Solve Leakage Issues with Microcrystalline Polyurea Grouting Material Solutions

Introduction: The Cost of Leakage in Construction

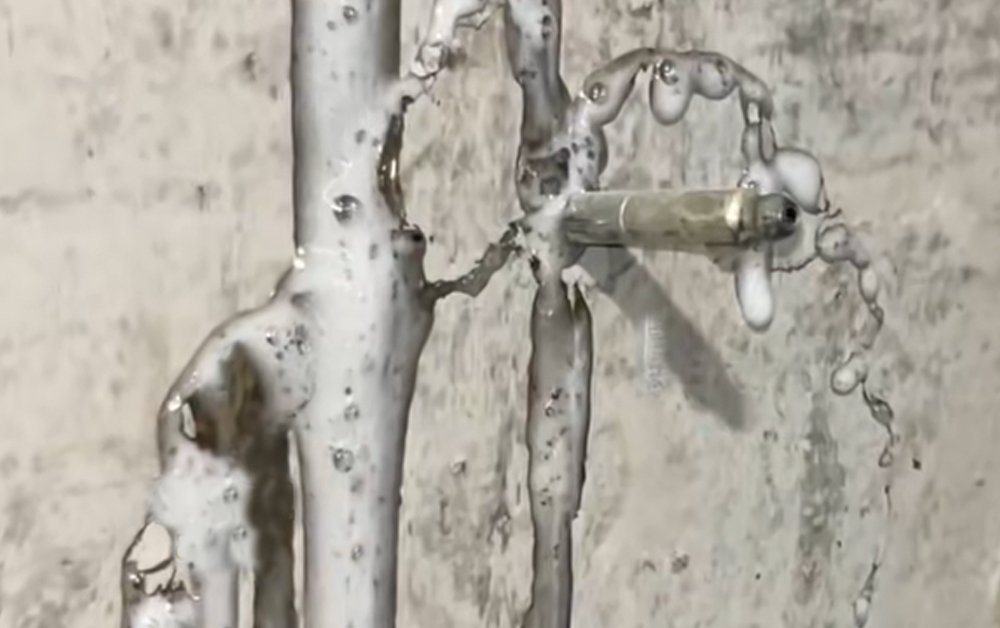

Water leakage is one of the most persistent and expensive problems in construction and infrastructure repair. It affects tunnels, subways, basements, industrial floors, and water-retaining structures, often leading to structural damage, safety risks, and escalating maintenance costs.

Traditional grouting materials frequently fail under high hydrostatic pressure, chemical exposure, and repetitive stress. Contractors and project developers are left searching for a durable, fast-curing, and adaptable solution that guarantees results.

This is where Microcrystalline polyurea grouting material solutions make a real difference.

Common Leakage Challenges in Construction Projects

1. Underground Space Leakage

Basements, tunnels, and subways are especially prone to leakage due to groundwater infiltration and constant hydrostatic pressure. Standard materials often provide only temporary results.

2. Structural Cracks and Joints

Construction joints, expansion joints, and micro-cracks are difficult to seal with conventional grouts. These vulnerable areas become repeated leakage points.

3. Poor Durability of Traditional Materials

Many grouting solutions degrade quickly under chemical attack, water erosion, or abrasion, forcing contractors into frequent, costly repairs.

4. Strict Project Timelines

Large-scale construction and repair projects typically operate on tight schedules. Materials that cure too slowly or require multiple applications can delay project completion and inflate costs.

Why Choose Microcrystalline Polyurea Grouting Material?

Exceptional Penetration

The material penetrates into the finest micro-cracks and hidden voids, creating a seamless and long-lasting waterproofing barrier.

Rapid Curing

Its fast-setting properties reduce downtime and allow projects to resume quickly, meeting even the most demanding schedules.

Durability Under Extreme Conditions

Microcrystalline polyurea resists water pressure, aggressive chemicals, and mechanical abrasion, ensuring that sealed structures remain protected for decades.

Versatile Applications

The solution is suitable for multiple environments, including:

- Underground infrastructure (tunnels, subways, basements)

- Industrial flooring and warehouses

- Water treatment plants and reservoirs

- Municipal drainage systems

Real-World Applications and Case Studies

1. Tunnel and Subway Waterproofing

A metro project faced continuous leakage at construction joints. After applying Microcrystalline polyurea grouting material, the cracks were sealed permanently, and train operations continued without disruption.

2. Municipal Drainage Systems

In one city’s drainage system, infiltration weakened concrete joints and reduced capacity. The material was injected, forming a dense, chemical-resistant seal, restoring performance during heavy rainfall.

3. Water Treatment Facilities

In a municipal water treatment plant, the clean water basin showed severe seepage. After treatment, leakage stopped entirely, reducing maintenance costs and ensuring regulatory compliance.

Beyond Materials: Delivery and Service Guarantee

High-performance material is important, but reliable delivery and technical support are equally critical in construction projects.

- Fast Supply: Flexible delivery schedules that match your project timeline.

- Technical Expertise: On-site and remote support to help contractors with application techniques.

- Quality Assurance: Each batch undergoes rigorous testing to meet international construction and safety standards.

This ensures that every project benefits from not only advanced materials but also seamless project execution.

FAQs

1: How does this material differ from traditional polyurethane grouting?

Its microcrystalline structure allows deeper penetration and higher resistance to pressure, water, and chemicals.

2: What industries benefit most from this material?

Civil infrastructure, industrial facilities, water management, and municipal engineering projects.

3: Does the material require special equipment?

No. It can be applied with standard injection grouting tools, making it accessible for most contractors.

4: What is the expected lifespan of repairs?

Properly applied, repairs can last decades, dramatically reducing long-term maintenance costs.

5: Is it environmentally safe?

Yes. The material complies with modern environmental standards and can be safely used in water-related projects.

Build with Confidence

If you’re struggling with persistent leakage issues and need a solution that is fast, reliable, and built for the long term, Microcrystalline polyurea grouting material is the right choice.

Partner with YURU Waterproof today. To explore our customized waterproofing and repair solutions.

Whether you are a contractor, developer, distributor, design consultant, or facility manager, we provide the materials, expertise, and support you need for successful project delivery.

YURU Product solutions

Waterproof Coating

- One-component oil-based polyurethane waterproof coating

- One-component water-based polyurethane waterproof coating

- Two-component polyurethane waterproof coating

- Two-component 6.0Mpa polyurethane waterproof coating

- Transparent Waterproof Glue

- Nano Invisible Waterproof Agent

- Silicone Waterproof Coating

- Acrylic Waterproof Coating For Metal Roof

- JS Polymer Waterproof Coating

- High Elastic Liquid Rubber Waterproof Coating

- Cement-based Penetrating Crystallization Waterproof Coating