Top Waterproof Coating Factories in Asia: Quality, Capacity, and Innovation

Asia has become the global backbone of waterproof coating production, supplying a massive share of polyurethane, polyurea, acrylic, cementitious waterproofing, and bitumen-based coatings used in construction projects worldwide. From mega infrastructures in the Middle East to residential renovations in Europe and South America, contractors and distributors rely heavily on Asian manufacturers for consistent supply, competitive pricing, and high-performance formulations.

This in-depth guide explores the top waterproof coating factories in Asia, evaluates their strengths, and breaks down the key factors global buyers care about most—quality, capacity, innovation, certifications, OEM/ODM capabilities, and long-term reliability. This article also highlights why YURU Waterproof has become a trusted partner for wholesalers, distributors, and engineering contractors seeking durable and cost-efficient waterproofing solutions.

1. Why Asian Waterproof Coating Factories Dominate the Global Market?

Asia’s waterproof coating industry has experienced unprecedented growth in the past decade. This expansion is driven by a combination of reliable supply chains, large-scale chemical production, and rapidly advancing material technologies.

1.1 Cost Advantage without Sacrificing Quality

Asian factories benefit from mature chemical parks, streamlined labor systems, and optimized logistics networks. These advantages allow them to maintain high product quality while offering globally competitive prices—making Asian materials a preferred option for importers and project contractors.

1.2 Wide Range of Waterproofing Technology

Asian manufacturers now lead multiple waterproofing categories, including:

- Polyurethane waterproof coatings (PU)

- Polyurea (spray & hand-applied)

- Acrylic waterproof emulsions

- Cementitious polymer coatings (JS/K11)

- Bitumen-based waterproof membranes and coatings

This broad product line allows overseas buyers to source complete waterproofing systems from a single region—or even a single factory.

1.3 Export Experience & Certifications

Most established factories in Asia comply with:

- ISO 9001 & ISO 14001 quality standards

- Performance testing

- VOC-compliant eco formulas

- CE marking requirements for Europe

This ensures compatibility with international construction standards.

2. What Quality Control Standards Top Asian Factories Follow?

High-level quality control is one of the most important concerns for wholesalers and contractors sourcing waterproof coatings from Asia.

2.1 Raw Material Selection

Factories typically use high-grade raw materials such as:

- Polyether/polyester polyols for PU

- MDI/TDI curing agents

- High-performance acrylic emulsions

- Flexibilized polymers for JS coatings

Material purity directly affects waterproof performance, adhesion, and durability.

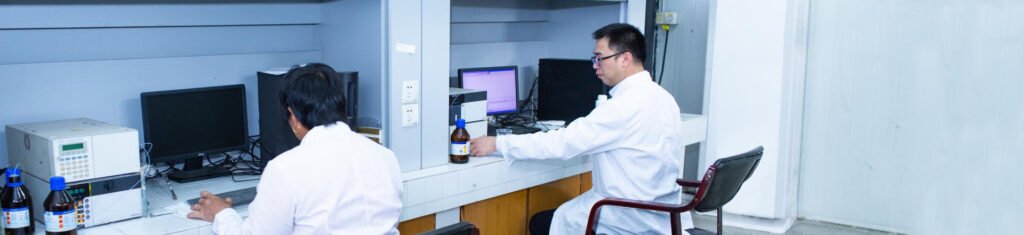

2.2 Laboratory Testing

Leading factories maintain in-house laboratories equipped for:

- Tensile & elongation testing

- Adhesion strength measurement

- Waterproof pressure testing

- UV aging simulation

- Chemical resistance testing

- Solid content & viscosity analysis

These tests ensure every batch meets consistent performance requirements.

2.3 Production Line Automation

Modern Asian facilities use semi-automated or fully automated production lines. Automatic batching systems reduce formula deviation, ensuring long-term stability across thousands of tons of production.

2.4 On-Site Batch Tracking

Factories typically adopt digital batch tracking systems that allow customers to trace:

- Production date

- Raw material batch

- Operator

- QC test result

- Warehouse entry time

This boosts transparency and accountability.

3. Comparing Production Capacity Across Asia

Different countries in Asia specialize in different aspects of waterproof material manufacturing. Understanding this helps buyers choose the right type of supplier for their needs.

3.1 China – Global Waterproofing Production Powerhouse

China has the largest waterproofing production capacity in the world.

Advantages include:

- Extremely large-scale chemical industrial parks.

- Complete supply chain.

- Strong OEM/ODM formulation customization capabilities.

- Tens of thousands of tons of annual production capacity.

- Extensive export experience.

China is the best choice for buyers seeking high volume, competitive price, and wide product lines.

3.2 Korea – Innovation & High-End Expertise

Korea is known for advanced polyurea and high-end polyurethane systems.

Features include:

- High chemical purity

- Premium-grade polyurea R&D

- Strong UV and chemical resistance formulas

Although Korean products are priced higher, they are favored in marine, bridge, and industrial applications.

3.3 Japan – Precision Chemistry & Ultra-Stable Formulas

Japan produces some of the world’s most durable and eco-friendly waterproof coatings.

