Epoxy Floor Coating Supplier | YURU

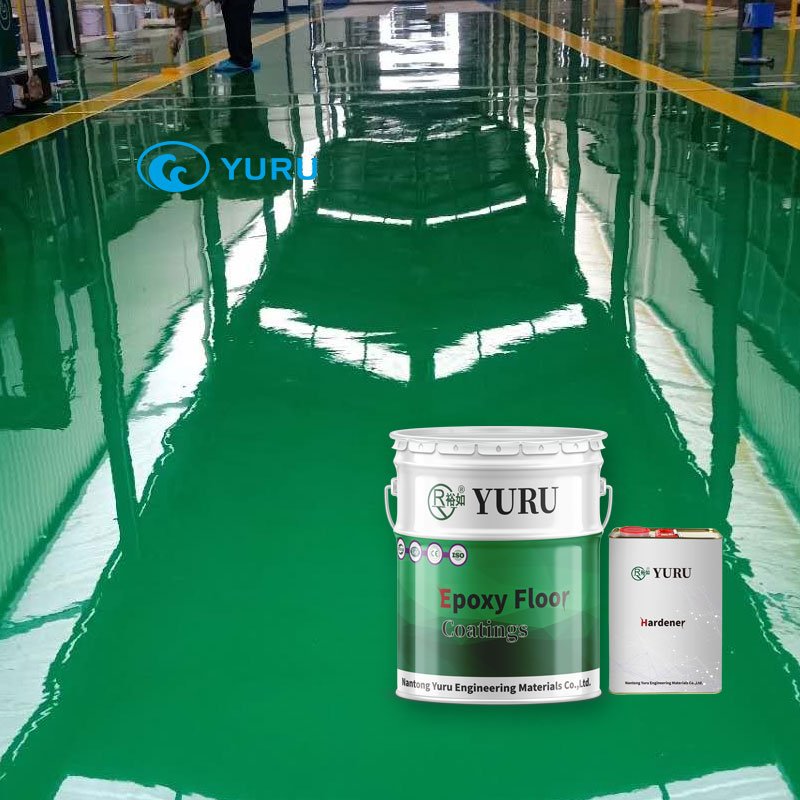

YURU Epoxy Floor Coating Solutions

YURU epoxy floor coatings deliver seamless, abrasion-resistant, waterproof solutions for factories, parking lots, hospitals, and cleanrooms. Trusted by contractors in Europe, the Middle East, and Southeast Asia.

In high-traffic environments, flooring isn’t just a surface — it’s a frontline defense against wear, chemicals, and heavy loads. YURU epoxy floor coatings are engineered for industrial and commercial performance, providing waterproof, anti-slip, and impact-resistant protection with a smooth satin finish. Epoxy floor paint uses an integral polymer surface layer, the main components of which are epoxy resin and curing agent.

Epoxy Floor Coating - Key Features & Benefits

Whether you’re resurfacing a factory floor, upgrading a garage, or delivering a commercial flooring solution for a client, our epoxy coatings offer aesthetic versatility and functional durability in one.

Excellent Weather Resistance

Resists UV, moisture, and temperature changes without cracking or fading, ensuring long-term durability indoors and outdoors.

High Compressive Strength & Anti-Slip

Withstands heavy loads and pressure while offering anti-slip surface textures to enhance on-site safety.

Strong Adhesion

Bonds tightly to concrete and cement surfaces, preventing peeling, blistering, or delamination under stress.

Abrasion & Impact Resistance

Protects against wear from traffic, tools, and machinery, maintaining surface integrity in high-use environments.

Waterproof & Chemical Resistant

Forms a seamless, impermeable layer that blocks water, oil, acids, and alkalis—ideal for demanding industrial conditions.

Mildew & Mold Resistant

Prevents fungal growth with a dense, non-porous surface—perfect for humid or hygiene-sensitive spaces.

Technical Parameters

| Property | Value |

|---|---|

| Solid Content | 100% |

| Adhesion Strength | ≥ 6 MPa |

| Impact Resistance | ≥ 70 MPa |

| Compressive Strength | ≥ 70 MPa |

Hardness (Shore hardness tester type D) | ≥ 70 |

| Cohesional Strength | ≥ 2 MPa |

| Abrasion Resistance (750g/500r) | ≤ 0.03 g |

Wash resistance, times | ≥ 10000 |

| Flame Retardancy | ≤ FH-2-45 |

| Water Resistance (48h) | No foaming or peeling |

Chemical resistance (10%H2SO4,48h/10%NaOH,48h) | Lacquer film integrity,light discolouration allowed |

Epoxy Floor Paint Applications

Garages & Parking Lots

Withstands tire wear and oil contact.

