Where to Find Waterproof Coating Suppliers for Tunnels and Metro Projects?

Tunnel and metro construction presents some of the harshest waterproofing challenges in civil engineering. Constant groundwater pressure, chemical exposure, and structural movement mean that standard architectural coatings simply aren’t enough.

Finding reliable waterproof coating suppliers for tunnels and metro projects requires more than comparing product catalogs — it demands technical validation, engineering experience, and OEM customization capacity. This article explores how to identify qualified suppliers, evaluate coating systems, and why YURU Waterproof stands out as a trusted partner for infrastructure waterproofing worldwide.

1. Understanding the Unique Waterproofing Challenges of Tunnels and Metro Projects

Tunnels and metro networks operate under extreme environmental stress. Unlike above-ground structures, they face continuous hydrostatic pressure, temperature variations, and limited maintenance access. This means the waterproofing system must be both durable and self-sustaining over decades.

Key challenges include:

- High groundwater pressure that can exceed several bars, leading to microleakage or water seepage.

- Soil chemical attack — sulfates, chlorides, and pH variations can degrade coatings.

- Concrete movement and cracking due to temperature and load changes.

- Difficult access — post-construction repairs are costly and disruptive.

Because of these risks, modern tunnel waterproofing strategies rely heavily on high-performance coatings such as polyurea, polyurethane, and epoxy systems that form seamless, elastic membranes. Contractors today are shifting from purely membrane-based waterproofing to spray-applied coating systems for faster installation, stronger adhesion, and greater flexibility.

2. Key Performance Requirements for Tunnel and Metro Waterproof Coatings

To ensure structural safety and longevity, coatings used in tunnels and metro environments must meet demanding specifications. The most critical parameters include:

- Adhesion strength – Strong bond to concrete, steel, and shotcrete surfaces to prevent delamination.

- Water impermeability – Resistance to both positive and negative hydrostatic pressure.

- Elongation and crack bridging – Flexibility to accommodate structural movement without cracking.

- Chemical resistance – Protection against acids, salts, and biological agents in groundwater.

- Abrasion and impact resistance – Essential for service tunnels, maintenance zones, and rail interfaces.

- Temperature and humidity tolerance – Stable curing and performance under variable climate conditions.

- VOC and environmental compliance – Low-VOC or water-based systems for confined underground environments.

Contractors evaluating suppliers should always request test data such as tensile strength, adhesion, elongation, and permeability. Suppliers that can provide independent third-party certifications (SGS, CE, ISO) signal greater reliability.

3. Types of Waterproof Coating Systems Used in Tunnel and Metro Construction

There is no “one-size-fits-all” coating for underground projects. Each section of a tunnel may require a different formulation. Below are five major waterproof coating families used worldwide:

3.1 Polyurea Waterproof Coating

Polyurea systems are widely adopted in tunnels due to their rapid curing, high elasticity, and excellent abrasion resistance. They can be spray-applied to form seamless membranes even on complex geometries.

- Advantages: Fast curing, strong adhesion, chemical and UV resistance.

- Applications: Tunnel linings, metro station roofs, underground parking areas.

- OEM Customization: YURU Waterproof provides modified polyurea systems optimized for variable humidity and application temperature.

3.2 Polyurethane (PU) Waterproof Coating

PU coatings offer a perfect balance between flexibility and strength. They can bridge cracks and adhere strongly to concrete or metal substrates.

- Advantages: Excellent elongation, UV stability, and weather resistance.

- Applications: Structural joints, tunnel expansion sections, retaining walls.

- OEM Customization: YURU can adjust viscosity, curing rate, and hardness for on-site spray or brush applications.

3.3 Epoxy Waterproof Coating

Epoxy systems deliver high compressive strength and chemical resistance but are less flexible. They are ideal for protective coatings rather than primary membranes.

- Applications: Technical rooms, equipment zones, tunnel floors, maintenance galleries.

