What is Grouting in Construction? – Types and Advantages

Introduction

Grouting is a critical process in the construction and waterproofing industry that enhances structural integrity, controls water infiltration, and fills voids in both soil and concrete. From underground tunnels to high-rise foundations, grouting plays a important role in protecting and strengthening built environments.

In this article, we explain what grouting is, explore the different types of grouting used in construction, introduce popular chemical materials (including innovative solutions like microcrystalline polyurea grout), and highlight the benefits and applications of grouting in real-world projects.

What is Grouting and Why Is It Important in Construction?

Grouting is the process of injecting fluid material—called grout—into gaps, cracks, cavities, or joints in a structure. Once the grout sets, it forms a solid, durable mass that either reinforces the structure or blocks the movement of water and air.

Key purposes of grouting include:

- Sealing water leaks in concrete or masonry.

- Strengthening foundations or retaining walls.

- Filling voids to prevent soil erosion or settlement.

- Stabilizing loose ground or rock.

- Repairing structural cracks in bridges, tunnels, and dams.

Whether it’s used for waterproofing or structural repair, grouting is a vital technique for extending the lifespan and performance of buildings and infrastructure.

What Are the Common Grouting Methods Used in Construction?

Grouting methods vary depending on the purpose, structure type, and site conditions. The most commonly used methods include:

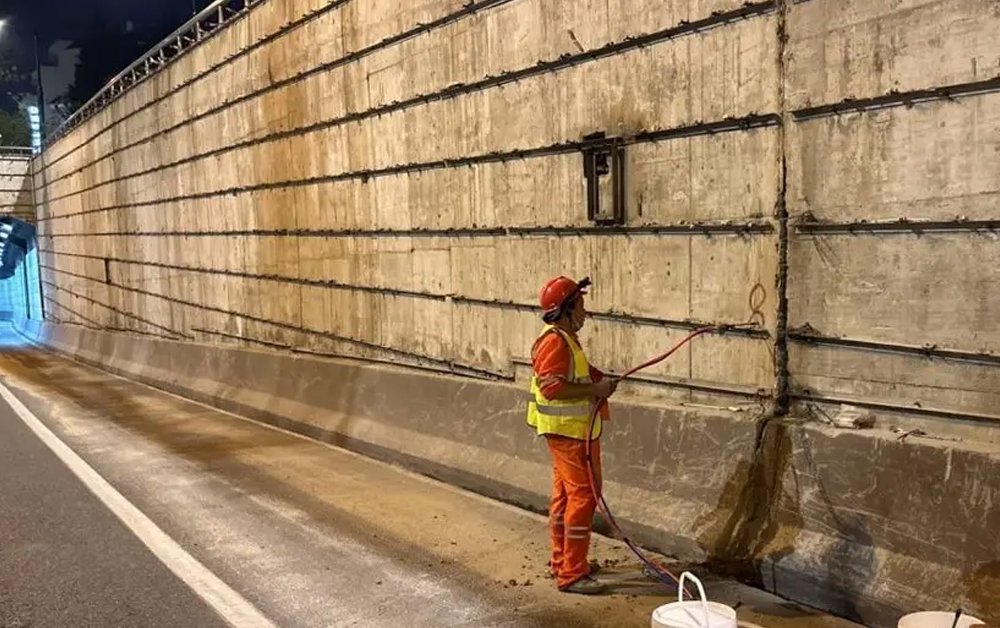

- Crack Injection Grouting: Used to repair fine to moderate cracks in concrete structures with flexible or rigid grout materials.

- Curtain Grouting: Creates an impermeable barrier behind walls or slabs to prevent water ingress, often used in underground or dam structures.

- Consolidation Grouting: Strengthens soil or loose rock by injecting grout to fill voids and bind particles together.

- Contact Grouting: Fills gaps between structural elements (e.g., tunnel linings and ground) to ensure uniform load distribution.

- Compaction Grouting: Displaces and densifies loose soil by injecting stiff grout under high pressure, improving ground load capacity.

Each technique has its own benefits and is selected based on engineering needs, site access, and environmental considerations.

What Types of Grouting Materials Are Used and When?

Selecting the right grouting material is crucial for project success. Here are the most widely used chemical grouts and their ideal applications:

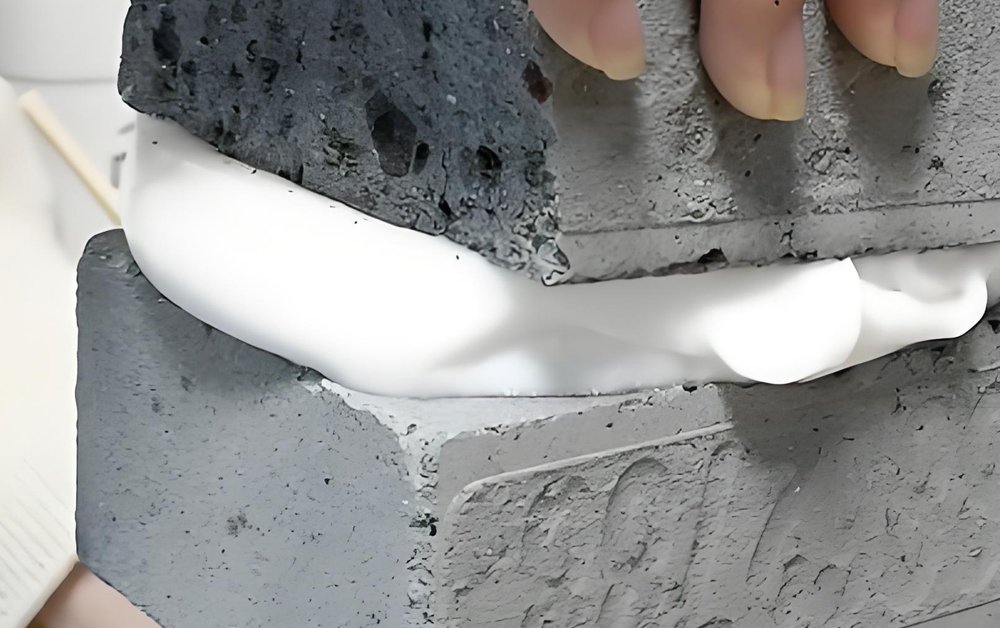

Cementitious Grout

- Made from cement and water or additives.

