Transparent Waterproof Coating for Brick, Concrete, and Glass Surfaces

Transparent waterproof coatings have become one of the most widely used protective solutions in modern construction. Whether used on brick walls, exposed concrete structures, or sleek exterior glass elements, transparent coatings offer excellent water repellency without altering the original appearance of the building. For contractors, architects, and material distributors, understanding the performance, application conditions, and material compatibility of transparent waterproof coatings is essential for ensuring long-term durability.

This comprehensive guide explains how transparent waterproof coatings function, which substrates they are compatible with, and how to select a trusted manufacturer—especially for large-scale engineering projects.

What Surfaces Can Transparent Waterproof Coatings Be Applied To?

One of the main advantages of transparent waterproof coatings is their compatibility with a wide range of building materials. Because these coatings rely on penetrating silane/siloxane chemistry or nano-scale polymer technology, they can bond to both porous and dense surfaces.

Common Applicable Substrates Include:

Brick Surfaces

Brick walls naturally contain pores that absorb moisture. Transparent coatings penetrate deep into the brick structure, creating a hydrophobic barrier while keeping the natural color unchanged.

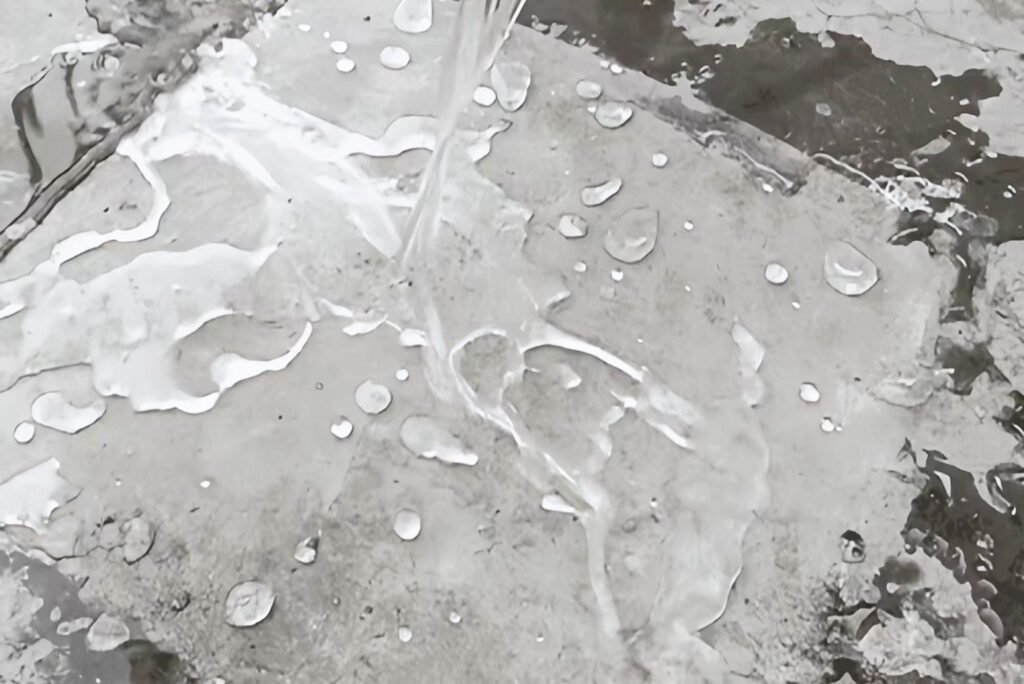

Concrete Surfaces

Concrete, especially when exposed to outdoor weathering, is prone to water absorption, efflorescence, and surface chalking. Transparent coatings protect concrete while maintaining its raw industrial look.

Glass Surfaces

For glass, the coating forms a thin, invisible film that repels rainwater and prevents water spots. It is especially useful for:

- Glass curtain walls

- Canopies

- Skylights

Other Suitable Materials

- Natural stone (granite, sandstone, marble)

- Tiles and mosaics

- Cement boards

- Decorative façades

- Outdoor sculptures and architectural elements

Because the coating does not alter color, gloss, or texture, it is ideal for projects that require both protection and aesthetics.

