for underground parking structures, retaining walls, and waterproofing layer restoration.

When to Use Epoxy Injection?

Epoxy injection is primarily used for structural reinforcement and static crack repair, ensuring long-term stability and load-bearing capacity.

Structural cracks in high-rise buildings and load-bearing walls – Restores concrete strength and enhances structural integrity.

Cracks that require reinforcement – Effectively bonds concrete, preventing further deterioration.

Dry environment applications – Suitable for industrial facilities, warehouse floors, and factory flooring where moisture is not a concern.

By selecting the right repair material based on the environment and structural needs, you can ensure long-lasting and effective crack repair solutions.

Common Challenges in Crack Repair Application

During the crack repair process, different materials pose unique challenges that can affect their effectiveness.

Challenges with Polyurethane Injection

- Excessive expansion – Polyurethane can over-expand after injection, leading to uneven crack sealing.

- Chemical instability in low-quality products – Some PU formulations may not fully cure due to inconsistent chemical reactions.

- Performance under high water pressure – While effective in moist environments, additional reinforcement may be needed for extreme water pressure conditions.

Challenges with Epoxy Injection

- Strictly requires a dry surface – Any moisture can significantly reduce adhesion strength.

- Long curing time – Epoxy takes longer to cure, potentially delaying construction schedules.

- Lack of flexibility – Once cured, epoxy is rigid and does not accommodate structural movement, which can lead to secondary cracking.

How to Avoid These Issues?

- Choose high-quality materials – Ensure chemical stability and proper formulation for reliable performance.

- Proper surface preparation – Clean cracks thoroughly to maximize penetration and adhesion.

- Match materials to environmental conditions – Select PU for wet conditions and epoxy for dry, stable structures to prevent repair failures.

By addressing these potential challenges, you can ensure a durable and effective crack repair process, minimizing future maintenance needs.

How to Choose the Best Crack Repair Material?

Selecting the right crack repair material depends on the specific needs of your project.

- If the crack is subject to movement or severe water infiltration → Choose Polyurethane Injection (PU).

- If the crack requires structural reinforcement and the environment is dry → Choose Epoxy Injection (Epoxy).

- For mixed crack conditions, a combination of both materials can be used for enhanced repair efficiency.

Decision Guide: Which Repair Material Should You Use?

| Issue/Requirement | Recommended Material |

| Water infiltration cracks | Polyurethane Injection |

| Structural load-bearing cracks | Epoxy Injection |

| Need for flexibility, preventing re-cracking | Polyurethane Injection |

| High-strength structural repair | Epoxy Injection |

| Wet or humid application environment | Polyurethane Injection |

| Dry application environment | Epoxy Injection |

By assessing the crack type and environmental conditions, you can ensure the most effective and durable repair solution for your project.

Why Choose YURU Waterproof’s Crack Repair Materials?

As a professional supplier of waterproofing and crack repair materials, YURU Waterproof offers high-quality Polyurethane Injection (PU) and Epoxy Injection (Epoxy) to ensure long-lasting and reliable repairs.

Our Advantages:

- Premium Quality Materials – Advanced chemical formulations ensure durability and stability.

- Competitive Wholesale Pricing – Bulk supply reduces project costs and maximizes profitability.

- Expert Technical Support – Professional guidance for material selection and application.

- Global Supply Chain – Fast logistics ensure timely project completion.

- Eco-Friendly & Safe – Low VOC emissions, compliant with international environmental standards.

YURU Waterproof provides the most effective crack repair solutions to make your projects stronger, safer, and more durable.

Conclusion

When choosing polyurethane grouting (PU) and epoxy resin (Epoxy) for crack repair, it is necessary to comprehensively consider the crack type, construction environment and repair requirements. PU is more suitable for dynamic cracks and waterproofing needs, while Epoxy is more suitable for structural reinforcement and static crack repair.

YURU Waterproof provides high-quality crack repair materials and professional services to help engineering projects be completed efficiently and safely.