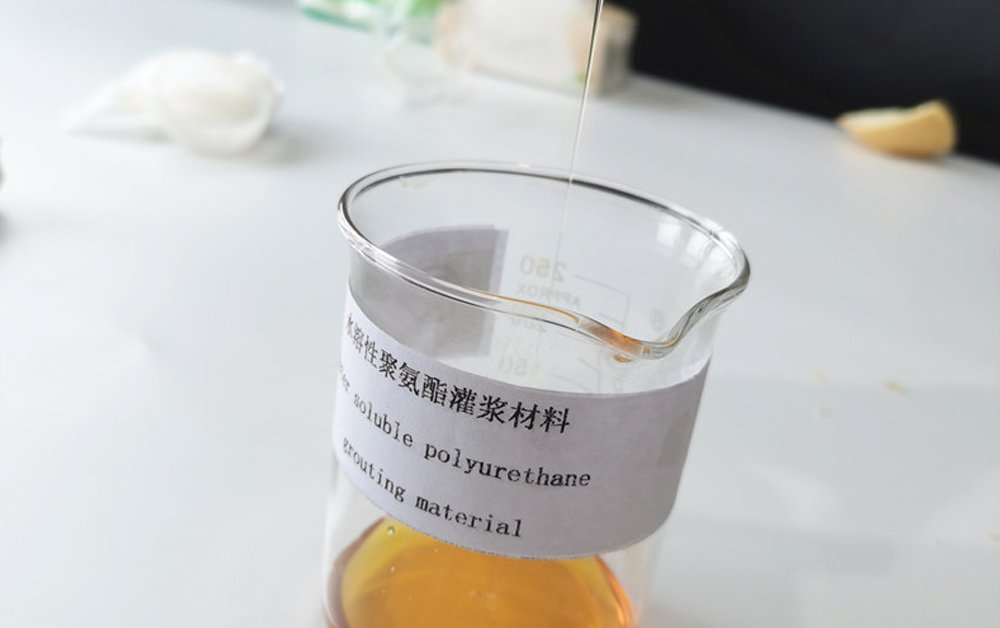

Water-Based Hydrophilic Polyurethane Grouting for Concrete Crack Repair

What is Water-Based Hydrophilic Polyurethane Grouting?

Water-based hydrophilic polyurethane grouting is a high-performance waterproofing material specifically formulated to seal active leaks, fill cracks, and protect concrete structures from water intrusion. Unlike solvent-based systems, this technology uses water as a reactive agent—a sustainable and environmentally friendly alternative that reacts with isocyanate prepolymers to form a flexible, closed-cell foam or gel.

