What Is the Difference Between Acrylate and PU Grouting Materials?

Introduction:

In underground waterproofing and structural leak repair, few topics generate more confusion than the choice between acrylate grouting materials and polyurethane (PU) grouting materials.

Both are widely used in tunnels, basements, dams, and civil infrastructure. Both are referred to as “chemical grouts.” The selection of these two materials in actual construction projects requires careful consideration, as their applications are not interchangeable.

This article will explain the true differences between acrylate and polyurethane grouting materials, from their chemical reactions to their on-site performance.

1. Understanding the Material Fundamentals: Different Chemistry, Different Roles

First, the reaction and curing methods of polyurethane grouting and acrylate grouting are different.

Acrylate Grouting Material: Water-Based Elastic Gel

Acrylate grouting material is a two-component material that can react when mixed alone or when mixed with water. After mixing, they form a low-viscosity liquid that can penetrate into extremely fine cracks, capillaries, and porous substrates.

After the reaction, the material transforms into a flexible, hydrophilic gel.

Key features include:

- Extremely low initial viscosity.

- Excellent micro-crack penetration.

- Forms a continuous elastic gel network.

- Able to absorb water and maintain flexibility for a long time.

In short, the design concept of acrylate grouting material is to penetrate along the water flow path and seal from the inside, rather than forcibly blocking the water flow.

Polyurethane (PU) Grouting Material: Reactive Expansion System

Polyurethane grouting materials work differently. Depending on the formulation, they react with water to form two states:

- Expanding foam (hydrophobic polyurethane)

- Elastic solid resin (hydrophilic polyurethane)

Polyurethane systems rely on rapid chemical reactions and volume changes. When water is present, gas generation leads to expansion, physically blocking the leak.

Key features include:

- Fast reaction speed

- High expansion rate

- Strong initial sealing effect

- Higher mechanical strength after curing

Polyurethane is essentially a reactive sealing material, not a penetration-based system.

2. Leakage Control Logic: Rapid Flow Blocking vs Deep Sealing

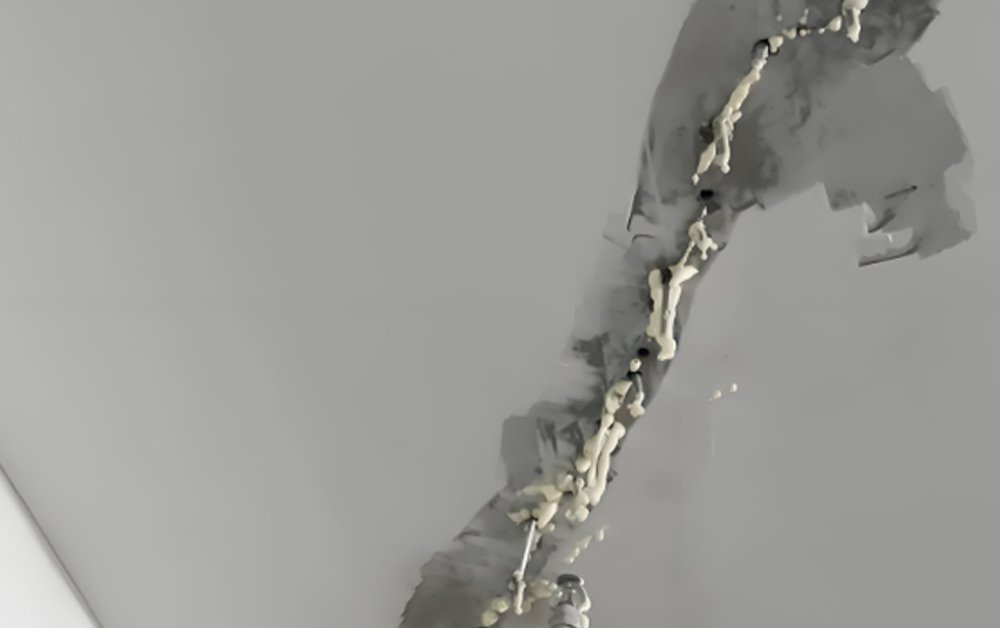

PU Grouting: Immediate Leak Stoppage

PU excels when the problem is active water flow:

- Pressurized water jets

- Sudden groundwater ingress

- Visible running water

The expansion reaction allows PU to quickly occupy voids and physically block water movement. This makes it ideal for emergency leak control.

