What is Grouting in Construction?

Introduction

In the world of modern construction, structural stability and water resistance are crucial. One of the most widely used techniques to enhance both is grouting. But what exactly does this process involve, and how can it benefit your project?

In this article, we’ll answer the question: What is grouting in construction? We’ll cover the core types of grouting materials, where grouting is used, how to identify when you need it, and why working with a specialized supplier like YURU Waterproof makes all the difference.

What Is Grouting in Construction?

Grouting in construction refers to the process of injecting a fluid-like material—commonly known as grout—into voids, cracks, or spaces between structural elements to improve stability, waterproofing, or load-bearing capacity. It plays a key role in both new construction and repair work.

There are various types of grouts used in the industry, including:

- Cementitious grouts: Used for anchoring and filling voids.

- Chemical grouts: Ideal for waterproofing and soil stabilization.

- Structural grouts: A technique for reinforcing and repairing structures by injecting grout into the interior of the structure.

The main goals of grouting include sealing leaks, reinforcing foundations, stopping water ingress, and filling structural gaps that could compromise safety.

Where Is Grouting Commonly Used in Construction Projects?

Grouting has wide-ranging applications across civil, industrial, and commercial construction. Here are some of the most common examples:

- Tunnel and subway projects — Backfill voids behind concrete linings.

- Basements and underground structures — Seal wall-floor joints and prevent leaks.

- Bridges and overpasses — Stabilize supports, anchor joints.

- Water tanks and reservoirs — Fill cracks and ensure watertight integrity.

- Soil stabilization beneath foundations — Improve bearing capacity and prevent settlement.

Each of these uses shows how critical grouting in construction is to both performance and long-term durability.

What Are the Different Types of Grouting Methods?

Choosing the right grouting method depends on the project’s goals, location, and structural condition. Here’s a breakdown of popular grouting types and their features:

| Grouting Type | Best For | Key Advantages |

| Cementitious Grouting | Anchor bolts, voids, foundation work | Inexpensive, high compressive strength |

| Chemical Grouting | Leak sealing, soil densification | Strong waterproof bonds, flexible application |

| Polyurea/Polyurethane | Cracks, dynamic waterproofing areas | Fast-curing, flexible, excellent adhesion |

| Pressure Grouting | Ground improvement, large voids | High-pressure injection, deep penetration |

| Injection Grouting | Micro-cracks, walls, tunnels | Precise control, minimal surface disruption |

By understanding the pros and cons of each method, you can make data-driven decisions rather than relying on generic materials.

How Do You Know If Your Project Needs Grouting?

Not every structural issue requires grouting—but many do. Here are common warning signs that indicate your project could benefit from professional grouting:

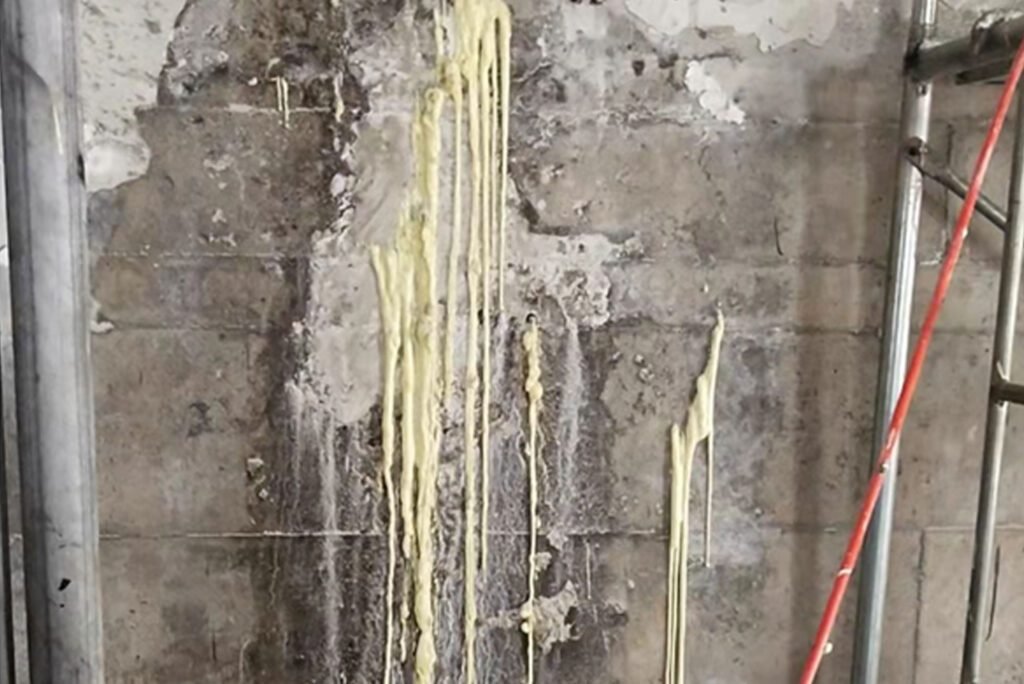

- Visible cracks in concrete or wall surfaces

- Water seepage through joints or expansion gaps

- Hollow sounds when walking over slabs

- Shifting or settling foundations

- Evidence of corrosion near structural joints

If you notice any of these signs, it’s best to consult a grouting expert to assess the site and recommend the right product and method.

🔍 Need help evaluating your site? YURU Waterproof offers free initial consultations and custom solution planning.

Why Choose YURU Waterproof as Your Grouting Materials Partner?

When it comes to sourcing high-quality grouting solutions, YURU Waterproof brings deep industry knowledge, customizable product lines, and technical expertise to the table. Here’s why we’re trusted by contractors and engineering firms worldwide:

- Wide product range: All types of chemical grouting.

- Technical consulting: We provide solution design and formula matching.

- Customized formulations: Tailored to your substrate, leakage condition, and curing time.

- Bulk supply & logistics: Scalable support for both small jobs and infrastructure megaprojects.

- Reliable performance: Proven in tunnels, bridges, basements, and critical waterproofing systems.

Whether your project is a tunnel, a foundation retrofit, or a waterproofing upgrade, our team is here to support you with precision, performance, and reliability.

Conclusion

So, what is grouting in construction? It’s more than a technique—it’s a vital solution that ensures safety, durability, and waterproof integrity in a wide range of structures. From foundation stabilization to crack sealing and leak prevention, grouting plays a critical role in modern engineering.

If you’re planning a project and aren’t sure what type of grout or method is right, let the experts at YURU Waterproof help. We provide technical guidance, custom products, and reliable delivery to keep your work on time and on spec.

📩 Ready to get started?

Contact us today to discuss your project and discover the best grouting solution tailored to your needs.

YURU Product solutions

Waterproof Coating

- One-component oil-based polyurethane waterproof coating

- One-component water-based polyurethane waterproof coating

- Two-component polyurethane waterproof coating

- Two-component 6.0Mpa polyurethane waterproof coating

- Transparent Waterproof Glue

- Nano Invisible Waterproof Agent

- Silicone Waterproof Coating

- Acrylic Waterproof Coating For Metal Roof

- JS Polymer Waterproof Coating

- High Elastic Liquid Rubber Waterproof Coating

- Cement-based Penetrating Crystallization Waterproof Coating