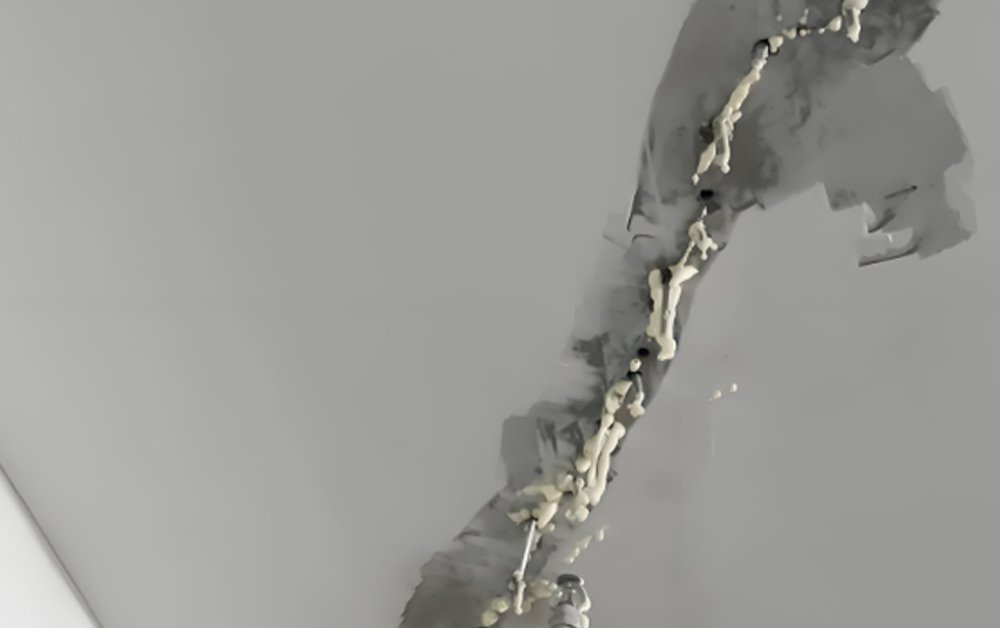

When injected into a crack or void, the hydrophilic polyurethane absorbs surrounding moisture and expands, forming a durable and watertight seal that adapts to movement and vibration within the concrete structure.

This type of grouting is widely used for structural rehabilitation, underground waterproofing, and crack sealing, offering long-term stability without compromising the strength or integrity of concrete elements.

Mechanism and Working Principle in Crack Repair

The effectiveness of water-based hydrophilic polyurethane grouting lies in its unique reaction mechanism. Upon injection into a wet or leaking crack, the material encounters water and undergoes an exothermic chemical reaction. The result is an expanding polyurethane foam or gel that tightly bonds to the concrete surface.

Key Reaction Phases:

- Injection Phase: The low-viscosity liquid penetrates even fine cracks (≤0.05 mm).

- Expansion Phase: Contact with water triggers a controlled reaction, producing CO₂ gas and expanding the polymer volume up to 10–20 times.

- Curing Phase: The foam solidifies, forming a flexible yet strong seal that remains elastic under structural stress.

- Self-Healing Property: When exposed to moisture again, hydrophilic polymers slightly re-expand, maintaining watertightness over time.

The result is a permanent waterproofing barrier that can withstand hydrostatic pressure, making it ideal for underground construction, basements, tunnels, and retaining walls.

Advantages of Water-Based Hydrophilic PU for Concrete Structures

Water-based hydrophilic polyurethane grouting provides multiple technical benefits compared to traditional repair materials like epoxy or cementitious compounds.

Key Advantages:

- Excellent Penetration and Flow: Its low viscosity allows deep infiltration into narrow and complex cracks.

- Fast Reaction and Short Downtime: Rapid curing reduces labor time and allows quick return to service.

- Superior Adhesion and Flexibility: Bonds tightly to wet concrete and adapts to micro-movements without cracking.

- Eco-Friendly and Non-Toxic: No VOC emissions, no odor, and safe for confined environments such as tunnels or basements.

- Long-Term Durability: Resistant to hydrolysis, mild acids, alkalis, and microbial growth.

- High Pressure Resistance: Withstands water pressure up to 10 bar once cured.

These combined properties make it one of the most reliable sealing technologies for civil and industrial infrastructure waterproofing projects.

Application Scenarios: Where and How to Use It

Hydrophilic polyurethane grouting is ideal for a wide range of structural waterproofing and crack-repair applications, particularly where constant water contact or moisture presence is expected.

Typical Use Cases Include:

- Concrete Crack Sealing: Seals hairline cracks, shrinkage cracks, and structural joints to prevent water ingress.

- Basement and Foundation Waterproofing: Blocks water pathways caused by capillary cracks or construction joints.

- Tunnel and Subway Waterproofing: Commonly used in underground transportation projects for long-term leak control.

- Bridge Expansion Joints: Ensures flexibility and watertight protection in structures exposed to vibration and movement.

- Reservoirs and Wastewater Facilities: Excellent resistance to continuous water pressure and chemical exposure.

Because it reacts in wet environments, no pre-drying or surface heating is required, which greatly simplifies field application.

Construction and Injection Process Guidelines

For optimal sealing performance, professional contractors should follow a systematic injection process:

1: Surface Preparation and Crack Identification

Clean and inspect the concrete surface. Remove loose materials, dust, and any contaminants. Identify the full extent of the crack or joint.