3.4 Cementitious Waterproof Coating

Cement-based systems are widely used for substrate protection and as a base layer before applying elastomeric coatings.

- Advantages: Cost-effective, breathable, and easy to apply.

- Applications: Tunnel interiors, pump rooms, and backfill surfaces.

3.5 Grouting and Injection Waterproofing Systems

Grouting materials (PU or acrylate-based) are used for active leak sealing and joint waterproofing.

- Applications: Crack repair, segment joints, and high-pressure leakage zones.

- OEM Customization: Adjustable gel time, viscosity, and expansion ratio to suit various geological conditions.

Each of these systems can be tailored through YURU’s OEM service to align with regional standards, equipment compatibility, and specific contractor requirements.

4. How to Evaluate and Choose Reliable Waterproof Coating Suppliers?

Selecting the right waterproof coating supplier is as critical as choosing the coating system itself. Infrastructure projects demand partners with proven technical and manufacturing credibility.

Key supplier evaluation criteria include:

- Engineering references – Experience with metro, tunnel, and hydropower projects.

- Certifications – ISO9001, ISO14001, CE, SGS reports.

- OEM capability – Ability to customize formulations and packaging.

- Technical support – On-site guidance and troubleshooting assistance.

- Quality control – Batch traceability, testing documentation, and consistency.

- Logistics and delivery reliability – Stable raw material sourcing and global shipping capability.

YURU Waterproof is recognized for its engineering-grade product quality, automated production lines, and comprehensive technical documentation. The company’s internal R&D and export experience allow it to meet diverse compliance standards for both domestic and international metro projects.

5. Why OEM Customization is Critical for Large Tunnel and Metro Projects?

Large infrastructure projects are rarely uniform. Different sections — such as shield tunnels, cross passages, and ventilation shafts — may require different coating chemistries and thicknesses.

OEM customization ensures:

- Formula optimization for specific curing conditions (humidity, temperature).

- Equipment compatibility with contractor spray machines.

- Compliance with local standards (low-VOC, environmental regulations).

- Color-coding and labeling for safety identification.

- Cost efficiency by aligning material output with project schedules.

By partnering with an OEM supplier like YURU Waterproof, contractors gain access to flexible production planning, private-label branding, and consistent quality assurance, ensuring both project performance and long-term brand trust.

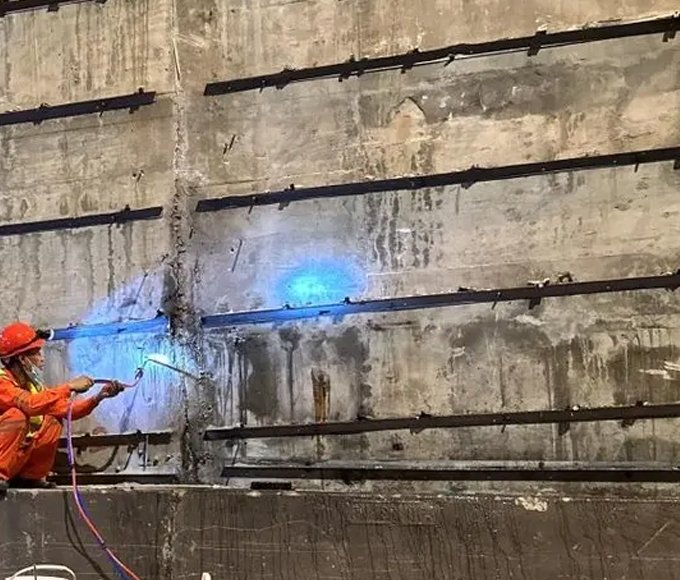

6. Case Insights: Successful Waterproof Coating Applications in Tunnel Projects

Real-world examples demonstrate how coating selection and supplier collaboration determine project success.

- Metro Tunnel, Southeast Asia – Polyurethane waterproof coatings by YURU Waterproof were used for lining a 3.2 km underground tunnel. The system provided rapid installation and zero leakage during hydrostatic pressure testing.