Performance Differences on Brick, Concrete, and Glass Surfaces

Although transparent waterproof coatings work on multiple materials, each substrate exhibits different behavior due to variations in porosity, surface energy, and density.

Performance on Brick Surfaces

Brick is highly porous, meaning it absorbs water quickly. Transparent coatings must have strong penetration ability to reach the inner capillary pores.

Key Performance Characteristics:

- Deep penetration

- Long-term water repellency

- Prevents moss and mildew growth

- Stops efflorescence

- Allows wall to “breathe” (vapor-permeable)

This makes transparent coatings ideal for restoring historical brick facades and protecting modern exterior walls.

Performance on Concrete Surfaces

Concrete surfaces vary from dense (cast-in-place) to porous (aerated concrete). A high-quality transparent waterproof coating should provide:

- Strong resistance to rainwater penetration.

- Protection against carbonation.

- Reduced dusting and chalking.

- UV and weathering resistance.

- Enhanced durability for exposed structures.

Because concrete is often used in exterior columns, beams, and exposed walls, transparent coatings offer protection without altering architectural design.

Performance on Glass Surfaces

Glass is very dense and smooth, so penetration is limited. Instead, the coating forms a micro-thin hydrophobic layer.

Performance Highlights:

- Excellent water beading

- Anti-staining

- Prevents water spots

- Improves visibility in rainy conditions

- Makes cleaning easier

This is why transparent waterproof coatings are often used for skylights, glass roofs, and curtain walls.

Core Components and Waterproofing Mechanism

Modern transparent waterproof coatings rely on advanced chemical systems. The most common types include:

Silane/Siloxane Penetrating Sealers

These penetrate into brick and concrete, chemically reacting with moisture to form a water-repellent layer within the substrate.

Acrylic or Polymer Nano-Coatings

These form a surface film that repels water while maintaining transparency.

Hybrid Systems (Silane + Polymer)

Combine penetration with surface sealing for improved durability.

How the Waterproofing Mechanism Works:

- Penetration

Small molecular structures (silane) seep into pores of brick and concrete.

- Chemical Reaction

They react with water and minerals to form a permanent hydrophobic layer.

- Surface Protection

A thin polymer layer forms on the surface, enhancing UV resistance.

- Invisible Finish

The coating remains transparent, maintaining texture and color.

The result is a long-lasting, breathable waterproofing system that suits exterior applications.

Required Construction Conditions: Temperature, Humidity, and Surface Preparation

To achieve a durable waterproofing effect, contractors must follow proper construction guidelines. Environmental conditions significantly affect adhesion and curing.

Temperature Requirements

Ideal temperature for application:

10°C – 35°C (50°F – 95°F)

Low temperatures prolong curing, while high heat may cause premature film formation.

Humidity Requirements

- Ideal humidity: 40% – 70%.

- Avoid construction on rainy or extremely humid days.

- For glass surfaces, excessive humidity may affect adhesion.

Surface Preparation

For Brick & Concrete:

- Remove dust, loose particles, oil, algae.

- Ensure surface is dry (moisture < 10%).

- Repair cracks prior to coating.

For Glass:

- Clean surface thoroughly.

- Remove fingerprints, water marks, residue.

- Ensure surface is smooth and dry.

Application Thickness & Number of Coats

Most transparent waterproof coatings require:

- 2–3 coats for porous brick or concrete

- 1–2 coats for glass

- Maintain wet-on-wet application when using penetrating sealers

Following precise guidelines ensures maximum waterproofing performance.

Common Engineering Applications for Transparent Waterproof Coatings

Transparent waterproof coatings are especially popular in modern architecture due to their ability to protect surfaces without changing appearance.