- Used for large-volume void filling, slab lifting, and base stabilization.

- Cost-effective but not suitable for very fine cracks.

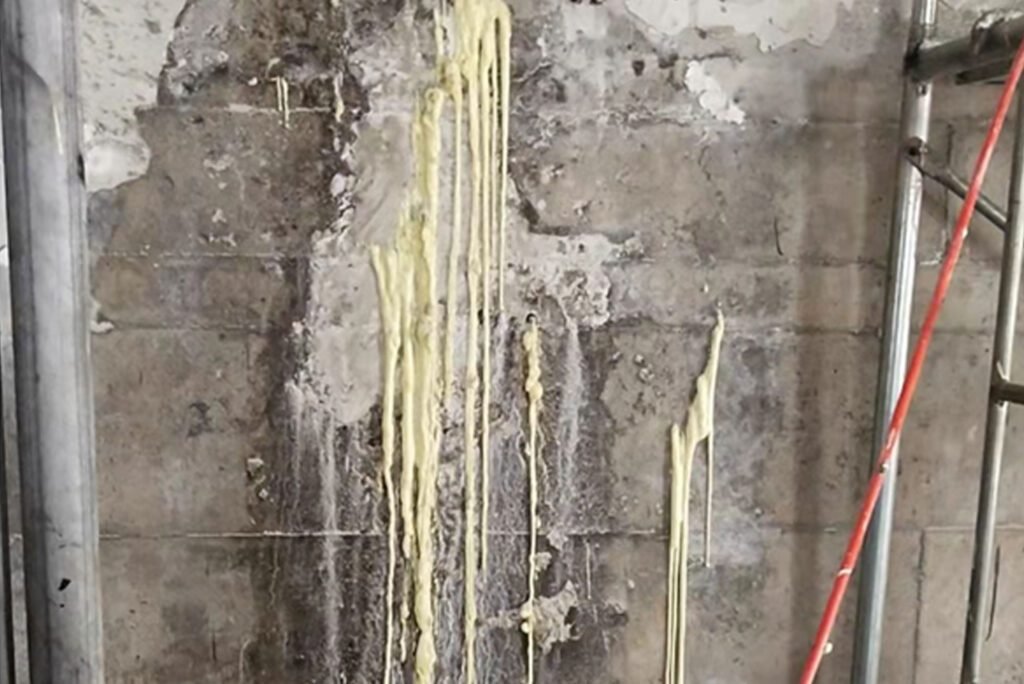

Polyurethane (PU) Grout

- Reacts with water to expand and seal leaks.

- Highly flexible, fast-reacting, and ideal for wet conditions.

- Commonly used in basements, tunnels, and retaining walls.

Epoxy Grout

- Two-component resin system offering high compressive and bond strength.

- Used for structural crack repair and restoring load-bearing capacity.

- More expensive, suitable for dry, critical structural areas.

Acrylic (Acrylate) Grout

- Very low viscosity, capable of penetrating microcracks and fine soils.

- Suitable for curtain grouting and deep soil injection.

- Quick-setting, with excellent chemical and water resistance.

Microcrystalline Polyurea Grout

- A next-generation waterproofing solution with rapid curing, high elasticity, and superior resistance to chemicals and temperature variations.

- Excellent for long-term durability in complex environments like tunnels, water tanks, subways, and high-load foundations.

- Offers longer lifespan and stronger adhesion compared to traditional PU.

Each material serves a unique function, and professional selection based on conditions such as crack size, water pressure, and structural movement is essential.

What Are the Advantages of Grouting in Modern Construction?

Grouting offers a wide range of engineering and operational benefits, making it indispensable for both new builds and renovations:

Strengthens and stabilizes weak soils or structures.

Effectively stops active water leaks.

Adapts to narrow or complex construction areas.

Reduces the need for major structural replacement.

Extends the lifespan of concrete and underground infrastructure.

Provides fast, targeted intervention with minimal downtime.

Its flexibility, cost-effectiveness, and compatibility with multiple construction materials have made grouting a go-to solution across civil engineering sectors.

How YURU Waterproof Provides Efficient Grouting Solutions for Your Project?

At YURU Waterproof, we specialize in delivering comprehensive grouting materials and systems tailored to your project’s challenges. We support you with:

- A full range of grouting materials, including PU, microcrystalline polyurea, acrylic, epoxy, and cementitious grouts.

- Custom formulations based on project requirements (e.g., reaction time, viscosity, chemical resistance).

- Technical consulting and support to ensure optimal application.

- Fast delivery and bulk supply capabilities for engineering-scale operations.

- Sample kits and training to help you evaluate and apply our systems efficiently.

Whether you’re repairing water ingress in a tunnel or stabilizing a foundation, our team provides trusted products and expert guidance for effective and lasting results.

Conclusion

Grouting is much more than crack repair—it’s a vital method for strengthening, sealing, and stabilizing the modern built environment. With materials like polyurethane and microcrystalline polyurea offering advanced durability and performance, it’s essential to choose the right grouting system for each application.

Need help selecting the best grouting material for your project?

Contact YURU Waterproof today for expert recommendations, tailored formulations, and professional-grade materials that deliver real-world results.