What Causes Concrete Cracks and How to Fix Them?

What Causes Concrete Cracks and How to Fix Them?

Concrete cracks are one of the most common challenges in construction and infrastructure maintenance. If left untreated, even minor cracks can lead to water seepage, structural failure, and costly repairs.

In this guide, we will explore the causes of concrete cracks and practical methods for fixing them—especially through epoxy and polyurethane injection techniques.

What Are the Common Types of Concrete Cracks?

Concrete cracks vary in appearance and severity. Understanding their type helps you choose the best repair method.

Plastic Shrinkage Cracks

Caused by rapid evaporation of water after pouring concrete. Usually appear as shallow, random cracks.

Settlement Cracks

Occur when the ground beneath the concrete settles unevenly. These cracks can be vertical or diagonal.

Thermal Cracks

Triggered by temperature changes that cause the concrete to expand and contract.

Structural Cracks

Indicate serious issues such as overloading or foundation shifts. These are usually wide and deep.

Hairline Surface Cracks

Fine cracks on the surface due to improper curing or finishing. May seem cosmetic but can lead to moisture ingress.

What Causes Cracks in Concrete?

Several factors contribute to crack formation in concrete:

- High Water-Cement Ratio

Excess water reduces concrete strength and increases shrinkage.

- Improper Curing

Without adequate moisture retention, concrete dries too quickly and cracks form.

- Subgrade Movement

If the soil beneath concrete is not compacted well, it shifts, causing stress.

- Thermal Expansion

Lack of expansion joints causes the concrete to crack as it expands or contracts.

- Heavy Loads

Repeated or excessive loading can exceed the concrete’s tensile capacity, causing fractures.

Prevention during design and construction is key, but timely repair is just as important.

Do All Concrete Cracks Need Repair?

Not necessarily—but some should not be ignored.

- Non-structural Cracks

Such as surface hairline cracks may be acceptable if they are not growing or allowing water ingress.

- Structural Cracks

Deep, wide, or expanding cracks may affect integrity and should be repaired urgently.

Tip: If a crack is over 0.3 mm wide or shows signs of movement or water leakage, it’s time to act.

What Are the Best Methods for Concrete Crack Repair?

Depending on the severity, different methods apply:

Epoxy Injection

Bonds cracks with high strength. Ideal for structural repairs and dry cracks.

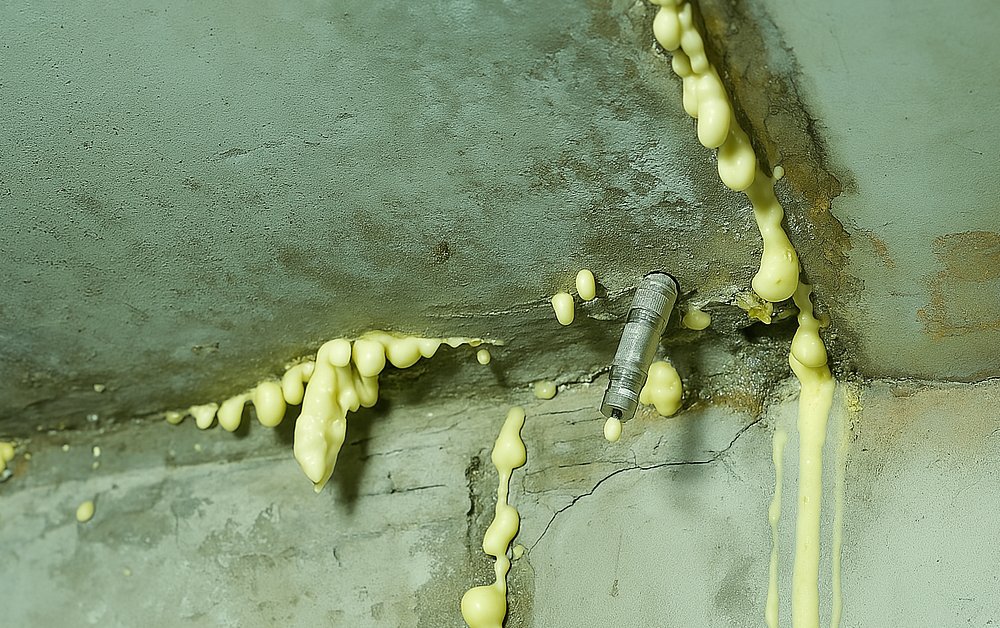

Polyurethane Injection (PU Injection)

Flexible and expands when in contact with water. Perfect for active or leaking cracks.

Routing and Sealing

Suitable for minor surface cracks. Involves enlarging and sealing the crack with flexible material.

Grouting

Often used for large voids and deep cracks. Can involve cementitious or chemical grout.

Stitching

Embeds steel reinforcement across cracks. Used in structural repairs with recurring stress.

How to Choose the Right Injection Material?

When it comes to concrete crack injection, two materials dominate: epoxy and polyurethane.

| Feature | Epoxy Injection | Polyurethane Injection |

| Strength | High tensile bonding | Moderate (focus on flexibility) |

| Flexibility | Rigid, not suitable for movement | Flexible, tolerates movement |

| Waterproofing | Minimal | Excellent, even under pressure |

| Application Condition | Requires dry cracks | Can be used in wet/leaking cracks |

| Best Use | Structural crack repair | Waterproofing dynamic, leaking cracks |

Pro Tip:

If you need structural strength, go for epoxy injection. If your crack is active or leaking, polyurethane injection is your best choice.

Need Help with Crack Injection? Contact YURU Waterproof

Whether you’re dealing with hairline cracks or structural damage, selecting the right method and materials is critical.

At YURU Waterproof, we specialize in custom concrete crack injection solutions, including:

- Epoxy and PU injection systems

- One-stop material sourcing

- OEM/ODM support for bulk orders

- Fast international delivery

Ready to repair concrete cracks effectively?

Contact us on WhatsApp or Submit an inquiry form to get expert advice and a competitive quote.

YURU Product solutions

Waterproof Coating

- One-component oil-based polyurethane waterproof coating

- One-component water-based polyurethane waterproof coating

- Two-component polyurethane waterproof coating

- Two-component 6.0Mpa polyurethane waterproof coating

- Transparent Waterproof Glue

- Nano Invisible Waterproof Agent

- Silicone Waterproof Coating

- Acrylic Waterproof Coating For Metal Roof

- JS Polymer Waterproof Coating

- High Elastic Liquid Rubber Waterproof Coating

- Cement-based Penetrating Crystallization Waterproof Coating