However, this strength is also a limitation. PU seals where it reacts, not necessarily throughout the entire water migration network.

Acrylate Grouting: Long-Term Sealing of Water Paths

Acrylate systems focus on penetration before reaction. The grout follows moisture pathways, spreads laterally, and forms a flexible gel that seals entire zones rather than single points.

This makes acrylate particularly effective for:

- Chronic seepage

- Wide-area dampness

- Construction joints and cold joints

- Curtain grouting behind structures

In practice, acrylate addresses the cause of leakage, while PU addresses the symptom.

3. Construction Performance: Reaction Control, Equipment, and Risk

From a contractor’s perspective, material performance on site matters more than laboratory data.

PU Grouting on Site

Advantages:

- Rapid response

- Immediate results

- Minimal waiting time

Challenges:

- Reaction speed requires experience

- Risk of over-expansion

- Potential for blocking injection ports

- Difficult to control in fine cracks

PU grouting demands precise timing and skilled operation. Errors often result in wasted material or incomplete sealing.

Acrylate Grouting on Site

Advantages:

- Adjustable gel time

- Excellent controllability

- Low injection pressure

- Minimal structural stress

Challenges:

- Slower visible results

- Requires patience

- Needs careful proportioning

Acrylate grouting is more forgiving but requires process discipline rather than speed.

4. Application Scenarios: When to Choose Acrylate or PU?

There is no universal solution. Selection depends on leak type, structure, and project goals.

PU Grouting Is Better When:

- Water pressure is high.

- Leaks are active and localized.

- Emergency intervention is required.

- Immediate water stoppage is critical.

Typical applications:

- Sudden tunnel leaks

- Active cracks in basements

- Construction-stage emergencies

Acrylate Grouting Is Better When:

- Leakage is persistent but slow.

- Seepage occurs over wide areas.

- Long-term durability is required.

- Structural movement is expected.

Typical applications:

- Tunnel lining curtain grouting

- Dam foundation sealing

- Underground walls with chronic dampness

In many professional projects, both materials are used together, not separately.

5. Durability and Structural Adaptability

Short-term sealing success does not equal long-term waterproofing.

PU Durability Considerations

PU materials can become relatively rigid over time, especially hydrophobic foams. In structures with movement, this rigidity may lead to micro-gaps reopening.

PU is best viewed as a structural stopgap or a primary barrier in stable conditions.

Acrylate Durability Considerations

Acrylate gels remain elastic and hydrated. They tolerate:

- Micro-movements

- Thermal cycles

- Long-term moisture exposure

For infrastructure designed to last decades, acrylate often provides better lifecycle performance.

6. How to Evaluate a Reliable Grouting Material Supplier?

Material selection is only as good as the supplier behind it.

A reliable supplier should:

- Clearly explain application limits.

- Offer both acrylate and PU systems.

- Provide test data and case references.

- Support sample trials and site-specific advice.

Suppliers who promote a single “universal material” often oversimplify complex engineering problems.

7. YURU Waterproof: A System-Based Grouting Approach

At YURU Waterproof, we do not promote acrylate and PU as competing products.

Instead, we treat them as complementary tools within a complete grouting strategy.

In many municipal and underground projects, our recommended approach is:

- Hydrophobic or hydrophilic PU grouting for rapid leak control.

- Acrylate grouting for deep penetration and long-term sealing.

This layered methodology has proven effective in tunnels, subways, basements, and dam structures across multiple climates and groundwater conditions.

FAQs:

Selecting the best Polyurea coating for your project depends on several factors. Here are a few key considerations to help you make an informed decision:

1. Can acrylate grouting stop active water leaks?

It can, but it works best after water flow is reduced. For heavy flow, PU is usually applied first.

2. Is PU grouting permanent?

PU provides strong immediate sealing, but long-term performance depends on structural movement and material type.

3. Which material is better for tunnels?

Most tunnel projects use both—PU for emergency control, acrylate for curtain sealing.

4. Does YURU supply both systems?

Yes. YURU provides hydrophobic PU, hydrophilic PU, and acrylate grouting systems with technical support.

Conclusion:

The real difference between acrylate and PU grouting materials is not strength, speed, or price. It is purpose.

- PU controls water immediately

- Acrylate controls water permanently

Understanding this distinction allows engineers and contractors to stop repeating repairs and start delivering durable waterproofing solutions.

Contact YURU Waterproof for project-specific grouting recommendations, technical data, and sample support.