Two-Part Epoxy Resin Grout: Best Practices for Concrete Crack Repair

Concrete cracking is one of the most common issues encountered in industrial floors, parking structures, bridges, tunnels, warehouses, and large-scale civil engineering projects. To restore structural integrity, increase load-bearing capacity, and extend service life, contractors increasingly rely on two-part epoxy resin grout—a high-strength, low-viscosity structural repair material designed to bond cracked concrete from the inside out.

This comprehensive guide explains everything contractors, engineers, and project managers need to know about using two-part epoxy resin grout for effective concrete crack repair. You’ll learn how the material works, when to use it, the correct mixing and injection procedures, and how to achieve maximum performance on site. Practical tips from manufacturers such as YURU Waterproof are also included to help professionals avoid the most common installation mistakes.

Understanding Two-Part Epoxy Resin Grout

What Is Two-Part Epoxy Resin Grout?

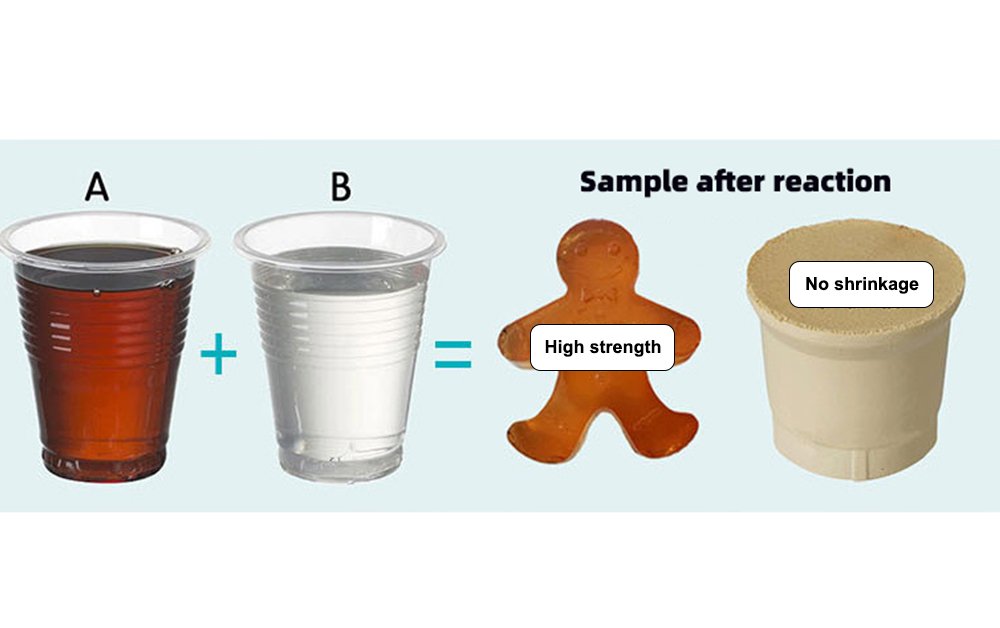

Two-part epoxy resin grout consists of:

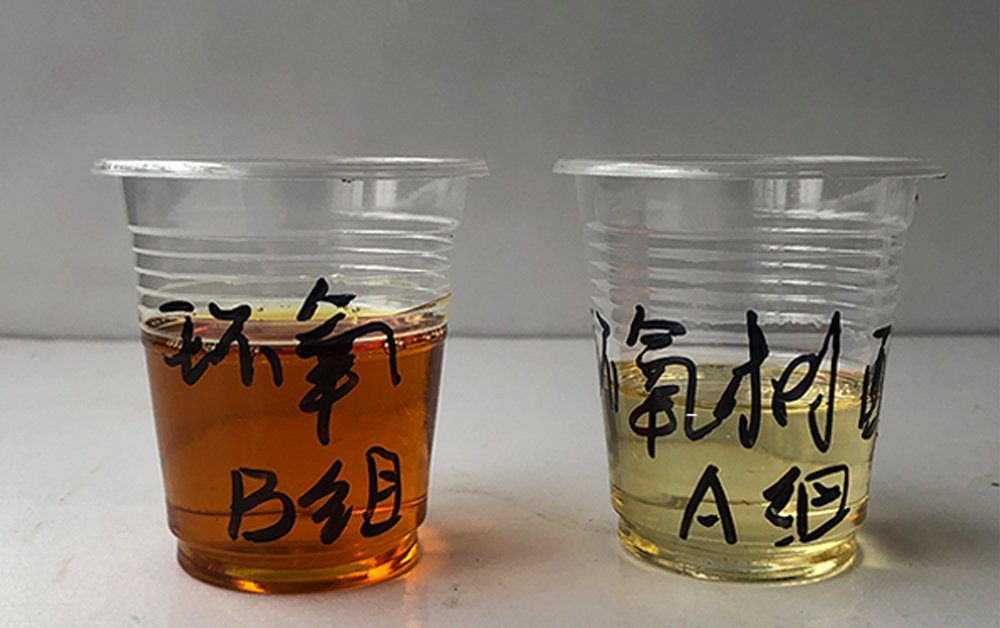

- Part A: Epoxy resin

- Part B: Hardener (curing agent)

Once mixed, the resin undergoes chemical polymerization, forming a structural adhesive much stronger than conventional repair mortars.

