YURU JS Polymer Cement Waterproof Coating

Introducing JS Polymer Waterproof Coating

YURU Waterproofing is a manufacturer and factory in China that supports customized waterproof paint and injection grout.

Whether you need concrete waterproofing for a new construction or an effective waterproof polymer coating for your renovation, our JS Polymer Waterproof Coating will provide reliable, durable protection.

Polymer cement (JS) composite waterproof coating is a green and environmentally friendly waterproof coating, which is a nationally recommended residential building waterproof coating.

This JS Polymer Waterproof Coating is a two-component waterproof coating composed of organic liquid and inorganic powder. It has the dual characteristics of high elasticity of organic materials and good durability of inorganic materials. After coating, it can form a high-strength and tough waterproof coating.

Our JS Polymer Waterproof Coating is a cutting-edge polymer cement waterproof coating, specifically designed to provide strong waterproofing protection while being eco-friendly.

At the heart of our service offering is our OEM/ODM customization capability. We understand that each project is unique, which is why we offer tailored solutions for the color, packaging, and labeling of the product to align with your brand or project requirements.

However, what truly sets us apart from other suppliers is our ability to customize the performance indicators of the polymer coating for waterproofing. We can modify specific characteristics such as tensile strength, adhesion properties to meet your precise needs. Whether you’re working on a high-performance commercial project or a residential building, our polymer cement waterproof coating can be tailored for optimal performance.

Special Features

Advantages of JS Polymer Waterproof Coating

Versatile Application

◆ It can be directly constructed on a variety of wet or dry base materials without flowing on the facade.

Durable and Resilient

◆ The coating is strong, tough, water-resistant, weather-resistant and has excellent durability.

Customizable Aesthetics

◆ Pigments can be added to form a colored coating.

Eco-Friendly Formula

◆ Water-based paint, non-toxic, odorless, pollution-free and environmentally friendly.

Easy and Efficient Paint

◆ Simple construction, short construction period, can be constructed on damp base, strong bonding strength.

Breathable Coating

◆ The coating has a certain degree of air permeability, so even if the base layer is damp, the waterproof layer will not bulge.

Technical Parameters

| Item | Project | Index | ||

| I | II | III | ||

| 1 | Tensile strength/Mpa≥ | 1.2 | 1.8 | 1.8 |

| 2 | Elongation at break/%≥ | 200 | 80 | 30 |

| 3 | Low temperature flexibility(ɸ10mm) | -10℃,(No crack) | – | – |

| 4 | Water impermeability(0.3MPa,30min) | Impervious | Impervious | Impervious |

Reasons for selection

Why Choose JS polymer waterproof coating?

JS polymer waterproof coating has excellent waterproof performance, durability, environmental protection and construction convenience, as well as a wide range of applications. It is an ideal waterproof material choice in the construction field.

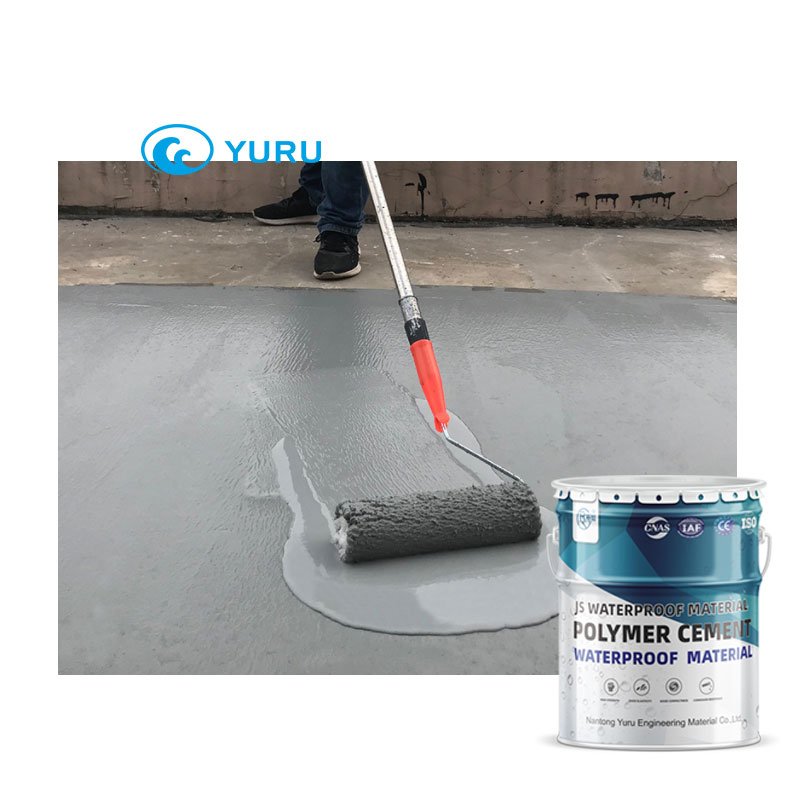

Painting method

YURU JS Polymer Waterproof Coating Construction Steps

01

Base treatment

The surface of the base should be flat, solid, free of sharp objects, floating dust, clear water, and oil stains;

The inner and outer corners and the roots of the pipes should be made into arcs, with the inner corner radius greater than 25mm and the outer corner radius greater than 5mm;

Uneven and cracked areas must be leveled first, and leaks must be plugged first.

