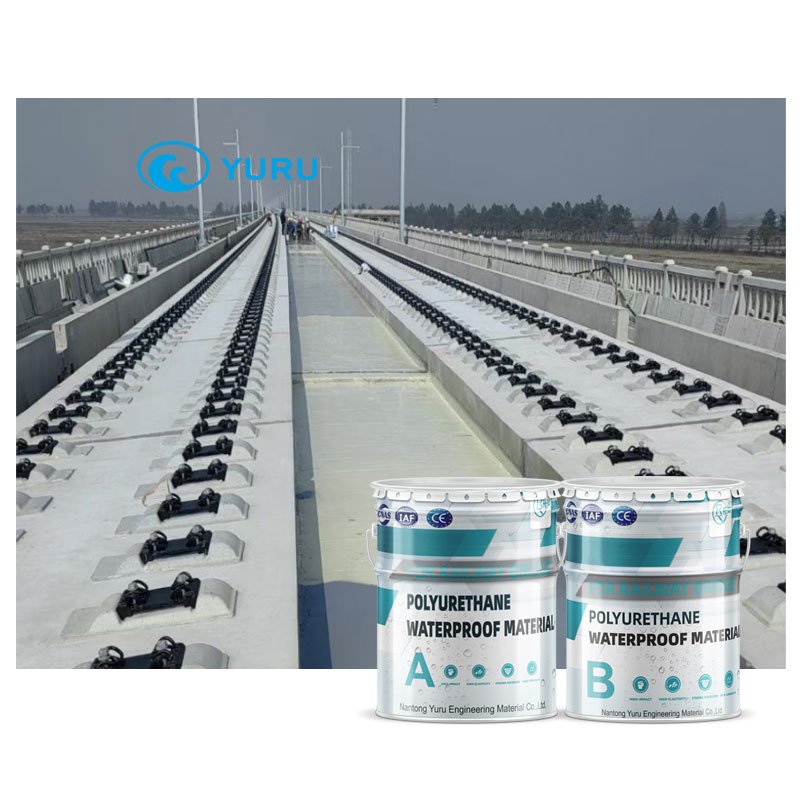

YURU Polyurethane Waterproof Coating for Railway Bridges

Polyurethane waterproof coating for railway bridges

The High-Strength Polyurethane Waterproof Coating offers robust protection for railway bridges, with features designed to withstand extreme conditions and high traffic. With easy application, weather resistance, and the ability to customize performance metrics, this product is an ideal choice for professionals working on critical infrastructure projects.

Polyurethane waterproof coating for railway bridges (for high-speed rail) is a two-component chemical reaction waterproof coating. Component A is an isocyanate-terminated prepolymer obtained by polycondensation of polyether and isocyanate. Component B is composed of reinforcing agent and plasticizer. Colored liquid composed of agents, thickeners and coagulants. When using, mix components A and B evenly in proportion, apply them on the waterproof base layer, and cross-link and solidify at high temperatures to form a rubber-like elastic coating film with high strength and high elongation.

Our OEM/ODM services offer customization options for color, packaging, and labeling, making this polyurethane waterproofing solution adaptable to your specific project or brand needs. What truly differentiates us from other suppliers is our ability to customize performance indicators such as tensile strength and elasticity. This ensures a tailored solution that precisely meets the requirements of large-scale infrastructure projects.

Special Features

Polyurethane waterproof coating for railway bridges Features

High strength

High strength, up to 6.0MPa or more; good elongation performance and excellent low temperature performance.

Overall film formation

The coating can be applied thickly, and the coating film is dense and bubble-free to form a continuous and seamless elastic waterproof layer.

Easy construction

Cold construction, construction can be carried out after components A and B are fully mixed in proportion, and the operation is simple.

Good weather resistance

Chemical reaction film formation, corrosion resistance, mildew resistance, low temperature resistance, and strong water impermeability.

Technical Parameters

Item | Project | Index |

1 | Surface drying time/h ≤ | 4 |

2 | Fully drying time/h≤ | 24 |

3 | Tensile strength/MPa≥ | 6 |

4 | Elongation at break/%≥ | 450 |

5 | Tear strength/(N/mm) ≥ | 35 |

6 | Low temperature bendability | -35℃, no cracks |

Why Choose polyurethane waterproof coating for railway bridges from YURU?