Key Performance Characteristics

- High compressive & tensile strength — restores original structural capacity.

- Very low shrinkage — prevents re-cracking.

- Excellent chemical resistance — ideal for factories, wastewater plants, and ports.

- Penetrates deep — suitable for hairline to medium-sized cracks.

- Highly durable — long service life, even under heavy loading.

Two-part epoxy grout is different from polyurethane chemical grouts, which expand and are commonly used for leak sealing. Epoxy is specifically chosen when the goal is structural restoration, not only waterproofing.

When to Choose Epoxy Grout for Concrete Crack Repair?

Contractors typically use epoxy resin grout when the concrete surface requires:

Structural Strength Recovery

If cracks compromise the concrete’s load-bearing performance—such as in beams, columns, or industrial floors—epoxy provides strong internal stitching and bonding.

Non-Expanding, Rigid Crack Repair

Epoxy is ideal for:

- Static cracks

- Non-moving structural cracks

- Cracks in load-bearing surfaces

- Floors that must maintain levelness

Chemical and Mechanical Durability

Industries that benefit include:

- Manufacturing plants

- Parking garages

- Tunnel systems

- Power plants

- Ports and marine structures

Deep Penetration Requirements

Low-viscosity epoxy flow allows it to enter:

- Hairline cracks

- Fine shrinkage cracks

- Deep internal fissures

Compared with polyurethane grouts, which react with water, epoxy remains stable, rigid, and long-lasting. For dry cracks needing structural recovery, epoxy is almost always the superior choice.

Surface Preparation & Crack Assessment

Proper preparation determines up to 70% of the final repair performance. The following steps ensure successful epoxy grout penetration and bonding.

Step 1: Identifying Crack Type

Contractors should determine whether the crack is:

- Structural (due to load or settlement)

- Non-structural (shrinkage, drying, temperature changes)

- Active or dormant

- Dry, damp, or leaking

Important: Epoxy should not be injected into actively leaking cracks. Water-reactive polyurethane grouts may be required first, followed by epoxy for structural reinforcement.

Step 2: Cleaning the Crack

A clean substrate ensures adhesion. Recommended cleaning techniques:

- High-pressure air blowing

- Vacuuming debris

- Steel brushing

- Removing loose particles

- Drying the crack fully

Oil, dust, or moisture significantly weakens epoxy adhesion. If the surface is contaminated, deeper cleaning may be necessary.

Step 3: Installing Injection Packers

Packers allow controlled, pressurized injection. Install them:

- At a 45° angle to reach crack depth.

- At 20–30 cm intervals along the crack.

- On both sides for deeper cracks.

Proper spacing ensures uniform resin distribution.

Step 4: Sealing the Crack Surface

Use an epoxy paste to seal the crack line. This prevents resin leakage during injection.

A smooth, sealed surface improves pressure control and ensures consistent grout penetration.

Best Practices for Mixing Two-Part Epoxy Resin Grout

The performance of epoxy grout depends heavily on how accurately it is mixed.

Mixing Ratio and Technique

Manufacturers specify a precise A:B ratio—commonly 2:1 or 3:1. Always follow product instructions.

Correct Mixing Process

- Pour Part B (hardener) into Part A (resin)

- Mix using a slow-speed electric drill (300–500 rpm)

- Scrape the container walls to ensure uniform blending

- Mix for 3–5 minutes until color becomes completely consistent

- Avoid introducing air bubbles

Never mix more epoxy than you can use within its pot life. Once polymerization begins, viscosity increases rapidly and the material becomes unusable.

Understanding Pot Life

Pot life varies depending on:

- Ambient temperature

- Material temperature

- Resin formulation

High temperatures shorten pot life. Contractors should mix smaller batches in hot conditions to avoid premature curing.

Adjusting Viscosity for Different Crack Sizes

Low-viscosity epoxy is ideal for hairline cracks, while medium-viscosity types fill wider cracks effectively.

YURU Waterproof offers customized viscosity levels for:

- Ultra-fine cracks

- General crack repair

- Deep crack injection

- High-temperature environments

Injection, Curing, and Quality Control

Correct injection procedures ensure epoxy resin reaches the full depth of the crack.