02

Mixing materials

If water needs to be added, add water to the liquid first, and slowly add the powder while stirring with a stirrer for 5 minutes. Stir evenly until there is no lumps in the material. The prepared material should be used up within 2 hours, otherwise the increased viscosity will affect the construction.

The weight ratio method of the paint is to mix the ingredients according to the marked ratio on the product packaging. The amount of water added can be appropriate to adjust the viscosity of the paint to meet the construction of different parts of the facade and plane.

03

Additional waterproof layer for details

Fill the sealing material in the groove, and apply multiple times (2-4 times) to the inner and outer corners, pipe roots and other details. A layer of carcass reinforcement material should be added for underground projects.

04

Large surface waterproof layer construction

Large area waterproof coating should be applied multiple times, generally 4 layers, special projects can be applied 5 layers. The interval between each layer is generally 8 hours, and it should be extended in winter. The first layer of coating should be applied thinly with a thickness of 0.2-0.3mm, and the thickness of each subsequent layer should be 0.4-0.5mm.

The JS polymer waterproof coating dosage is about 0.8kg/㎡, and it should not be too thick in one layer. It is better to add no water or less water during the facade construction to prevent the coating from flowing, making it difficult for the facade thickness to reach the designed thickness, and at the same time causing the accumulation of materials at the corners to be too thick and cracks. When adding the carcass material, the carcass should be paved flat, without wrinkles, and overlapped by no less than 100mm. During construction, apply one layer of coating first, and then apply another layer of coating on top after paving. After the film waterproof layer is completed and accepted, the finished product should be protected.

Residential and Commercial Buildings

Perfect for houses, walls, basements, and more.

Infrastructure Projects

Suitable for tunnels, bridges, and reservoirs.

Interior Spaces

Ideal for bathrooms, kitchens, and water tanks.

Application

Versatile Application of JS Polymer Waterproof Coating

Unlock the potential of your projects with JS Polymer Waterproof Coating, designed for use on both wet and dry surfaces. Whether it's brick, mortar, concrete, metal, wood, hard plastic, glass, gypsum board, foam board, asphalt, rubber, SBS, APP, or polyurethane, this coating delivers exceptional performance.

Need Help?

Frequently Asked Questions

We have compiled the most frequently asked questions about our waterproof coating paints here for your convenience, but please feel free to contact us if you have any additional questions.

What is JS Polymer Waterproof Coating?

YURU JS Polymer Cementitious Waterproof Coating is two-component macromolecule water-based coating, which consists of macromolecule emulsion and cement as main raw materials. After coating, it can form a high-strength and tough waterproof coating.

How Can I Get a Quote For The Waterproof Paint?

Yes. Contact customer service today for a reasonable and precise waterproof paint quote. Include specific details including but not limited to color, quantity, packaging specifications.

What is Your MOQ For The Order?

With MOQ of only 100kg, you can ensure your order. Meanwhile we support customized orders.

What is The Turnaround Time On My Order?

It takes us around 2 to 5 business days to produce the waterproof coatings. On the other note, the transit time will take 10 to 15 business days. Reach us online for your custom and bulk orders so we can explain the actual turnaround time based on the specific details of your order.

Can I Get a Sample Before Place The Order?

Surely! You can always request a sample before place the bulk order. Sample time usually will take 2-3 days, depends on the specifications you need.

Request a sample now!

Can You Produce Specific Waterproof Paint for Us?

Yes, we can make the waterproof coating paint according to requirements to meet specific needs.

What is Your Warranty For Your Waterproof Paint?

Quality is our culture. All of our outdoor waterproof coatings are provided with a 5-year warranty. Click and learn more about our quality now.

How Long Does Waterproof Paint Last?

Yuru waterproof paints have a very long service life. The specific service life needs to be considered comprehensively based on factors such as the type of coating, construction quality, and use environment. During use, regular inspection and maintenance are also important measures to maintain the performance of waterproof coatings and extend their service life. We will recommend the most suitable product based on your use environment and situation to ensure worry-free waterproofing.

Request an Instant Quote for Your Projects!

If you’ve got our products concerns and specific requirements, it’s time to speak to one of our Industry Experts. We’re glad to answer any questions you may have!

What our clients say

”From planning to delivery, it has been a smooth and gratifying transaction. The YURU Waterproof team is quickly responsive, and their products are top-grade! In the end, they deliver as promised, and more. We look forward to a long-term partnership with them.”