Where to Use Polyurea Grouting?

Where To Use Polyurea Grouting?

When it comes to advanced waterproofing and structural reinforcement, Polyurea Grouting stands out as a high-performance solution.

But one of the most common questions we hear from contractors, retailers, and project developers is: Where exactly can Polyurea Grouting be used? Understanding the right application environments and structural contexts is key to unlocking its full potential.

In this article, we’ll explore the top five areas where Polyurea Grouting proves to be most effective. Whether you’re planning large-scale infrastructure projects or managing commercial waterproofing tasks, knowing where to apply this material can help you make smarter decisions, save costs, and ensure long-lasting results.

What Types of Structures Are Suitable for Polyurea Grouting?

Polyurea Grouting is engineered to provide exceptional structural reinforcement and long-term waterproofing, making it ideal for a wide range of foundational and load-bearing structures. Its high bonding strength, flexibility, and chemical resistance allow it to be used effectively in demanding environments that traditional grouting materials cannot endure.

Here are the most common types of structures where Polyurea Grouting is widely applied:

| Structure Type | Application Purpose | Why Polyurea Grouting Works Well |

| Concrete Foundations | Structural reinforcement, crack filling, waterproofing | High adhesion to concrete, rapid curing, durable performance |

| Tunnels and Subways | Leak sealing, joint protection, structural sealing | Resistant to hydrostatic pressure and ground movement |

| Basements and Underground Rooms | Waterproof lining, structural repair | Excellent water resistance and seamless membrane formation |

| Water Tanks and Pools | Leak prevention, surface protection | Chemical resistance and elasticity for dynamic environments |

| Underground Utility Tunnels | Long-term protection from moisture and corrosion | Long lifespan, chemical resistance, ease of maintenance |

These applications are backed by real-world engineering case studies where Polyurea Grouting has proven to significantly extend the life of critical infrastructure. For example, in large metro tunnel systems, it has been used to stop persistent water infiltration while maintaining structural integrity under high pressure and vibration.

What Environmental Conditions Are Ideal for Polyurea Grouting?

One of the key advantages of Polyurea Grouting is its outstanding adaptability to extreme and complex environmental conditions. Unlike conventional grouting materials, it maintains stability and performance even under moisture-heavy, chemically aggressive, or high-pressure environments.

Here’s a breakdown of ideal environmental conditions for Polyurea Grouting and why it performs well in each:

| Environmental Condition | Challenges Faced | Why Polyurea Grouting Performs Well |

| High Humidity or Wet Surfaces | Weak adhesion, slow curing in traditional grouts | Polyurea cures rapidly and bonds even on damp surfaces |

| Chemical Exposure (e.g. sewage, fuel) | Corrosive agents degrade materials over time | Excellent chemical resistance; ideal for industrial environments |

| Freeze-Thaw Cycles | Cracking and delamination | High elasticity prevents cracking and maintains adhesion |

| Heavy Water Leakage / Infiltration | Water pressure undermines standard sealants | Forms a seamless, flexible barrier that resists hydrostatic force |

Common use environments include:

- Bridges and highways, where exposure to salts, fuel, and moisture demands a robust and fast-curing seal.

- Hydraulic infrastructure such as dams, canals, and wastewater treatment plants, where long-term resistance to water and chemicals is critical.

- Underground and marine environments, which are constantly subjected to hydrostatic pressure and potential corrosive agents.

What Problems Can Polyurea Grouting Solve in Construction Projects?

Construction and infrastructure projects often face persistent issues that compromise both structural integrity and project efficiency. From water infiltration to surface cracking and voids beneath slabs, these challenges require a grouting solution that goes beyond basic sealing.

Polyurea Grouting is specifically formulated to tackle the most common — and costly — problems in modern construction. Here’s how it addresses key pain points:

| Construction Problem | Impact on Project | Polyurea Grouting Solution |

| Water Leakage / Infiltration | Structural damage, mold growth, service disruptions | Creates an impermeable, flexible barrier resistant to water |