Typical Project Applications Include:

1. Exterior Brick Wall Waterproofing

For residential villas, commercial buildings, and exterior facades.

2. Exposed Concrete Structures

Including:

- Exposed walls

- Beams

- Columns

- Architectural concrete

3. Glass Canopies and Skylights

Coating ensures clarity and long-term hydrophobic protection.

4. Tile or Stone Facades

Maintains surface texture while enhancing water repellency.

5. Historical Building Restoration

Transparent coatings are widely used due to their ability to preserve the original color and texture.

6. Outdoor Structures and Landscape Design

Statues, fountains, decorative walls, and monuments.

Transparent waterproof coatings ensure both aesthetic preservation and structural durability, making them a preferred choice for high-end modern projects.

Comparison: Transparent Waterproof Coating vs. Traditional Waterproofing Materials

To help contractors choose the right product, it is important to understand how transparent coatings differ from JS coatings, acrylic waterproofing, or polyurethane coatings.

Transparent Waterproof Coating

Advantages:

- Does not change appearance

- UV resistant

- Easy to apply

- Ideal for exterior walls and exposed surfaces

- Breathable

Limitations:

- Not suitable for large cracks or areas with long-term water immersion.

- Cannot replace heavy-duty membrane systems.

Traditional Materials Comparison

vs. JS (Cementitious) Waterproofing

- JS forms a visible film; transparent coatings are invisible.

- JS is for wet rooms; transparent coatings for exterior facades.

vs. Acrylic Waterproofing

- Acrylic coatings form thicker layers.

- Transparent coatings offer better aesthetics.

vs. Polyurethane Coatings

- PU is ideal for roofs and ponds.

- Transparent coatings are better for decorative surfaces.

Each material has unique advantages depending on project needs.

How to Choose a Reliable Transparent Waterproof Coating Supplier?

Choosing the right manufacturer directly affects project durability and maintenance cost.

Below are key evaluation points for engineering contractors and distributors:

1. Product Testing & Certification

A trustworthy supplier should offer:

- UV resistance tests

- Salt spray tests

- Adhesion tests (brick / concrete / glass)

- Weathering resistance reports

2. Multi-Substrate Compatibility

High-quality coatings should work on:

- Brick

- Concrete

- Glass

- Stone

- Tiles

3. Past Engineering Case Studies

Contractors prefer manufacturers with real-world application history.

4. OEM/ODM Capabilities

Important for distributors seeking custom branding.

5. Export and Logistics Strength

Especially for overseas contractors.

Why YURU Waterproof Is Trusted Worldwide:

YURU Waterproof offers:

- Industrial-grade transparent waterproof coatings

- Strong adhesion on brick, concrete, and glass

- Anti-yellowing formula

- UV-resistant, weather-resistant materials

- Strict QC procedures

- OEM/ODM services for global distributors

- Technical guidance for contractors

YURU Waterproof has become a reliable partner for building material wholesalers, engineering contractors, and international project developers.

FAQ Section

1. Does a transparent waterproof coating change surface color?

No. A high-quality coating remains completely invisible and will not alter texture or color.

2. Can it be applied to damp brick or concrete?

Light surface moisture is acceptable for some penetrating sealers, but heavy moisture should be avoided.

3. How long does the waterproof effect last?

3–10 years depending on environmental exposure, coating type, and substrate.

4. Is the coating suitable for submerged areas?

Generally no. It is not ideal for areas such as ponds, water tanks, or drainage pits.

5. Can transparent waterproof coatings be repainted over?

Yes. They do not hinder repainting or future surface treatment.

Conclusion

Transparent waterproof coatings have become an essential protective material for modern buildings—especially those requiring both aesthetic preservation and long-term durability. Their compatibility with brick, concrete, and glass makes them suitable for a wide range of architectural applications.

For contractors, selecting a reliable manufacturer is crucial. With strong manufacturing capabilities, OEM/ODM services, and advanced coating technology, YURU Waterproof provides dependable solutions for global distributors and engineering projects.