Hospitals & Cleanrooms

Seamless, hygienic, easy to clean.

Factories & Workshops

Anti-impact, abrasion-resistant.

Offices & Laboratories

Dustproof and electrostatic resistant.

Metro Stations & Commercial Zones

Slip-resistant and decorative.

Waterproof paint

Epoxy Floor Paint System & Application Process

Mixing:

Mix part A and part B as 20:5 by weight. Slowly add part B into part A and ensure mixed completely.

Thinner:

Epoxy paint thinner ≤ 10 % w./w.

Application methods:

- Airless Spray (recommended for large areas)

- Roller / Brush (for small zones)

Cautions:

Apply in good weather. The substrate temperature shall be in the range of 0- 40 ℃, and at least 3 ℃ over dew point to avoid condensation. Also, ensure apply at humidity below 85%.

Compatibility:

Primer: Epoxy Sealing Primer (30 um)

Midcoat: Epoxy Putty (1 mm, optional)

Topcoat: Self-leveling Epoxy Floor Paint (1 mm)

Take the Next Step — Partner with a Trusted Epoxy Coating Manufacturer

Why Choose YURU Waterproof?

- 20+ Years of Manufacturing Expertise

Trusted by international contractors, YURU is a factory-direct source for industrial epoxy coatings with consistent quality and reliable delivery.

- Certified Quality, Global Standards

Our coatings meet ISO and CE standards, and undergo rigorous testing to ensure high performance in real-world conditions.

- Strong R&D and Customization

From standard specifications to OEM/ODM packaging and color customization, we tailor solutions to meet your specific project needs.

- Fast Response & Export Experience

We respond to inquiries within 24 hours and provide technical datasheets, samples, and serving Europe, the Middle East, Southeast Asia, and North America.

Request a Free Quote or Sample

Transform your floor into a high-performance surface with YURU epoxy coatings — durable, seamless, and resistant to wear, water, and chemicals.

Need Help?

Frequently Asked Questions

We have compiled the most frequently asked questions about our waterproof coating paints here for your convenience, but please feel free to contact us if you have any additional questions.

What is epoxy floor coating and how does it work?

Epoxy floor coating is a durable, seamless surface system made by mixing epoxy resin and hardener. It bonds to concrete, creating a strong, waterproof, and chemical-resistant layer.

What makes YURU epoxy coatings different from other brands?

YURU offers 100% solid, industrial-grade epoxy with excellent adhesion (≥6 MPa), abrasion resistance (≤0.03g), and compressive strength (≥70 MPa). We provide OEM support, global export, and quick technical assistance.

Where can epoxy flooring be applied?

Ideal for garages, warehouses, hospitals, laboratories, shopping centers, and factories. It’s suitable for any high-traffic, heavy-load, or hygienic environment.

How long does YURU epoxy flooring take to cure?

At 23°C, it becomes touch-dry in 8 hours, walkable in 28 hours, and fully cured in 48 hours. Curing time varies based on temperature and humidity.

Is the epoxy coating slip-resistant?

Yes. YURU epoxy floors can be customized with anti-slip finishes (R9–R11) using additives or textured layers, ideal for safety-critical zones.

Can YURU epoxy floors resist chemicals and water?

Absolutely. The cured film is fully waterproof and resistant to acids, alkalis, oils, and cleaning agents—making it perfect for industrial and chemical areas.

Do you support custom colors and OEM branding?

Yes. We offer color customization (based on the RAL chart) and private label packaging to meet the needs.

How do I get technical data, pricing, or samples?

Simply fill out our inquiry form or message us via WhatsApp. We’ll respond within 24 hours with datasheets, quotations, and application recommendations. certified export packaging, and fast lead times.

Request an Instant Quote for Your Projects!

If you’ve got our products concerns and specific requirements, it’s time to speak to one of our Industry Experts. We’re glad to answer any questions you may have!

What our clients say

”From planning to delivery, it has been a smooth and gratifying transaction. The YURU Waterproof team is quickly responsive, and their products are top-grade! In the end, they deliver as promised, and more. We look forward to a long-term partnership with them.”