Features:

- High-end environmentally friendly formula

- World-leading weather resistance

- Suitable for high-cost projects

However, production scale is limited compared to China.

3.4 India – Rapidly Growing and Cost-Friendly

India’s waterproofing industry is expanding quickly, supported by:

- Growing domestic demand

- Competitive factory pricing

- Increasing export capability

Still, their formulas and consistency are developing compared to China, Korea, and Japan.

4. Product Line Comparison: PU, Polyurea, Acrylic, Cementitious & Bitumen

Asia’s leading factories typically specialize in several advanced waterproofing types.

4.1 Polyurethane Waterproof Coatings (PU)

Widely used for:

- Rooftops

- Basements

- Parking decks

- Water tanks

- Bathrooms

Factories in China and Korea are global leaders in PU coatings.

4.2 Polyurea Waterproof Systems

Asia is the center of polyurea production, especially spray polyurea.

Common applications include:

- Bridges

- Tunnels

- Chemical storage facilities

- High-wear industrial floors

4.3 Acrylic Waterproof Coatings

Advantages:

- UV-resistant

- Flexible

- Environmentally friendly

Ideal for external walls, balconies, and sun-exposed areas

Asian factories produce large volumes of cost-efficient acrylic systems.

4.4 Cementitious Waterproof Coatings (JS/K11)

Used in:

- Basements

- Water pools

- Bathrooms

- Infrastructure

Export demand is strong due to stable performance and low cost.

4.5 Bitumen Waterproof Materials

Bitumen coatings and membranes remain popular for roofing and transportation projects.

5. How to Evaluate Whether an Asian Waterproof Coating Factory Is Reliable?

5.1 Factory Capabilities

Evaluation criteria include:

- Number of production lines

- Monthly capacity

- Equipment quality

- R&D facilities

- International project experience

5.2 OEM/ODM Service Capability

High-quality factories can modify:

- Solid content

- Viscosity

- Color

- Curing time

- Packaging

- Private-label branding

5.3 Compliance with International Standards

Essential certifications include:

- ISO 9001

- ISO 14001

- ASTM testing

- REACH compliance

- Low VOC certifications

5.4 Supplier Stability

Check:

- Delivery reliability

- Price stability

- After-sales support

- Technical documentation

- SDS availability

6. Why YURU Waterproof Is a Trusted Waterproof Coating Supplier in Asia?

YURU Waterproof stands out among Asian coating suppliers due to:

6.1 Comprehensive Product Line

YURU specializes in:

- Polyurethane waterproof coatings

- Polyurea waterproof materials

- Acrylic coatings

- JS cementitious waterproofing

- Injection grouting materials

- Floor coatings

- OEM/ODM customized waterproof systems

6.2 Strong Production Capacity

- Multiple automated production lines

- Large annual output suitable for wholesalers and engineering firms

6.3 Consistent Quality Control

Each batch undergoes comprehensive tests:

- Adhesion

- Tensile strength

- Elongation

- Water resistance

- UV aging

6.4 Export Expertise

YURU products are supplied to more than 60 countries, with stable container shipping services.

6.5 Flexible Customization

We provide formula adjustments, packaging design, branding support, and technical guidance tailored to each client’s needs.

Frequently Asked Questions

1. Are Asian waterproof coating factories reliable for long-term supply?

Yes. Many Asian factories—including China, Korea, and Japan—operate large-scale facilities with strict QC systems and strong export experience.

2. Which country offers the best prices for waterproof coatings?

China generally provides the best combination of cost, quality, and production volume.

3. Do Asian factories support OEM and private-label manufacturing?

Most leading factories, including YURU Waterproof, offer full OEM/ODM services.

4. Can Asian waterproof coatings meet ASTM or CE standards?

Yes. Many factories conduct ASTM tests and offer CE-compliant formulas for export.

5. Which waterproof coating type is most exported from Asia?

Polyurethane (PU) waterproof coating is the most exported due to its versatile applications.

6. Why is YURU Waterproof a recommended supplier for international buyers?

YURU offers high-quality coatings, stable production, customizable formulas, fast delivery, and professional technical support.

Conclusion

Asia has become the global center of waterproof coating manufacturing due to its unmatched supply chain strength, advanced technology, and competitive pricing. Whether buyers are seeking large-scale PU production, high-tech polyurea systems, or environmentally friendly acrylic coatings, Asia—especially China—offers dependable solutions for every application.

For wholesalers, contractors, and engineering project owners seeking a long-term, trustworthy partner, YURU Waterproof delivers consistent quality, reliable capacity, and flexible OEM/ODM services backed by strong technical expertise.

YURU Product solutions

Waterproof Coating

- One-component oil-based polyurethane waterproof coating

- One-component water-based polyurethane waterproof coating

- Two-component polyurethane waterproof coating

- Two-component 6.0Mpa polyurethane waterproof coating

- Transparent Waterproof Glue

- Nano Invisible Waterproof Agent

- Silicone Waterproof Coating

- Acrylic Waterproof Coating For Metal Roof

- JS Polymer Waterproof Coating

- High Elastic Liquid Rubber Waterproof Coating

- Cement-based Penetrating Crystallization Waterproof Coating