Injection Procedure

- Start injecting from the lowest packer.

- Maintain steady pressure (0.1–0.5 MPa depending on crack width).

- When epoxy appears at the next packer, close the current one and move upward.

- Continue until all packers show resin flow.

- Allow the resin to cure completely before removing packers.

Avoid injecting too quickly, which may cause poor penetration.

Curing Recommendations

Epoxy typically cures in:

- 8–12 hours (initial cure)

- 24–48 hours (full cure)

Temperature and humidity influence cure time. Protect the area from vibration, dust, or movement.

Post-Repair Inspection

Perform inspections to ensure complete crack filling:

- Tap-hammer sounding

- Core drilling on large projects

- Visual inspection for surface bonding

Professionally injected epoxy will leave no hollow sound or voids.

Common Mistakes & How to Avoid Them

Contractors commonly encounter preventable failures. Here’s how to avoid them.

1. Injecting Epoxy into Leaking Cracks

Epoxy cannot bond in the presence of water.

Solution: First inject hydrophobic polyurethane or hydrophilic polyurethane to stop leakage, then inject epoxy for structural recovery.

2. Poor Crack Cleaning

Dust, oils, or moisture cause weak bonding.

Solution: Ensure cracks are completely dry and free from contaminants.

3. Incorrect Mixing Ratio

Even minor ratio errors cause soft or brittle curing.

Solution: Measure A and B precisely, following manufacturer specifications.

4. Rushing Injection Work

Injecting too fast leads to incomplete penetration.

Solution: Maintain constant, moderate pressure.

5. Removing Packers Too Early

Premature removal leads to resin backflow.

Solution: Wait for full cure before disassembly.

Why Contractors Trust YURU Waterproof Two-Part Epoxy Resin Grout?

As a professional manufacturer supplying waterproofing, injection materials, and floor coating systems, YURU Waterproof provides premium-grade epoxy resin grouts designed for industrial and engineering demands.

Why YURU Epoxy Grouts Stand Out:

- Low-viscosity formulas for deep crack penetration

- High-strength structural bonding

- Excellent chemical and abrasion resistance

- Customizable curing speed and viscosity

- Stable performance in large-scale projects

- Strict raw material quality control

- Reliable supply for wholesalers and contractors

Recommended Applications:

- Road & bridge repair

- Tunnel and subway reinforcement

- Parking garage crack stitching

- Industrial floors & warehouses

- Dam and water conservancy structures

- Municipal concrete restoration

With YURU Waterproof, contractors receive not only materials but also technical support, mixing guidance, and on-site application suggestions.

FAQs

1. Is two-part epoxy resin grout suitable for structural cracks?

Yes. It is one of the strongest materials for structural crack restoration and bonding.

2. Can epoxy resin grout be used in wet cracks?

No. Epoxy requires dry conditions. For wet cracks, polyurethane should be injected first.

3. How long does epoxy grout last after repair?

When properly applied, the service life often exceeds 20–30 years depending on the concrete environment.

4. Can epoxy grout be used for floor leveling?

Epoxy is a bonding and crack-repair material, not a leveling system. For leveling, epoxy mortar or self-leveling compounds are recommended.

5. What is the difference between epoxy resin grout and polyurethane grout?

Epoxy is rigid and used for structural reinforcement; polyurethane is flexible and commonly used for waterproofing and leak sealing.

6. Does YURU Waterproof offer customized epoxy formulations?

Yes. YURU provides custom viscosity, curing speed, and performance formulations suited for engineering projects.

Conclusion

Two-part epoxy resin grout remains one of the most reliable, high-performance solutions for structural concrete crack repair across bridges, tunnels, industrial floors, and large-scale infrastructure. With proper crack assessment, surface preparation, accurate mixing, and controlled injection, contractors can restore durability, prevent future failure, and extend the service life of concrete for decades.

For engineering companies, wholesalers, and contractors seeking stable, high-quality epoxy materials, YURU Waterproof offers industry-trusted two-part epoxy resin grouts backed by technical expertise and consistent supply.

Whether you manage infrastructure repair, industrial flooring, or large construction projects, YURU provides dependable products designed for long-term performance.

YURU Product solutions

Waterproof Coating

- One-component oil-based polyurethane waterproof coating

- One-component water-based polyurethane waterproof coating

- Two-component polyurethane waterproof coating

- Two-component 6.0Mpa polyurethane waterproof coating

- Transparent Waterproof Glue

- Nano Invisible Waterproof Agent

- Silicone Waterproof Coating

- Acrylic Waterproof Coating For Metal Roof

- JS Polymer Waterproof Coating

- High Elastic Liquid Rubber Waterproof Coating

- Cement-based Penetrating Crystallization Waterproof Coating