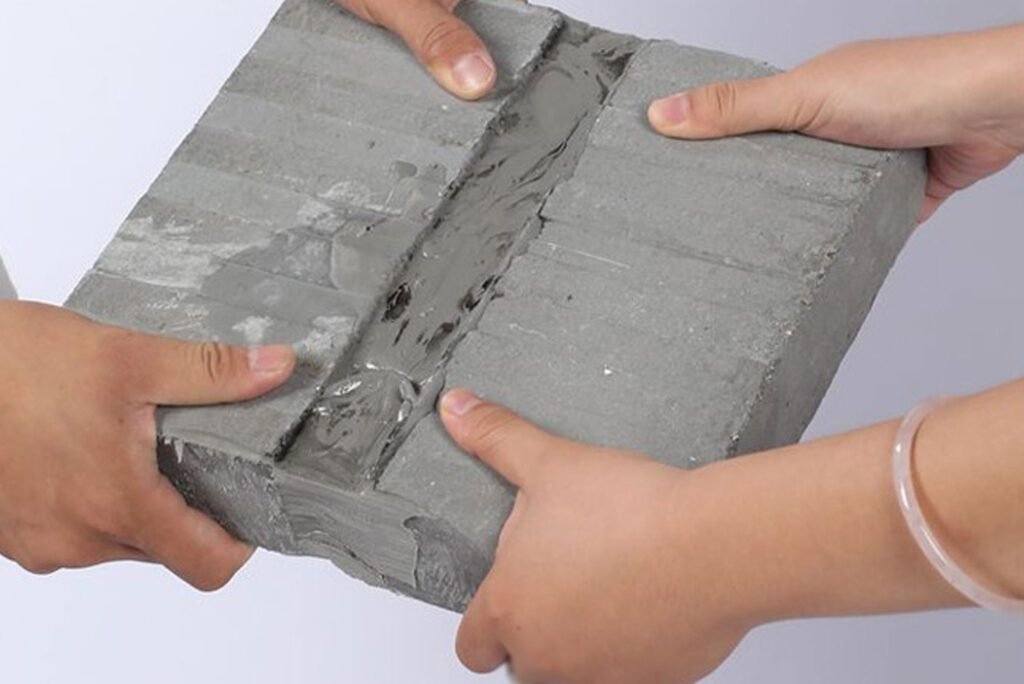

| Structural Cracks in Concrete | Safety risks, further degradation | Fills and seals cracks while bonding tightly to surfaces |

| Substrate Voids / Cavities | Uneven settlement, surface failure | Expands and fills voids, stabilizing base materials |

| Weak Joint Connections | Leakage, vibration, long-term structural fatigue | Forms elastic seals that absorb movement without failure |

| Chemical Degradation | Material breakdown, increased maintenance costs | High resistance to chemicals, oil, and aggressive agents |

How to Determine if Your Project Is Suitable for Polyurea Grouting?

Choosing the right grouting material depends on understanding the specific needs and conditions of your project. Polyurea Grouting is a high-performance solution, but like any specialized material, it shines best in the right scenarios.

To help you make informed decisions, we’ve outlined a simple checklist that evaluates key project factors.

Project Suitability Checklist for Polyurea Grouting

| Assessment Criteria | What to Evaluate | Why It Matters |

| Water Infiltration Level | Minor seepage vs. high-pressure leakage | Polyurea is ideal for active or aggressive water intrusion |

| Substrate Material | Concrete, steel, rock, or composite surfaces | Ensures strong adhesion and long-term performance |

| Environmental Exposure | Moisture, chemical agents, temperature fluctuations | Polyurea resists chemical degradation and thermal cycling |

| Structural Movement | Presence of expansion joints or vibration-prone areas | Polyurea’s elasticity prevents cracking or detachment |

| Project Budget | Need long-term durability | Cost-effective over time |

If your project meets three or more of the criteria above, Polyurea Grouting is likely a highly compatible and beneficial choice.

Pro Tip: Collect basic information such as site photos, leak patterns, structural materials, and expected environmental exposure. This helps your supplier provide accurate product recommendations and custom formulations.

At YURU Waterproof, we specialize in customized waterproofing and grouting materials. Our technical team can help you recommend tailored Polyurea Grouting solutions that match your specific project requirements — from bridges and tunnels to basements and industrial foundations.

Why YURU Waterproof?

At YURU Waterproof, we don’t just supply grouting materials — we partner with your business to ensure you deliver quality results.

From custom Polyurea formulations to technical consulting and bulk supply, we support your success across every project stage. Our flexible production and tailored support make us a preferred partner for resellers and construction professionals alike.

Conclusion

From deep underground tunnels to surface-level bridge decks, Polyurea Grouting has emerged as a versatile, top-of-the-line solution for numerous construction and waterproofing applications. It can tolerate very harsh environmental conditions, resist chemical degradation, and deliver fast, permanent protection, making it the leading option for new infrastructure projects.

By knowing where and when to apply Polyurea Grouting — and by assessing important factors such as structure type, moisture content, and urgency of the job — you will be making better, more economical decisions.

At YURU Waterproof, we are dedicated to providing customized grouting solutions for the specific needs of your project. Whether you have a requirement for bulk supply, custom formulations, or technical advice, our experts are poised and ready to assist you in proceeding.

Need assistance in selecting the correct product?

Reach out today and talk with a waterproofing specialist about how Polyurea Grouting will change your next project.