- Mountain Highway Tunnel, Western China – A combination of polyurethane and injection grouting systems sealed construction joints effectively, reducing water ingress by 95%.

These cases underscore YURU’s expertise in tailoring systems to geological conditions and offering consistent supply for multi-phase projects.

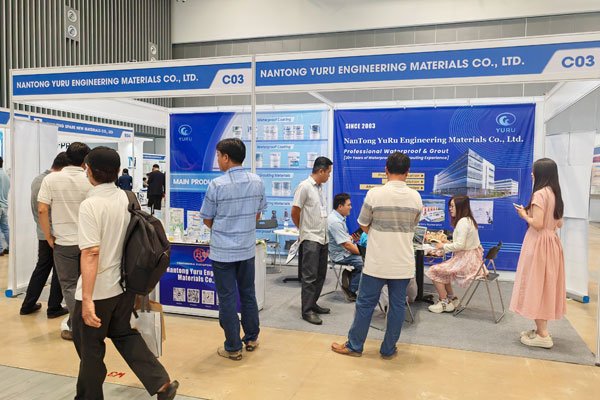

7. Why YURU Waterproof is a Trusted Supplier for Tunnel and Metro Projects?

YURU Waterproof has earned its position as a global partner for infrastructure waterproofing through continuous innovation, technical rigor, and commitment to sustainability.

Key advantages include:

- Comprehensive product portfolio: Polyurea, PU, epoxy, cementitious, and grouting systems.

- OEM & ODM service: Custom formulation, private labeling, and package design.

- ISO-certified manufacturing: Ensuring consistency and compliance.

- Strong R&D capabilities: Internal testing lab for accelerated aging and adhesion tests.

- Global export experience: On-time delivery and professional documentation.

- Technical service team: Field support, material training, and performance evaluation.

If you are seeking a long-term OEM partner or direct supplier for tunnel and metro waterproofing projects, YURU Waterproof can provide tailored solutions designed for durability, compliance, and ease of application.

FAQs

- What type of waterproof coating is best for tunnel construction?

Polyurea coatings are generally preferred due to their seamless finish, and excellent chemical resistance. For specific joints and maintenance areas, PU or epoxy coatings may be more suitable.

- Are water-based coatings suitable for underground environments?

Yes, if properly formulated. Modern water-based polyurethane coatings have strong adhesion and low VOC, making them safer for enclosed spaces like metro tunnels.

- What certifications should a waterproof coating supplier have?

Reputable suppliers should have ISO9001, ISO14001, and CE certifications, along with third-party test reports from organizations like SGS or Intertek.

- Can YURU Waterproof provide OEM or private-label production?

Yes. YURU offers OEM and ODM services including custom formulation, branding, and packaging for contractors and distributors.

- How long can a tunnel waterproofing system last?

When properly applied, premium polyurea or polyurethane systems can last over 25–40 years, depending on maintenance and environmental conditions.

- Does YURU Waterproof support international shipping and on-site guidance?

Yes. YURU exports globally with full export documentation and provides remote or on-site technical assistance for OEM partners.

Conclusion

Looking for a reliable waterproof coating supplier for tunnels and metro projects?

Partner with YURU Waterproof — a globally trusted manufacturer offering OEM customization, technical support, and certified performance coatings engineered for extreme underground environments.

YURU Product solutions

Waterproof Coating

- One-component oil-based polyurethane waterproof coating

- One-component water-based polyurethane waterproof coating

- Two-component polyurethane waterproof coating

- Two-component 6.0Mpa polyurethane waterproof coating

- Transparent Waterproof Glue

- Nano Invisible Waterproof Agent

- Silicone Waterproof Coating

- Acrylic Waterproof Coating For Metal Roof

- JS Polymer Waterproof Coating

- High Elastic Liquid Rubber Waterproof Coating

- Cement-based Penetrating Crystallization Waterproof Coating