Long service life

The polyurethane waterproof coating for railway bridges can last for more than 50 years after three coats of painting.

Strong weather resistance

Railway bridge polyurethane waterproof coating has good weather resistance, can maintain stable performance for a long time under various climate conditions, and is not easy to age, crack or fall off.

Convenient construction

Railway bridge polyurethane waterproof coating is easy to construct and can be constructed by brushing, spraying, rolling, etc. The curing time is short and a waterproof layer can be quickly formed.

Support customization

We supports customized colors, packaging and other parameters to help you get products suitable for your specific purpose.

Painting method

YURU Railway bridge polyurethane waterproof coating Construction Steps

01. Clean the base surface

◇The base layer must be solid, flat, free of debris, and fully dry.

02. Two-component material mixing

◇Ingredients should be mixed according to the proportion of the two components A and B according to the construction dosage, and stirred evenly with an electric stirring rod. Additional treatment should be done on the node parts as required.

03. Paint method

◇The construction uses scraping or spraying, and the thickness is required to be uniform. The thickness is generally 1.5mm-2.5mm, and should be completed in 3-4 passes. The subsequent coating should be done after the previous coating is cured, and the direction of brushing or spraying should be perpendicular to the previous coating.

04. Post-painting treatment

◇After the acceptance of the coating film, the protective isolation layer shall be constructed according to the design requirements.

Railway bridge polyurethane waterproof coating Applications

YURU Waterproofing is a professional waterproof paint and injection grout factory and exporter. The waterproof paint and injection grout products that we manufacture is highly versatile and can be used in various different industries.

- Waterproof and moisture-proof projects such as high-speed railways, viaducts, highways, underground projects, municipal projects, pools, dams, etc.

- Used to paste waterproof membrane or directly used as waterproof layer.

- It can also be used for anti-corrosion treatment of metal equipment, pipelines, wooden boats, etc.

Need Help?

Frequently Asked Questions

We have compiled the most frequently asked questions about our waterproof coating paints here for your convenience, but please feel free to contact us if you have any additional questions.

What is polyurethane waterproof coating?

Polyurethane waterproof coating is an environmentally friendly waterproof coating that is made of an isocyanate-containing prepolymer formed by the addition polymerization reaction of isocyanate, polyether, etc., combined with a catalyst, anhydrous additives, anhydrous fillers, solvents, etc., and processed through mixing and other processes.

How Can I Get a Quote For The Waterproof Paint?

Yes. Contact customer service today for a reasonable and precise waterproof paint quote. Include specific details including but not limited to color, quantity, packaging specifications.

What is Your MOQ For The Order?

With MOQ of only 100kg, you can ensure your order. Meanwhile we support customized orders.

What is The Turnaround Time On My Order?

It takes us around 2 to 5 business days to produce the waterproof coatings. On the other note, the transit time will take 10 to 15 business days. Reach us online for your custom and bulk orders so we can explain the actual turnaround time based on the specific details of your order.

Can I Get a Sample Before Place The Order?

Surely! You can always request a sample before place the bulk order. Sample time usually will take 2-3 days, depends on the specifications you need.

Request a sample now!

Can You Produce Specific Waterproof Paint for Us?

Yes, we can make the waterproof coating paint according to requirements to meet specific needs.

What is Your Warranty For Your Waterproof Paint?

Quality is our culture. All of our outdoor waterproof coatings are provided with a 5-year warranty. Click and learn more about our quality now.

How Long Does Polyurethane Waterproof Paint Last?

The polyurethane waterproof coating can have a lifespan of 30+ years (dependant number of coats).

Request an Instant Quote for Your Projects!

If you’ve got our products concerns and specific requirements, it’s time to speak to one of our Industry Experts. We’re glad to answer any questions you may have!

What our clients say

”From planning to delivery, it has been a smooth and gratifying transaction. The YURU Waterproof team is quickly responsive, and their products are top-grade! In the end, they deliver as promised, and more. We look forward to a long-term partnership with them.”