2: Drilling and Packers Installation

Drill injection ports (angled or perpendicular to the crack line) and insert metal or plastic packers. Space them evenly—typically every 15–30 cm depending on crack width.

3: Injection Process

Using a high-pressure grouting pump, inject the polyurethane slowly until resistance is felt or material appears at adjacent ports. Maintain injection pressure between 0.3–0.6 MPa.

4: Reaction and Expansion

As the material reacts with water, it expands and fills voids completely. The reaction time can be adjusted by controlling water content and ambient temperature.

5: Cleaning and Final Inspection

After curing (usually 15–60 minutes), remove packers and clean overflow material. Conduct a water pressure test to confirm sealing performance.

Following these steps ensures that the grouting system provides long-term waterproofing and structural reinforcement.

YURU Waterproof Polyurethane Grouting Solutions

At YURU Waterproof, we specialize in providing professional-grade polyurethane grouting materials designed for industrial and civil engineering applications. Our solutions combine chemical innovation, performance reliability, and environmental compliance.

Our Product Portfolio Includes:

- Water-Based Hydrophilic PU Grouting Material – Ideal for wet cracks and structural leak sealing.

- Oil-Based Hydrophobic PU Grouting System – Designed for dry conditions or heavy leakage repair.

- High-Expansion PU Foam Injection Systems – Fast-curing systems for emergency water stoppage.

- Epoxy Resin Grouting Materials—suitable for structural reinforcement and other applications.

- Customized PU Formulations – Tailor-made viscosity, expansion rates, and reaction times to suit project needs.

All YURU Waterproof products comply with ISO and CE standards and are trusted by contractors, wholesalers, and project managers across Asia, the Middle East, and Europe.

Our OEM/ODM services and technical consultation support help partners deliver reliable waterproofing performance on every project.

Why Choose YURU Waterproof as Your Engineering Partner?

YURU Waterproof stands out as a trusted supplier for high-performance waterproofing and injection systems.

Key Strengths:

- Over 20 years of R&D experience in polyurethane and waterproofing materials.

- In-house production facilities ensuring consistent quality and stable supply.

- Technical expertise in supporting contractors with on-site training and design guidance.

- Flexible customization options for different climatic and structural conditions.

- International distribution network, ensuring fast delivery and support.

YURU Waterproof — Reliable Polyurethane Grouting Solutions for Lasting Concrete Protection.

FAQ: Water-Based Hydrophilic Polyurethane Grouting

- Can hydrophilic polyurethane be used in active leaks?

Yes. It is specifically designed for wet or leaking conditions. The material reacts with water to form a watertight foam that seals the crack completely.

- How long does it take to cure?

Typically, the reaction completes within 5–15 minutes and achieves full curing in 1–2 hours, depending on temperature and moisture levels.

- Is it safe for confined environments?

Absolutely. Being water-based, it has no VOC emissions and minimal odor, making it safe for indoor and underground use.

- What is the service life of the repaired area?

When properly applied, the cured material can last over 15 years, maintaining elasticity and waterproof integrity.

- Does YURU Waterproof provide technical support?

Yes. We offer comprehensive technical assistance, from material selection to on-site application guidance and OEM customization.

Contact YURU Waterproof

For professional polyurethane grouting materials and concrete crack repair solutions, partner with YURU Waterproof — a trusted name in waterproofing innovation.

YURU Product solutions

Waterproof Coating

- One-component oil-based polyurethane waterproof coating

- One-component water-based polyurethane waterproof coating

- Two-component polyurethane waterproof coating

- Two-component 6.0Mpa polyurethane waterproof coating

- Transparent Waterproof Glue

- Nano Invisible Waterproof Agent

- Silicone Waterproof Coating

- Acrylic Waterproof Coating For Metal Roof

- JS Polymer Waterproof Coating

- High Elastic Liquid Rubber Waterproof Coating

- Cement-based Penetrating Crystallization Waterproof Coating